Robot capable of accomplishing complete assembly work

A technology of assembly work and robotics, applied in the direction of manipulators, metal processing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

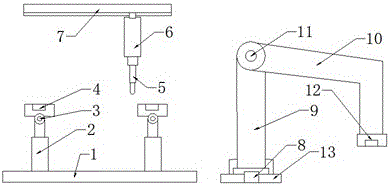

[0017] A robot that completes a complete set of assembly work, including: a workbench 1, a first telescopic rod 2 placed on the workbench 1, an electronic shaft 3 placed on the first telescopic rod 2, placed on the electronic shaft 3 and used to fix assembly components The vacuum chuck 4 placed on the upper end of the assembly component is placed on the electric screwdriver 5, the moving assembly that fixes the electric screwdriver 5 is placed next to the workbench 1 and the transport assembly that transports the assembly element.

[0018] The moving assembly consists of: a second telescopic rod 6 placed on the electric screwdriver 5 , and a guide rail 7 connected to the second telescopic rod 6 . There are two first telescopic rods 2 , and the line connecting the center points of the two first telescopic rods 2 is parallel to the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com