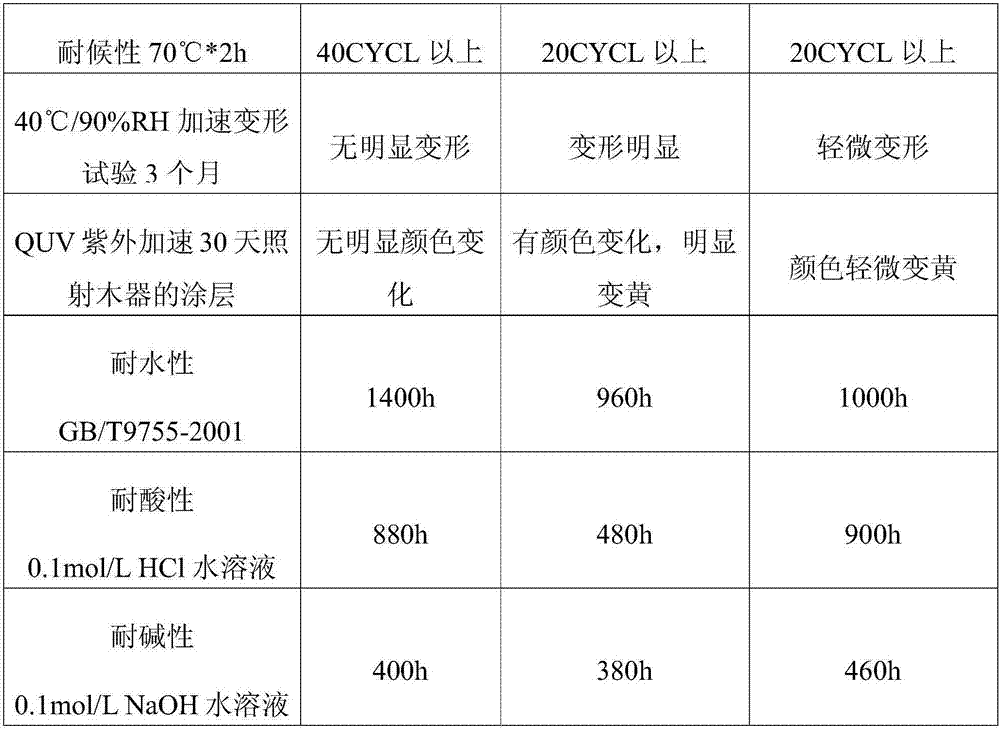

A kind of wood wax oil and preparation method thereof

A wood wax oil and vegetable oil technology, applied in wax coatings, coatings, anti-corrosion coatings, etc., can solve problems such as poor weather resistance and achieve the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Wood wax oil component, by weight:

[0043] 79 parts of vegetable oil, described vegetable oil is made up of 18 parts by weight linseed oil, 12 parts by weight castor oil, 7 parts by weight peanut oil, 9 parts by weight linseed oil; 13 parts of vegetable wax, described vegetable wax is made up of 27 parts by weight of candelilla wax , 13 parts by weight carnauba wax, 16 parts by weight sugarcane wax form; 5 parts of cosolvents, described cosolvents are made up of 3 parts by weight benzyl alcohol, 7 parts by weight butylparaben, 9 parts by weight ethanol, 6 parts by weight n-butanol Composition; 3 parts by weight of blending agent, said blending agent is made up of 3 parts by weight of micropowdered silica gel microcrystalline cellulose, 1 part by weight of cyclomethicone, and 2 parts by weight of diethanolamine; 0.3 parts of drier, said drier It consists of an active drier and an auxiliary drier with a weight ratio of 3:1, wherein the active drier is ferric citrate, and...

Embodiment 2

[0061] Wood wax oil component, by weight fraction: 82 parts of vegetable oils, described vegetable oil is made up of 18 parts of linseed oils, 12 parts of castor oils, 7 parts of peanut oils, 9 parts of linseed oils by weight; 15 parts of vegetable waxes, so Described vegetable wax is made up of 27 parts by weight candelilla wax, 13 parts by weight carnauba wax, 16 parts by weight sugarcane wax; 9 parts by weight of ethanol, 6 parts by weight of n-butanol; 5 parts by weight of a blending agent consisting of 3 parts by weight of micropowdered silica gel microcrystalline cellulose, 1 part by weight of cyclomethicone, and 2 parts by weight of diethanolamine; 0.5 parts of drier, the drier is composed of an active drier and an auxiliary drier in a weight ratio of 3:1, wherein the active drier is ferric citrate, and the auxiliary drier is zinc picolinate; 0.3 parts of modifying agent, described modifying agent is made up of 3 parts by weight of croscarmellose sodium, 5 parts by weig...

Embodiment 3

[0064] Wood wax oil components, by weight fraction: 80 parts of vegetable oil, 14 parts of vegetable wax, 5 parts of cosolvent, 4 parts of blending agent, 0.4 part of drier, and 0.2 part of modifier.

[0065] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap