Roller type shot blasting machine

A shot blasting machine and drum-type technology, which is applied to surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of impurity falling off and shot blasting efficiency reduction, and reduce re- The effect of adhesion to the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

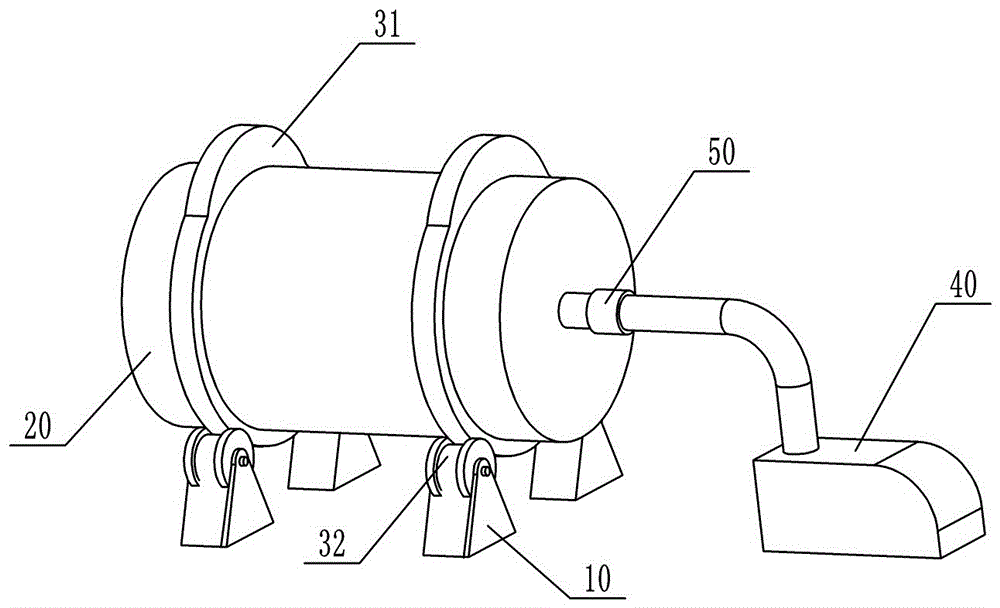

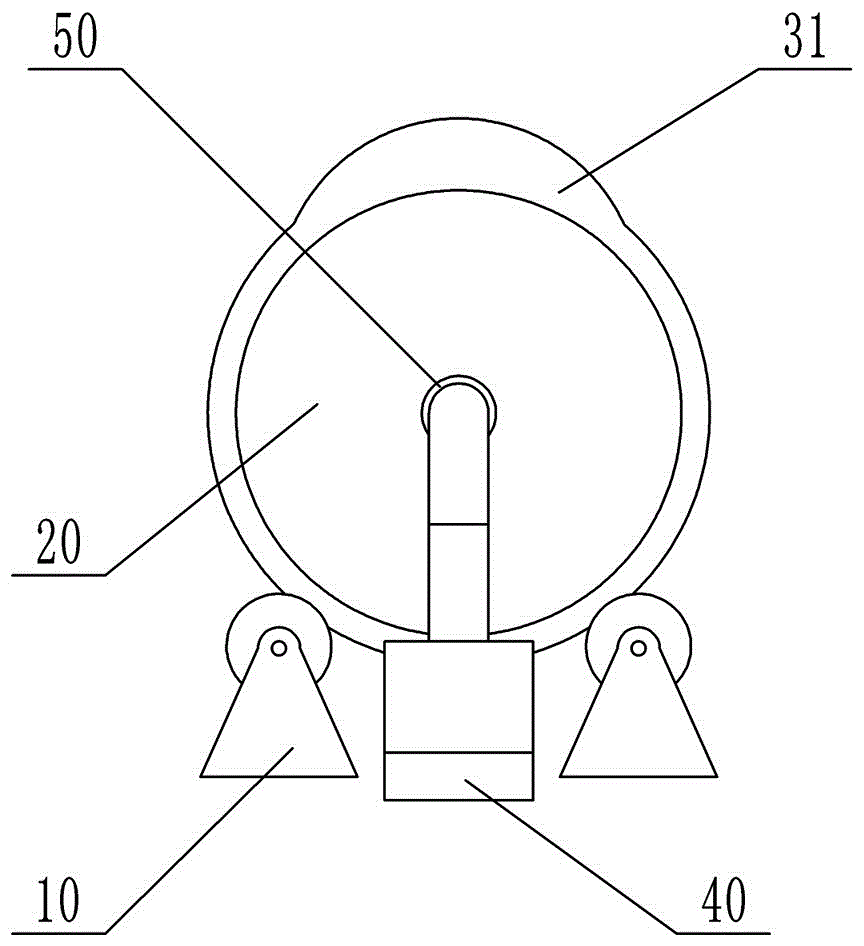

[0015] The reference signs in the drawings of the description include: base 10 , drum 20 , first friction wheel 31 , second friction wheel 32 , exhaust fan 40 , and rotary joint 50 .

[0016] like figure 1 , figure 2 As shown, the drum 20 type shot blasting machine includes a base 10, a first friction wheel 31, a second friction wheel 32 matched with the first friction wheel 31, a motor, a drum 20, an exhaust fan 40 and a rotary joint 50. The drum 20 is made of aluminum alloy, which has high strength, light weight and is not easy to rust. Steel shot is provided in the drum 20 . The first friction wheel 31 is sheathed on the surface of the drum 20 , and the second friction wheel 32 is mounted on the base 10 and pressed against the first friction wheel 31 . The second friction wheel 32 is provided with grooves, which can make the transmission between the first friction...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap