A groove line extrusion stand for a folding box pasting apparatus

A technology of extrusion table and folding box, which is applied in the direction of box making operation, paper/cardboard container, container, etc., can solve the problems of equipment length and manufacturing cost increase, and take a long time, so as to save space and improve processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Embodiment: Hereinafter, an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

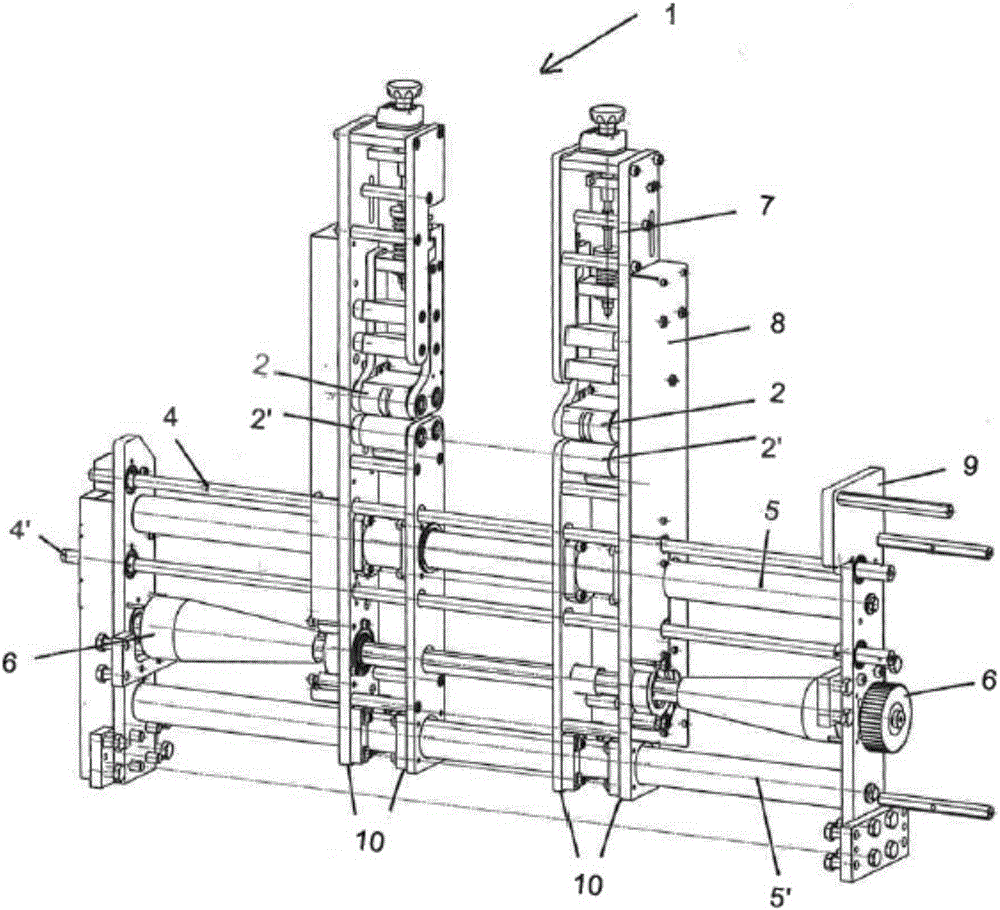

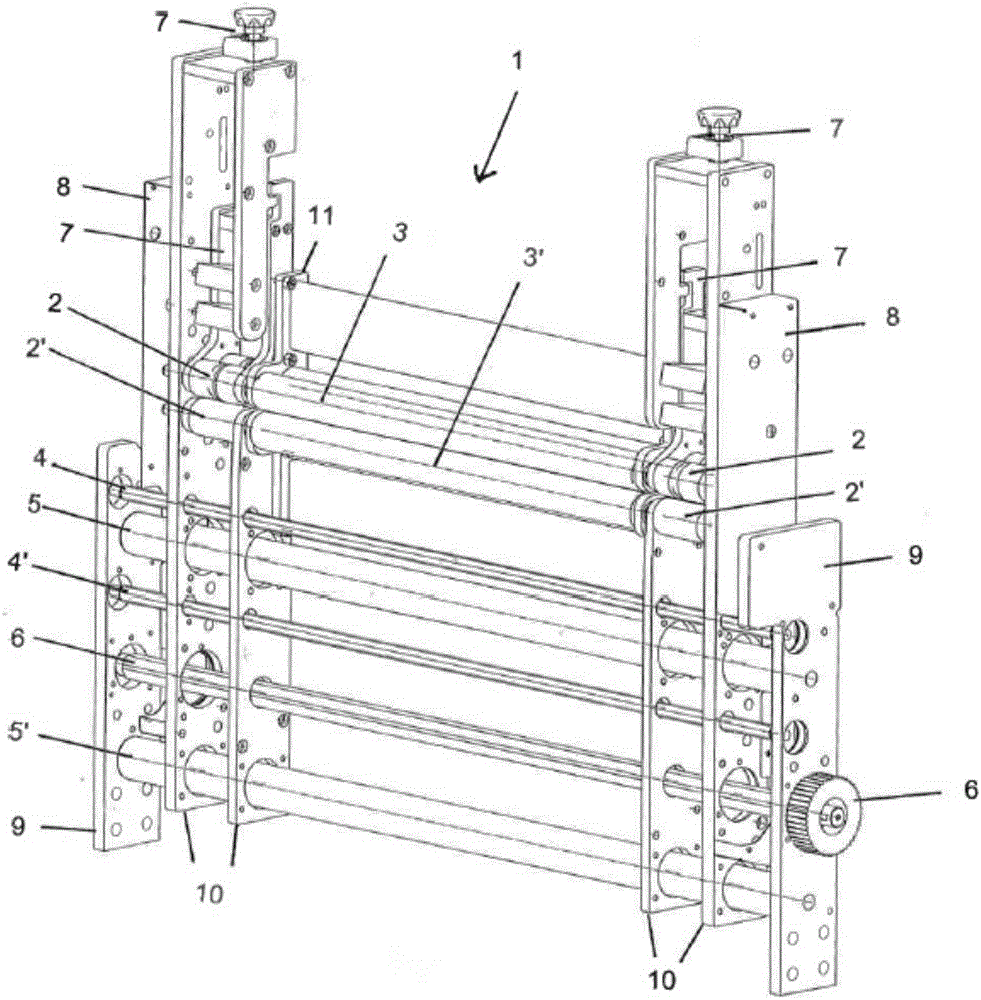

[0028] figure 1 The structure of a groove line extrusion station for processing folded blanks made of solid cardboard according to the state of the art is shown.

[0029] The folded blank passes with its groove line region a pair of side press rollers 2, 2', which has an upper press roller 2 and a lower press roller 2'. The squeeze rollers are driven by a drive belt (not shown) serving as drive means 6 .

[0030] By means of the mechanical device 4, 4', the position of the side pressing rollers 2, 2' can be changed in the transverse direction, so that blanks of different widths can be processed. In the embodiment shown, the lateral press rollers are fixed by means of bearings 5, 5'. The distance between the side extrusion rollers to 2, 2' can be adjusted for the blank thickness to be processed by the side extrusion roller height a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com