A centralized waste gas treatment device for in-situ thermal regeneration machines

A centralized processing and regenerating machine technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve problems such as asphalt smoke pollution, environmental pollution, air pollution, etc., and achieve the effect of novel design concepts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

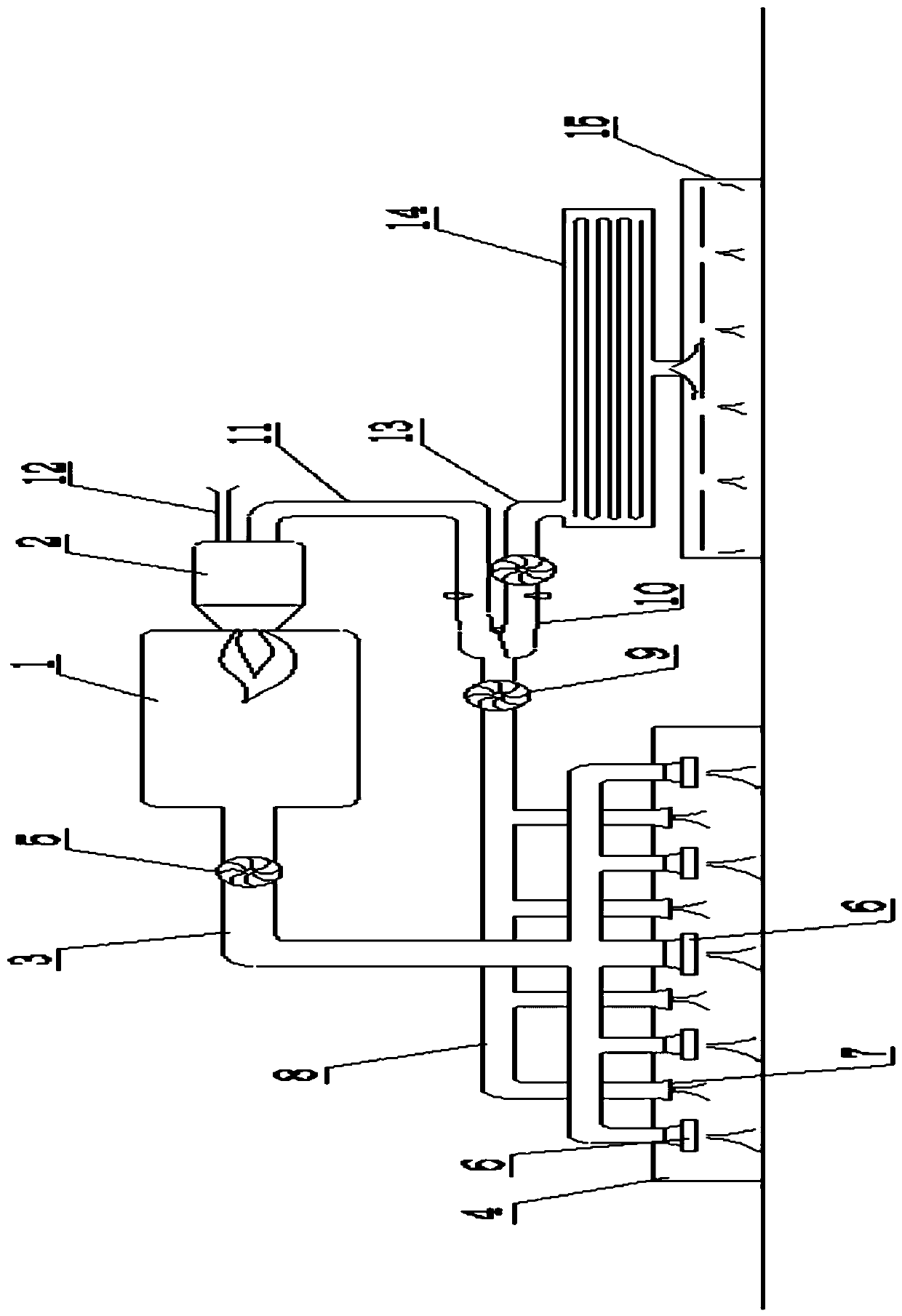

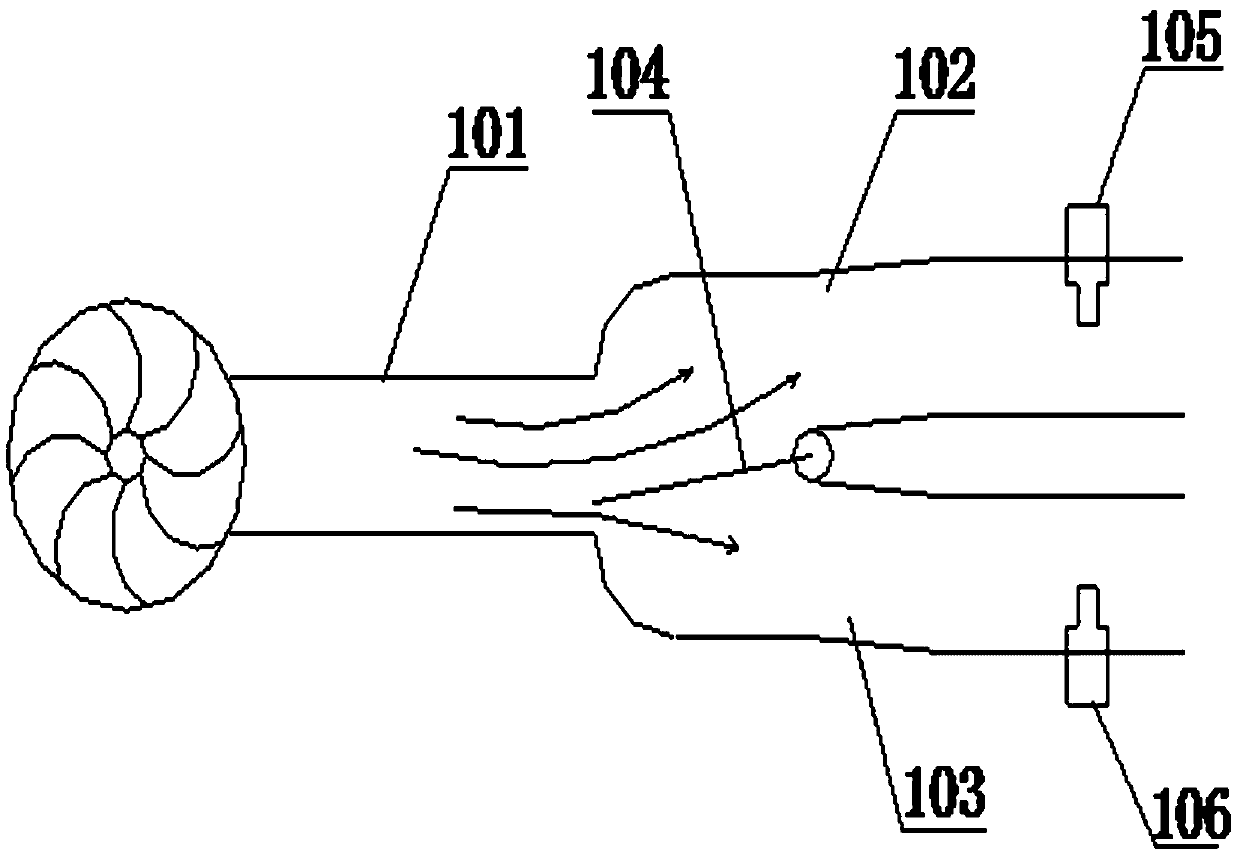

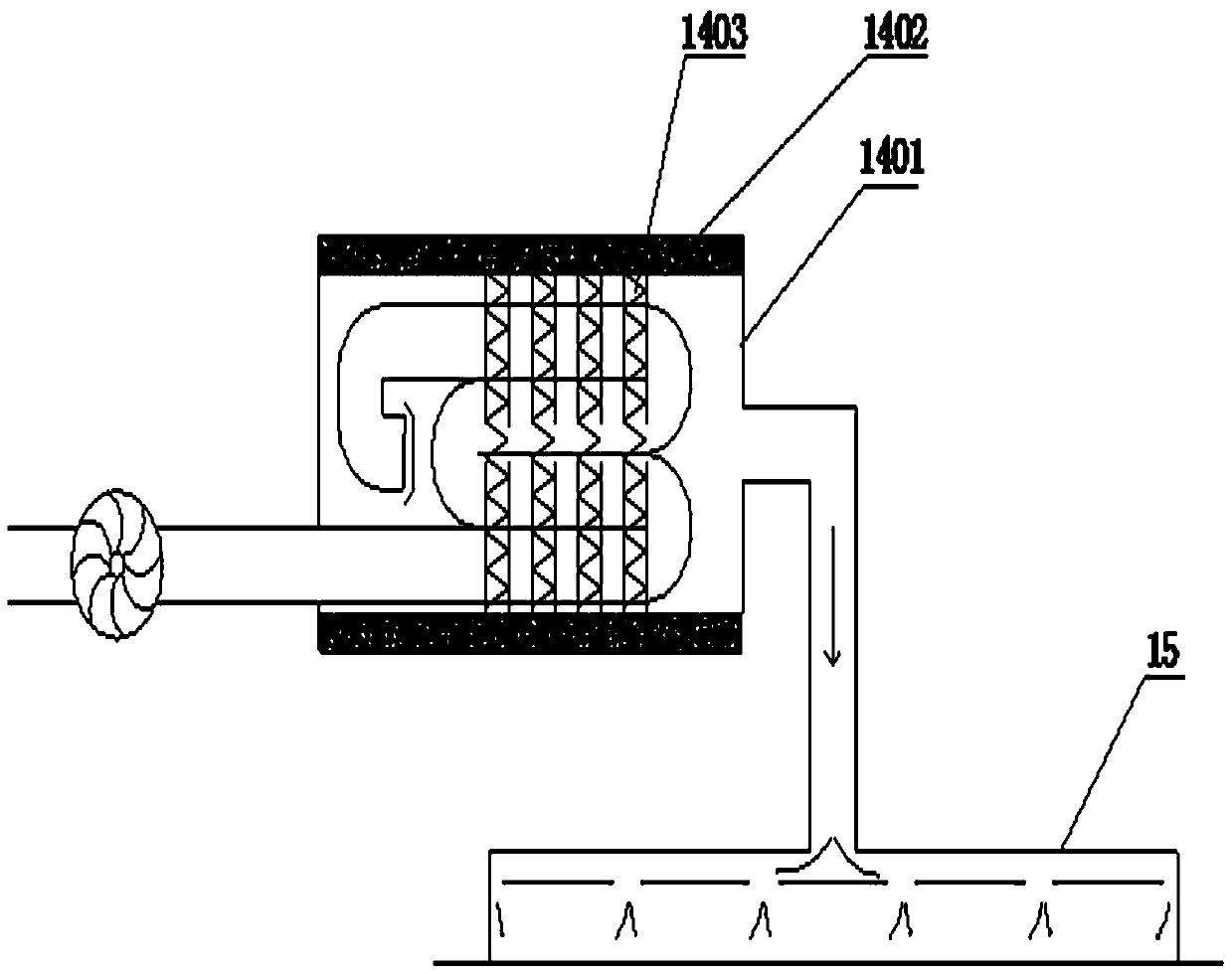

[0022] With reference to the accompanying drawings, a centralized waste gas treatment device for an in-situ thermal regenerator includes an air heater 1, one end of the air heater 1 is provided with a low-oxygen burner 2, and the other end of the air heater 1 is connected to an air outlet. One end of the duct 3 and the other end of the air outlet duct 3 are connected to the first pair of ground heating plates 4 , and a first induced draft fan 5 is arranged on the air outlet duct 3 . An air outlet 6 is arranged on the first pair of ground heating plates 4, and the air outlet 6 communicates with the air outlet duct 3; The air duct 8 is connected, and a second induced draft fan 9 is arranged on the return air duct 8 , and the end of the return air duct 8 is connected with an air volume distributor 10 . The air volume distributor 10 is connected to the low-oxygen burner 2 through the first delivery air channel 11, and the low-oxygen burner 2 is also connected with a fresh air inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com