Layered pressure regulating submersible and manufacturing method thereof

A manufacturing method and technology of submersibles, applied to underwater ships, underwater operating equipment, ships, etc., can solve problems such as low safety factor and reduced fatigue life, so as to increase fatigue life, reduce stress level, and reduce preparation process requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

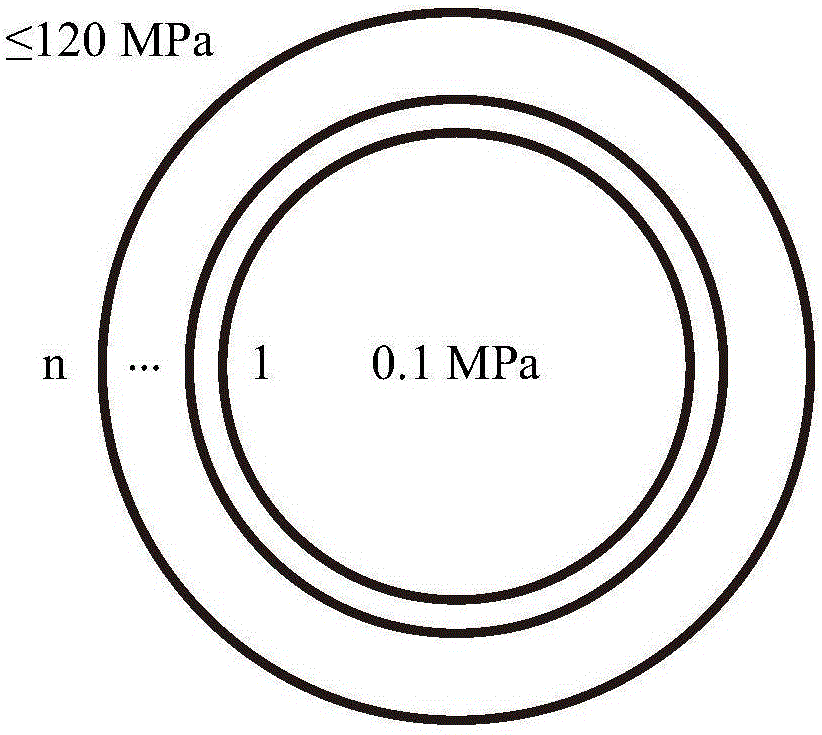

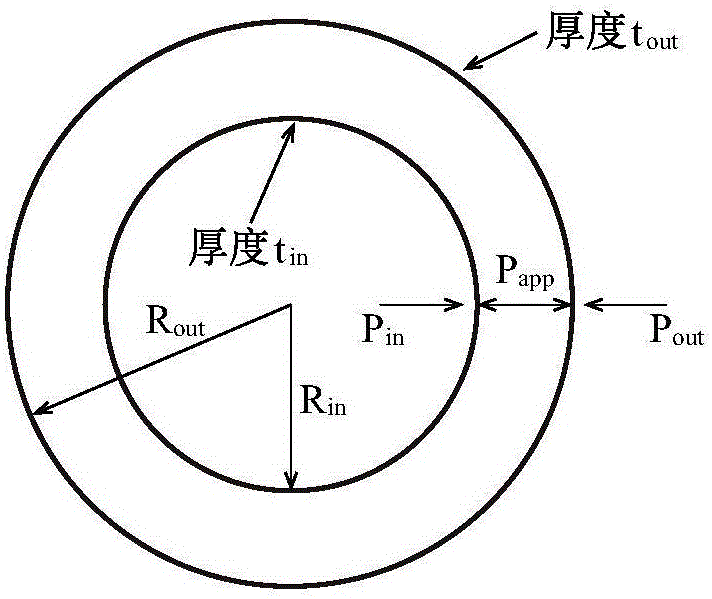

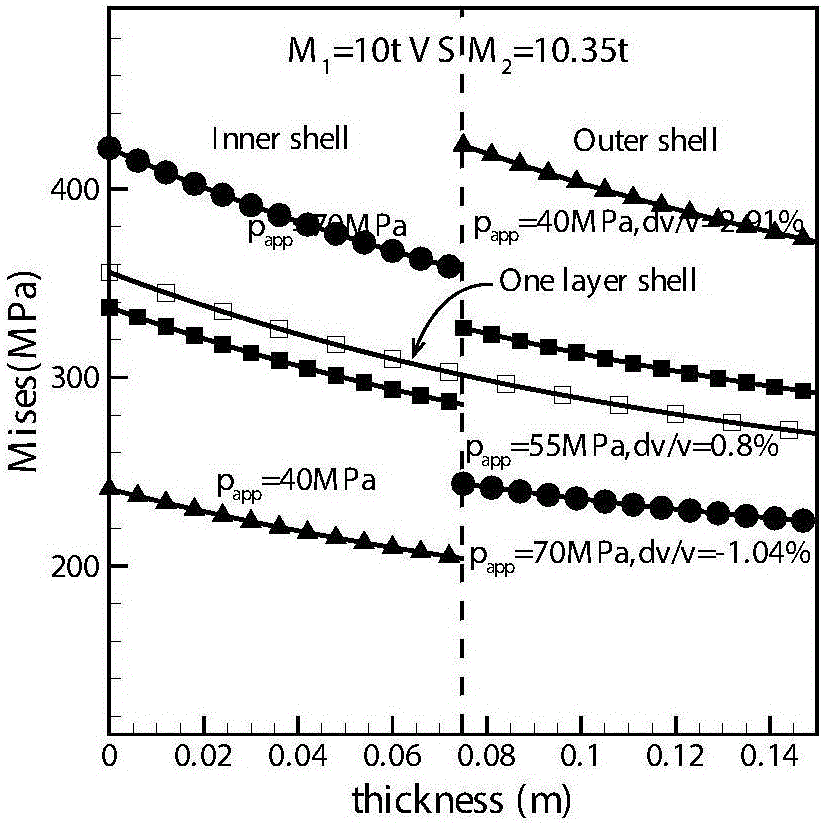

[0019] From the mechanical design point of view, the key mechanical issues of the pressure vessel involve elastic instability and plastic yielding. From the perspective of elastic instability, the lattice material sandwich structure composed of three-dimensional space micro-truss structure has the characteristics of high specific stiffness, specific strength, and multi-functionality, which can effectively improve the buckling resistance of the pressure cabin structure. The structural design of the layered pressure compartment based on interlayer pressure can decompose the ultra-high pressure in the deep sea and share it evenly between the inner and outer shells, significantly reducing the stress level of the shell and improving the plastic yield safety factor of the pressure cabin , thereby effectively increasing the fatigue life. Therefore, the layered partial pressure chamber based on interlayer pressurization has broad development prospects.

[0020] The layered pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com