Double-rail flaw detecting car for subway steel rails

A steel rail flaw detection vehicle and double-track technology, which is applied to railway inspection vehicles, railway car body parts, railway vehicle shape measuring instruments, etc. Quality, compact and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

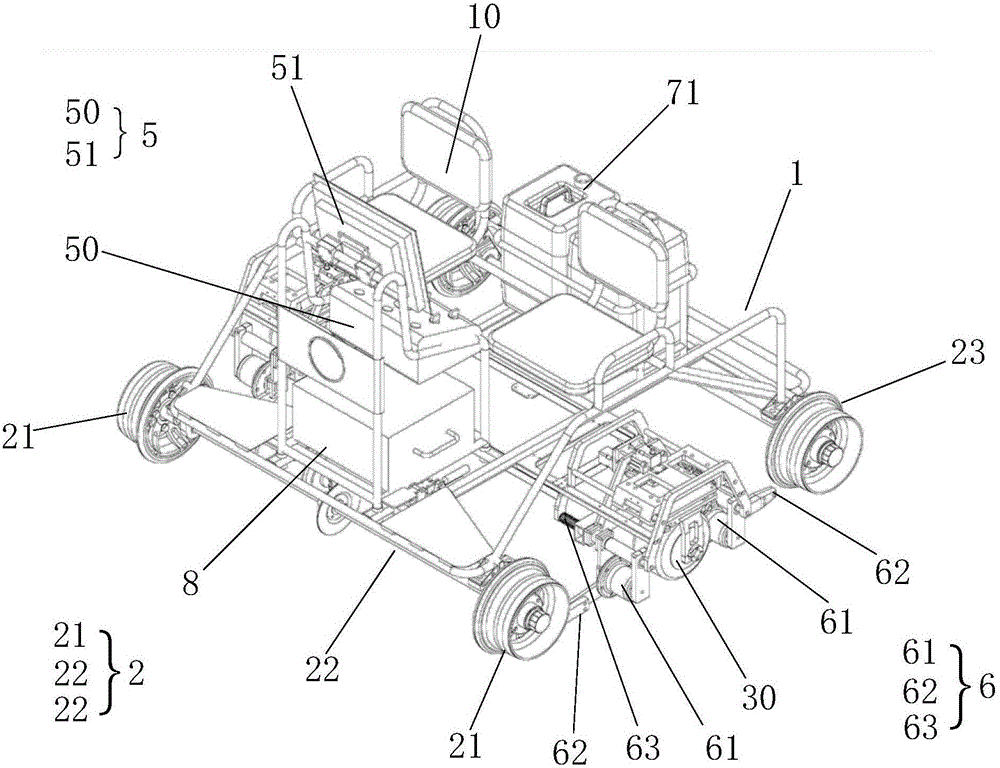

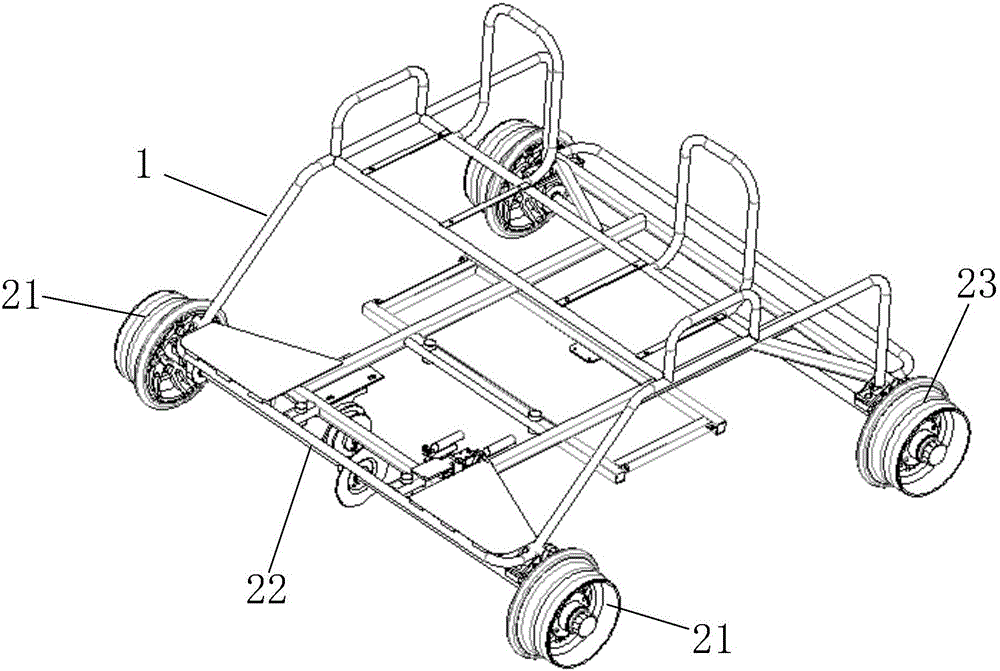

[0039] The following will combine Figure 1 to Figure 8 A detailed description of the subway double-track steel rail flaw detection vehicle provided by the present invention is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and polish it without changing the spirit and content of the present invention. .

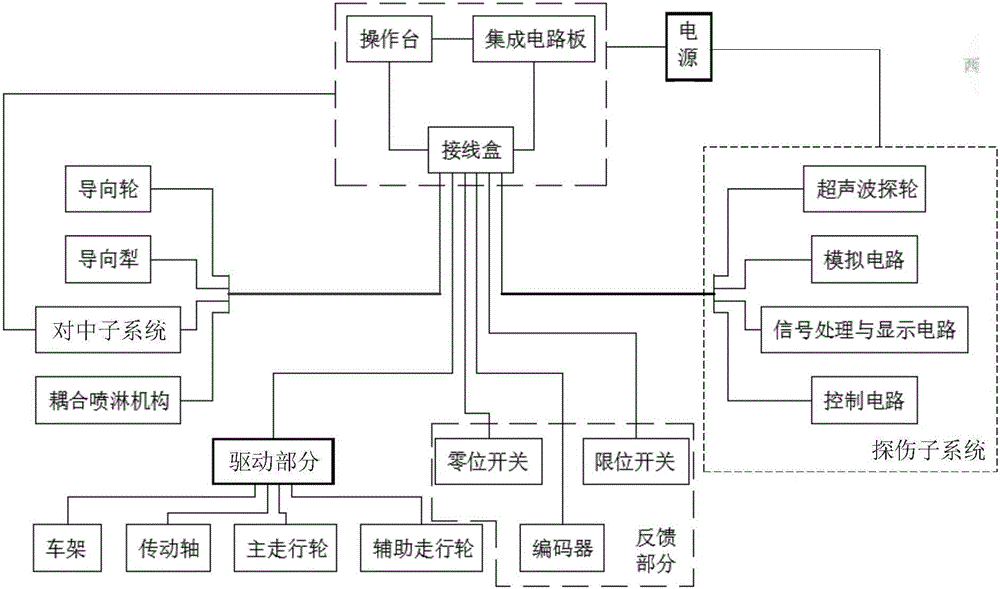

[0040] Please refer to Figure 1 to Figure 8 , The present invention provides a subway double-track rail flaw detection vehicle, which includes a frame 1, a traveling subsystem 2, a flaw detection subsystem 3, a centering subsystem 4, and a control subsystem 5. The traveling subsystem 2, the flaw detection subsystem 3 , The centering subsystem 4 and the control subsystem 5 can be detachably installed on the frame 1; in a preferred embodiment of the present invention, the frame 1 can be formed by welding or plugging and connecting with round pipes. The various subsystems are connected to the basic frame 1 in a remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com