Patents

Literature

32 results about "Thermal regenerator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

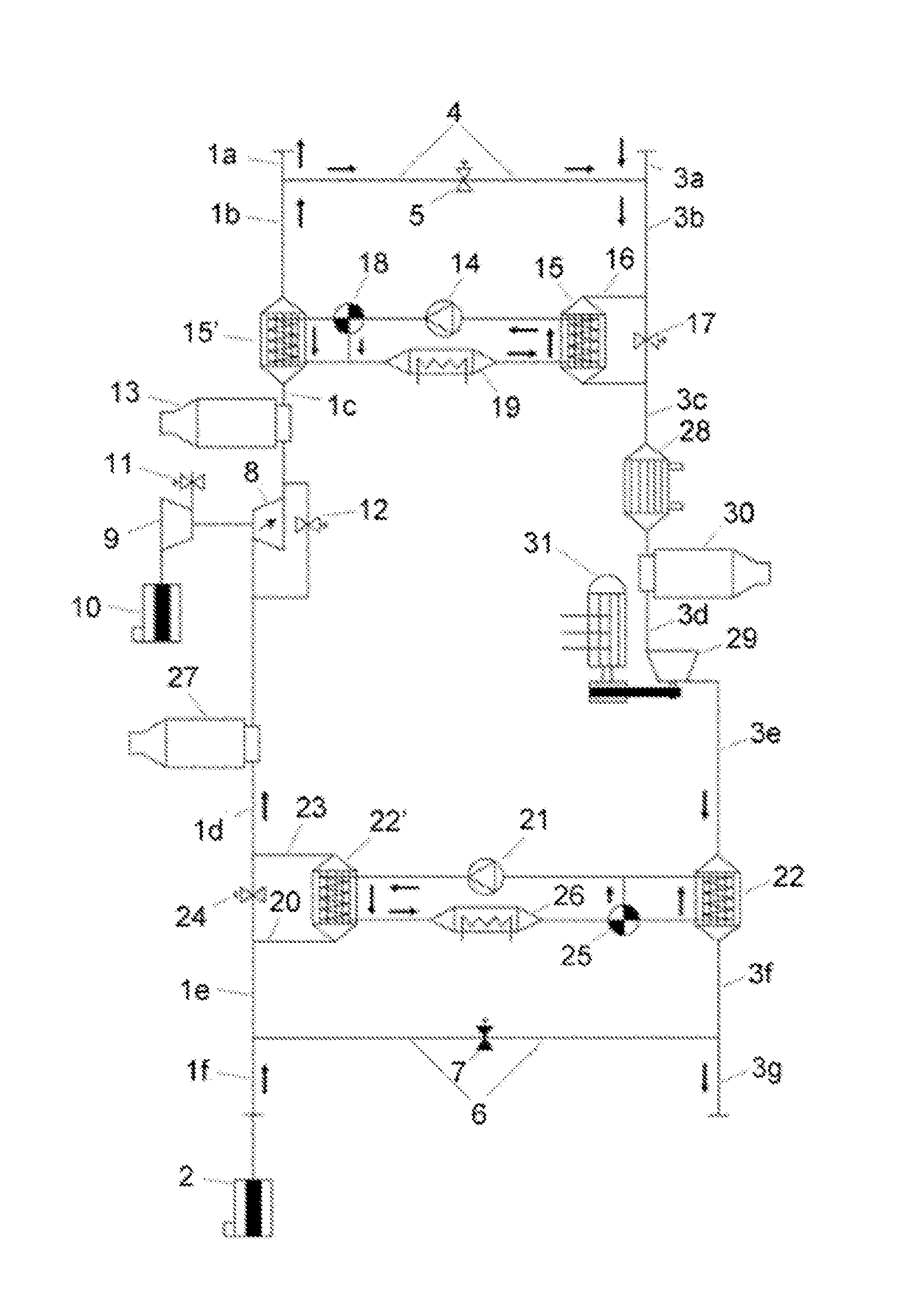

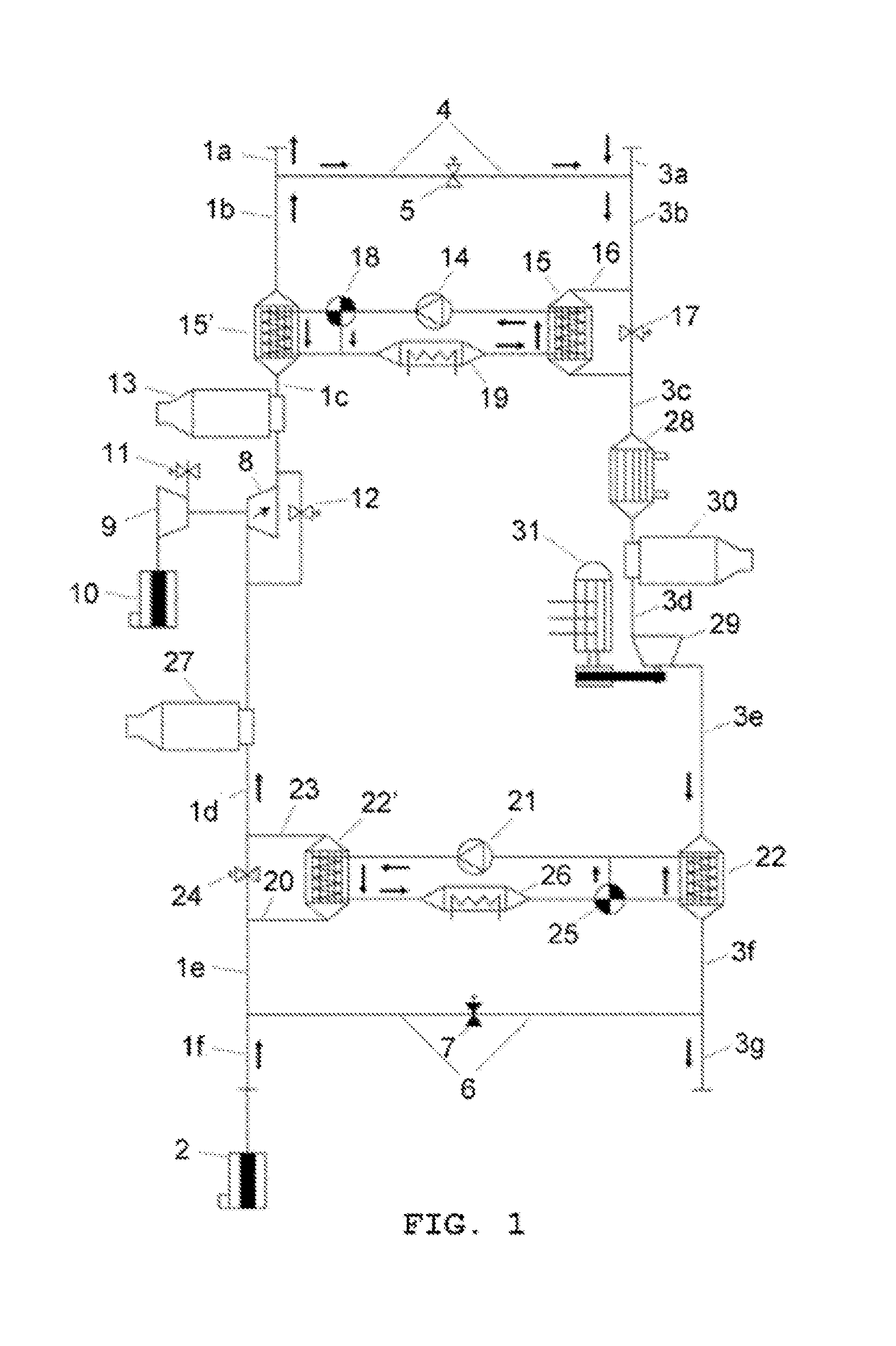

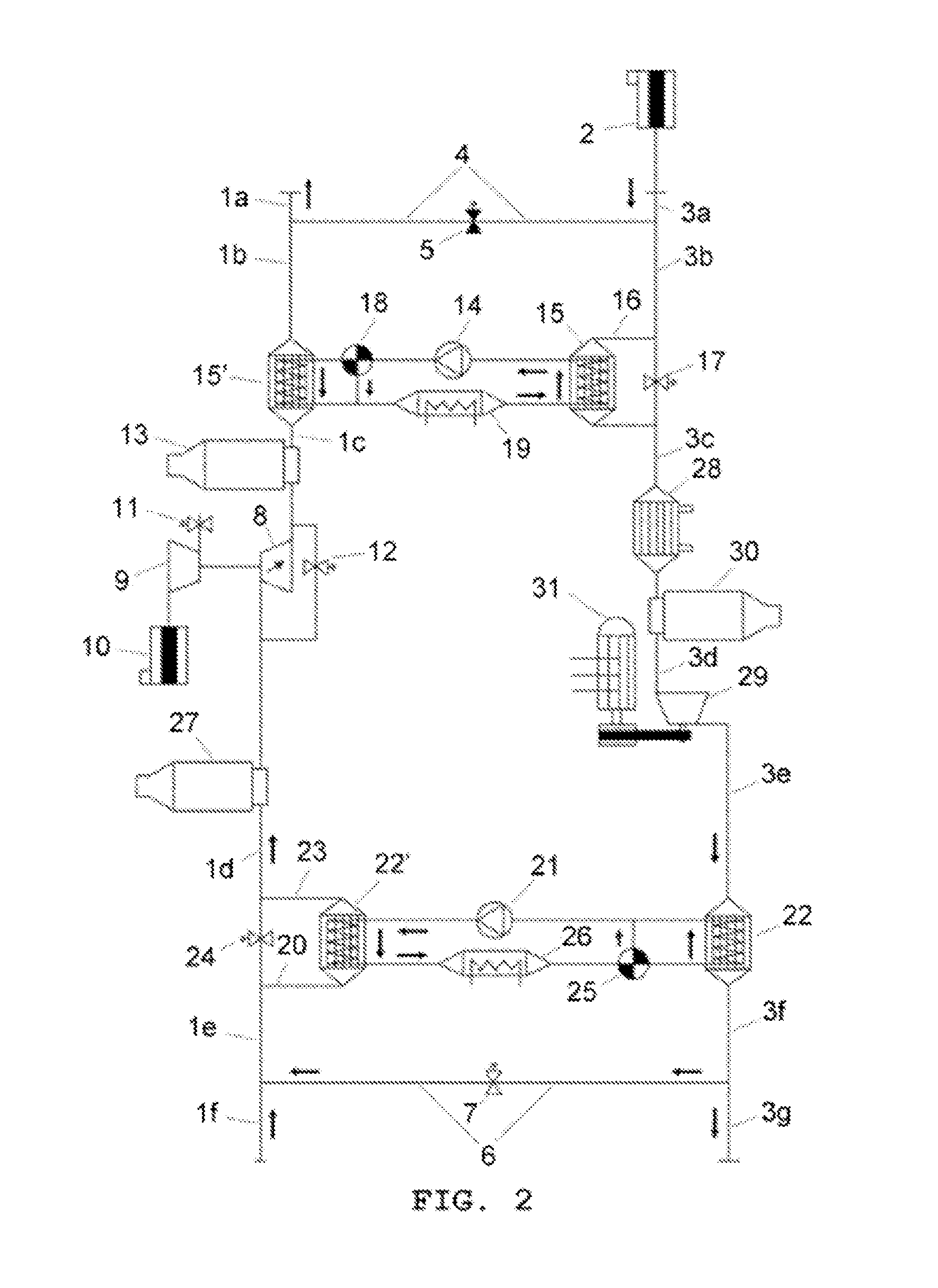

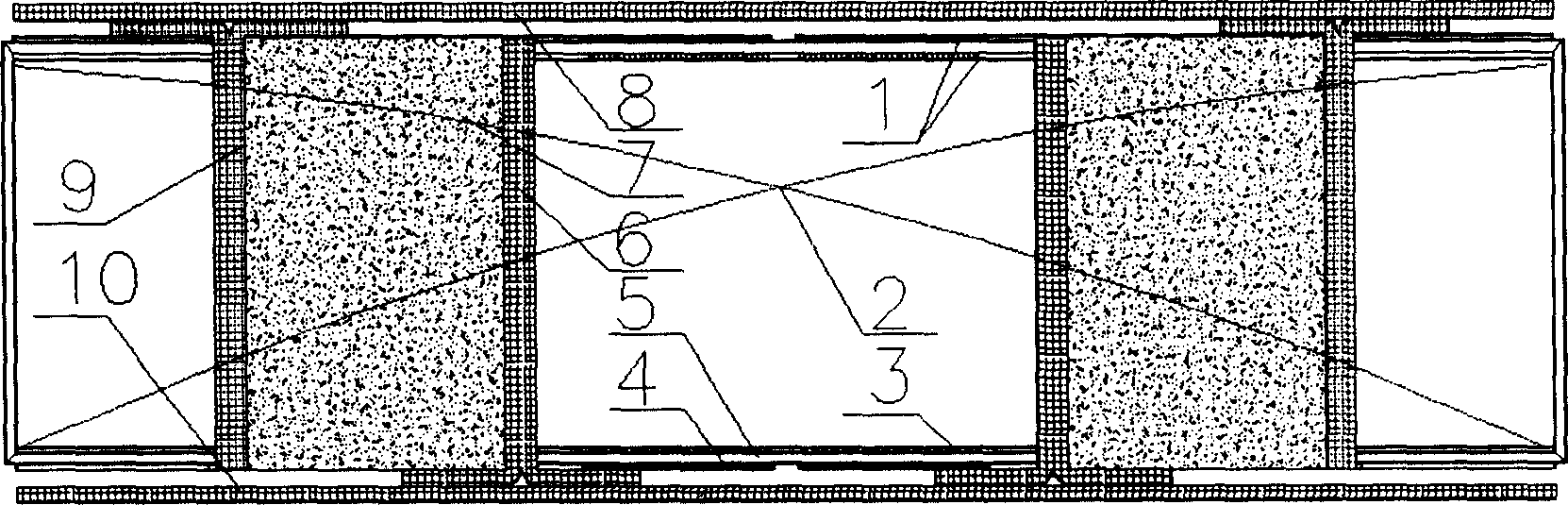

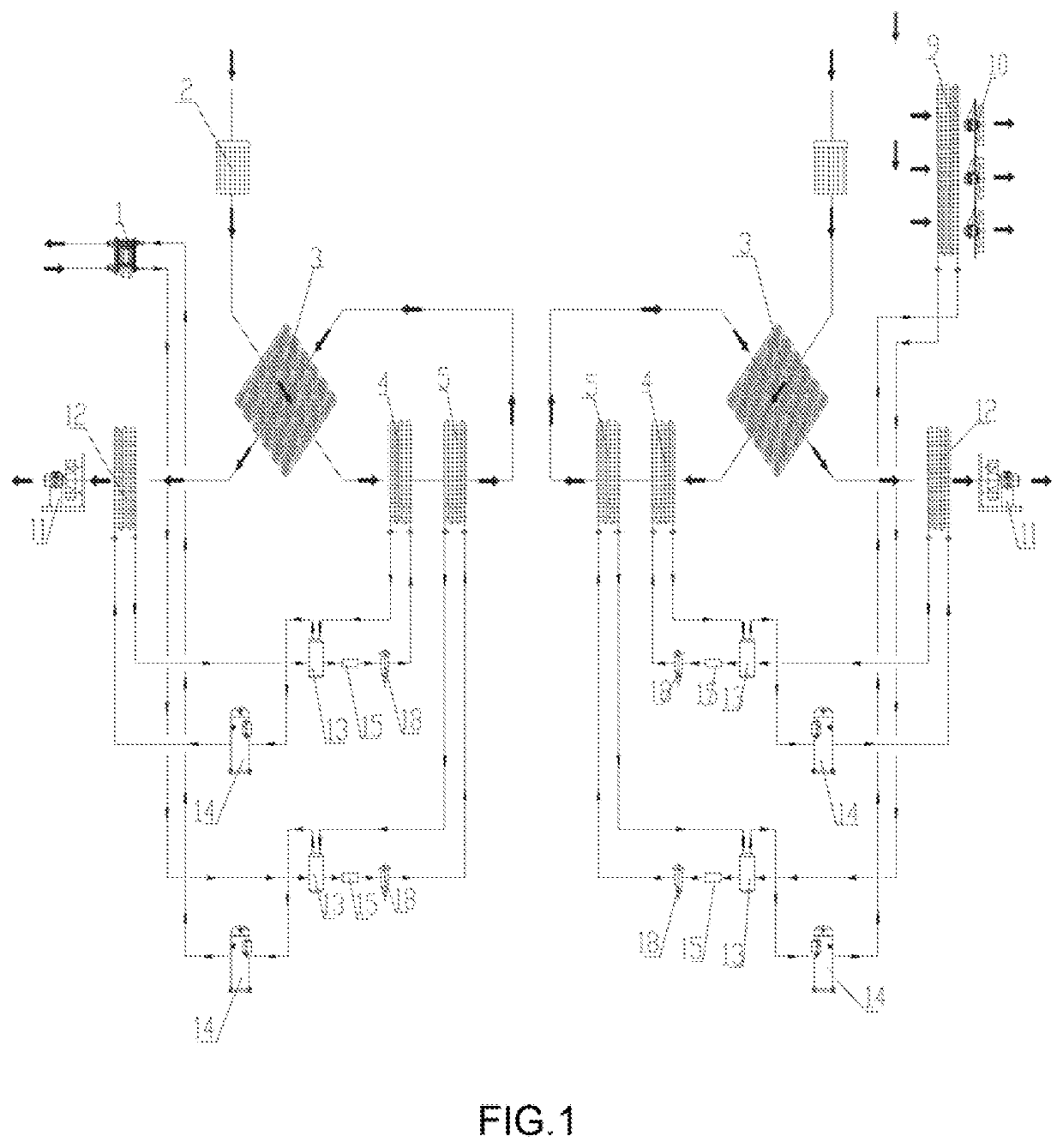

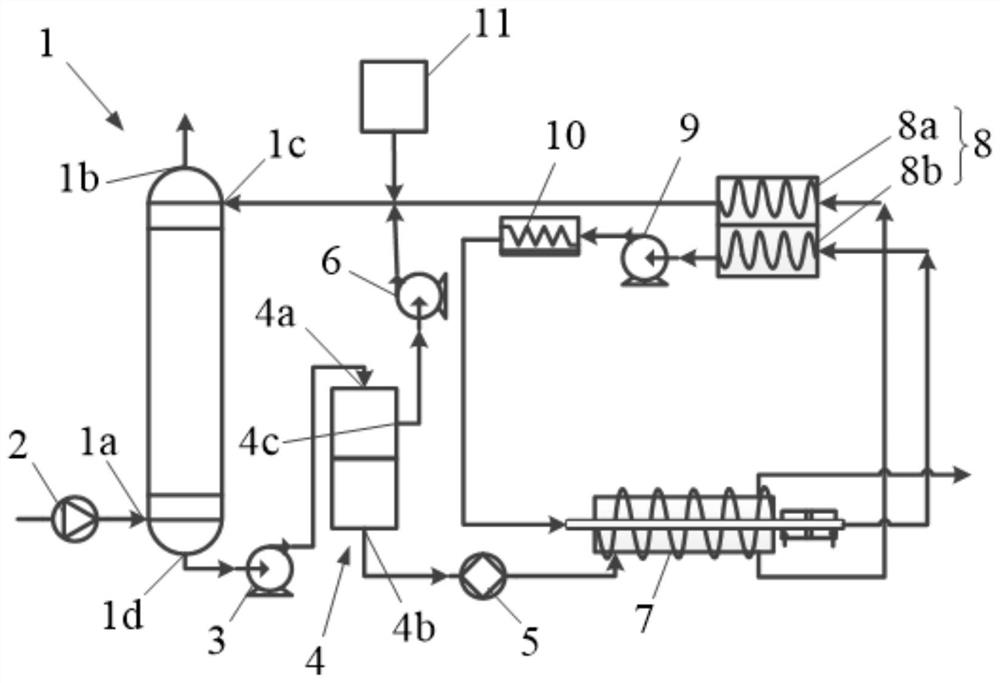

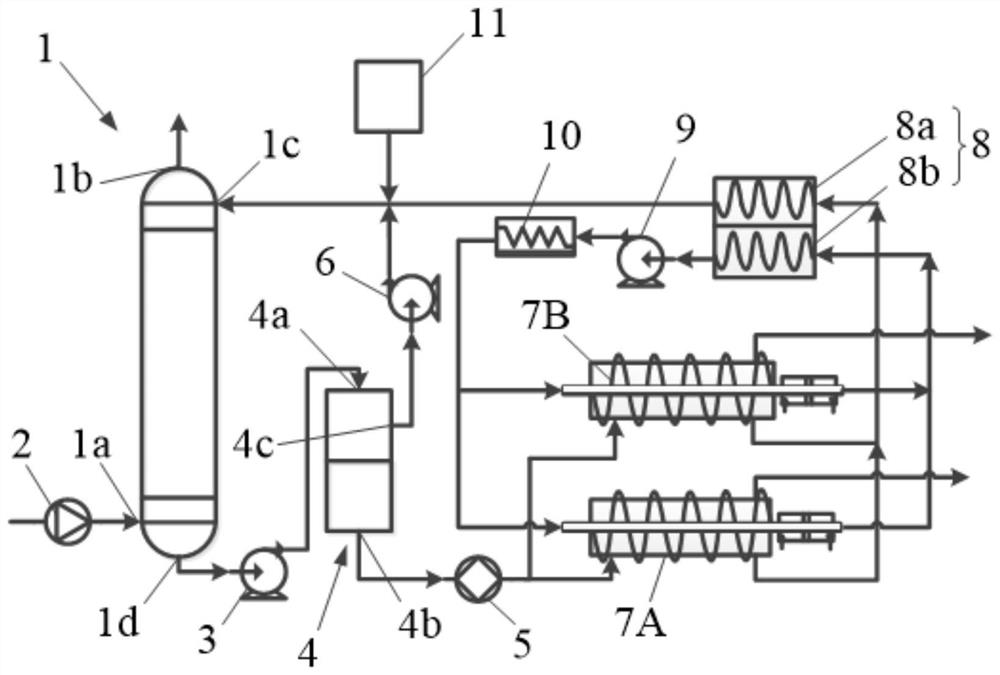

Switchable two-stage and cascade marine energy-saving ultralow-temperature refrigeration system

ActiveUS20160334143A1Save energyImprove efficiencyMechanical apparatusAuxillariesVapor–liquid separatorSolenoid valve

The present invention discloses a switchable two-stage and cascade marine energy-saving ultralow-temperature refrigeration system which comprises a high-temperature level refrigeration system, a low-temperature level refrigeration system, a hot fluorine defrosting system of a high-temperature level air cooler and a hot fluorine defrosting system of a low-temperature level air cooler. The hot fluorine defrosting system of the high-temperature level air cooler comprises a high-temperature level compressor of which the outlet is divided into two paths through a first oil separator; and the second path is connected with an air suction port of the high-temperature level compressor through a first solenoid valve, the high-temperature level air cooler, a third solenoid valve, a first pressure relief valve, a first gas-liquid separator, a first one-way valve and a first heat regenerator. The hot fluorine defrosting system of the low-temperature level air cooler comprises a low-temperature level compressor of which the outlet is divided into two paths through a precooler and a second oil separator; and the second path is connected with an air suction port of the low-temperature level compressor through an eighth solenoid valve, the low-temperature level air cooler, a sixth solenoid valve. a second pressure relief valve, a second gas-liquid separator, a third one-way valve and a second heat regenerator. The present invention has the obvious effects of large refrigeration section, high cooling rate, good energy-saving effect and thorough defrosting.

Owner:SHANGHAI OCEAN UNIV

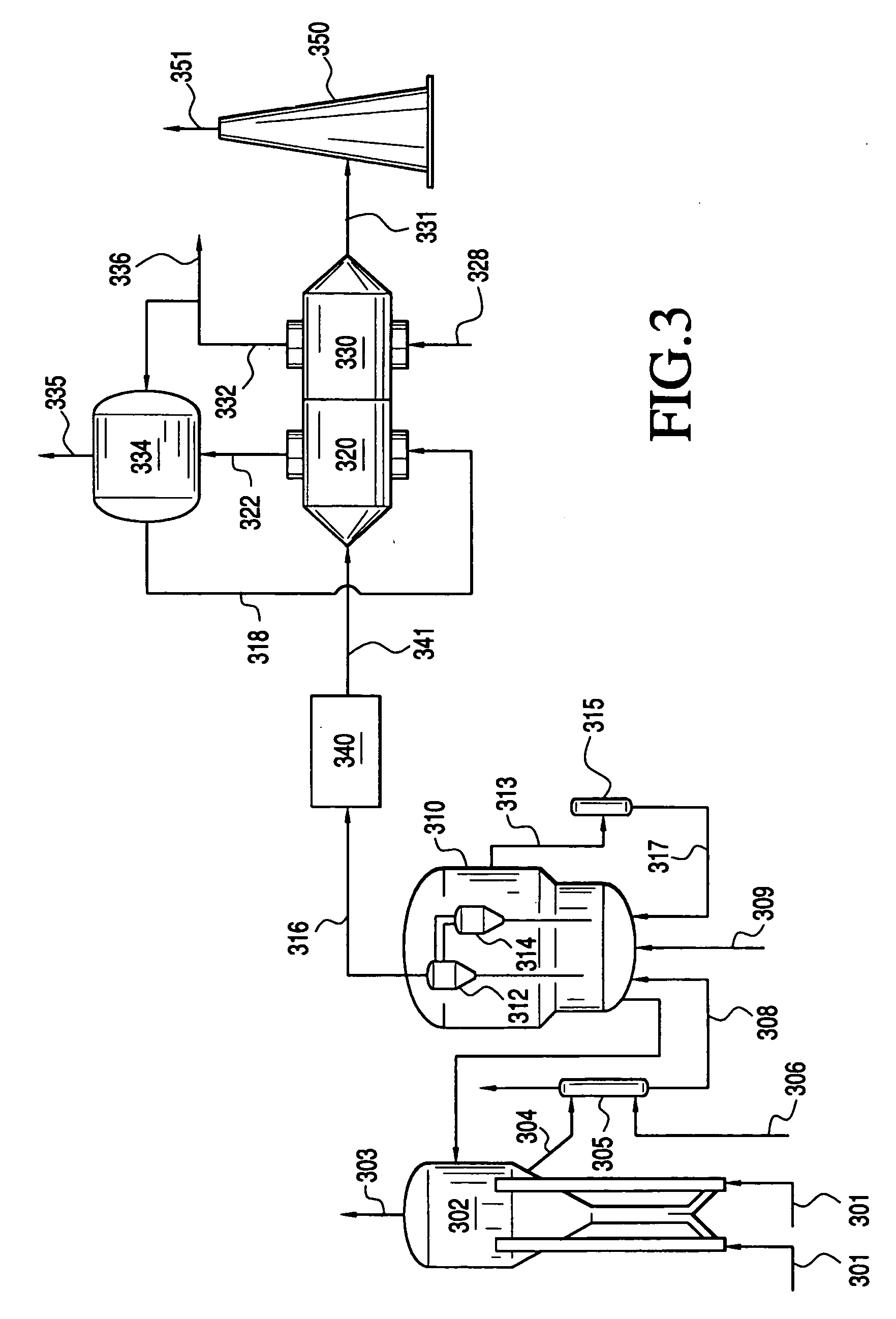

Heat recovery technique for catalyst regenerator flue gas

ActiveUS20050238548A1Effective recoveryIncrease steamThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

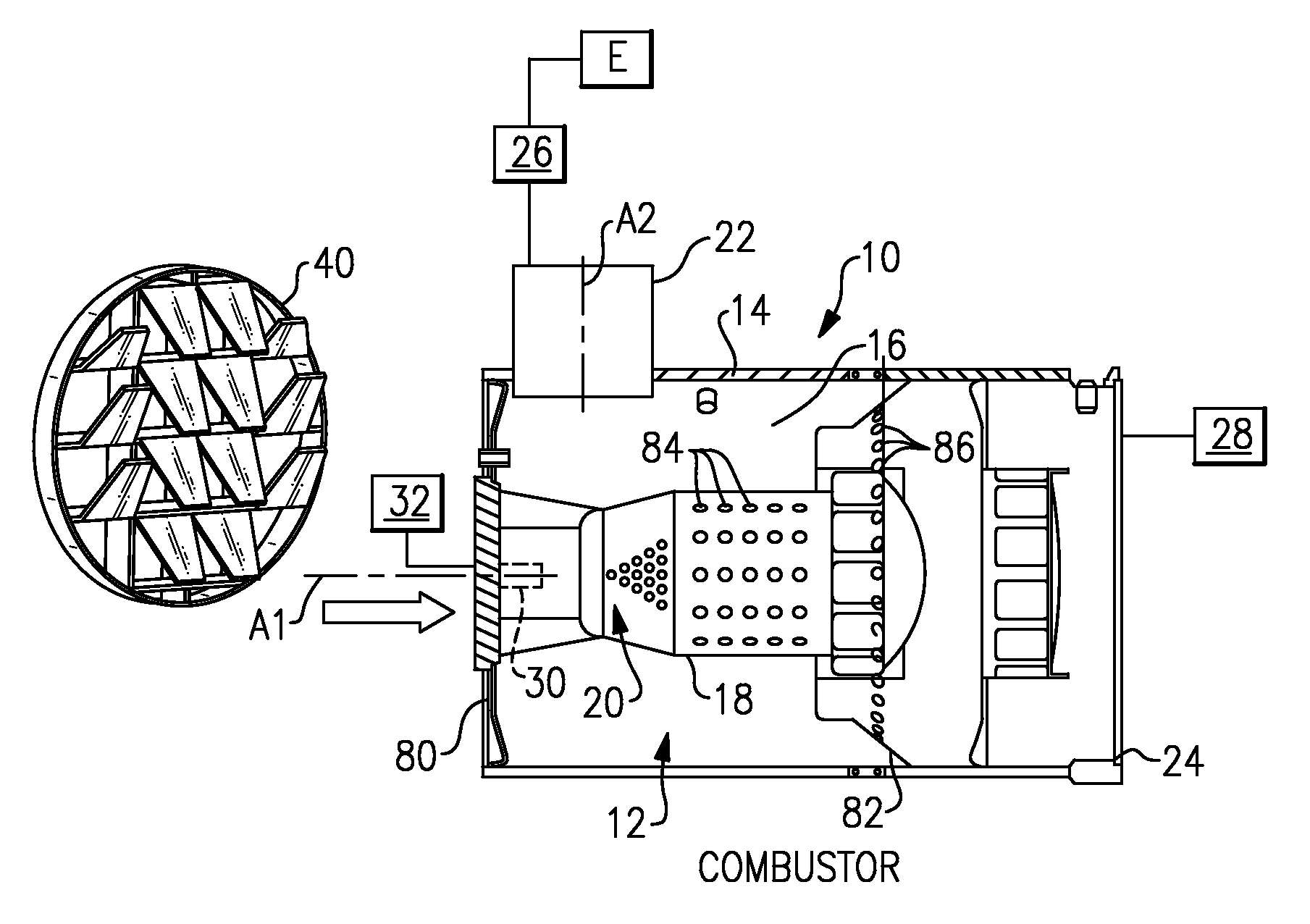

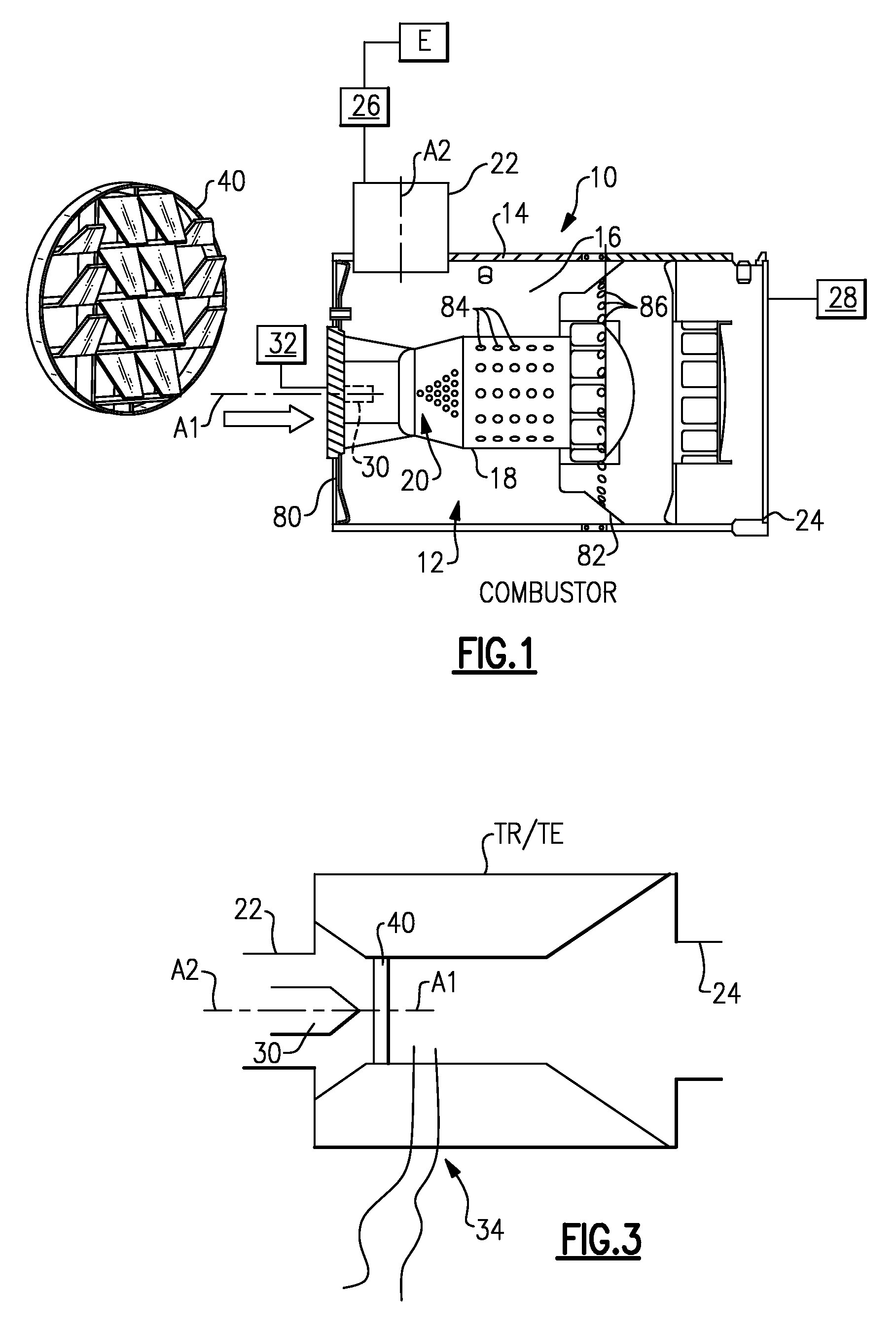

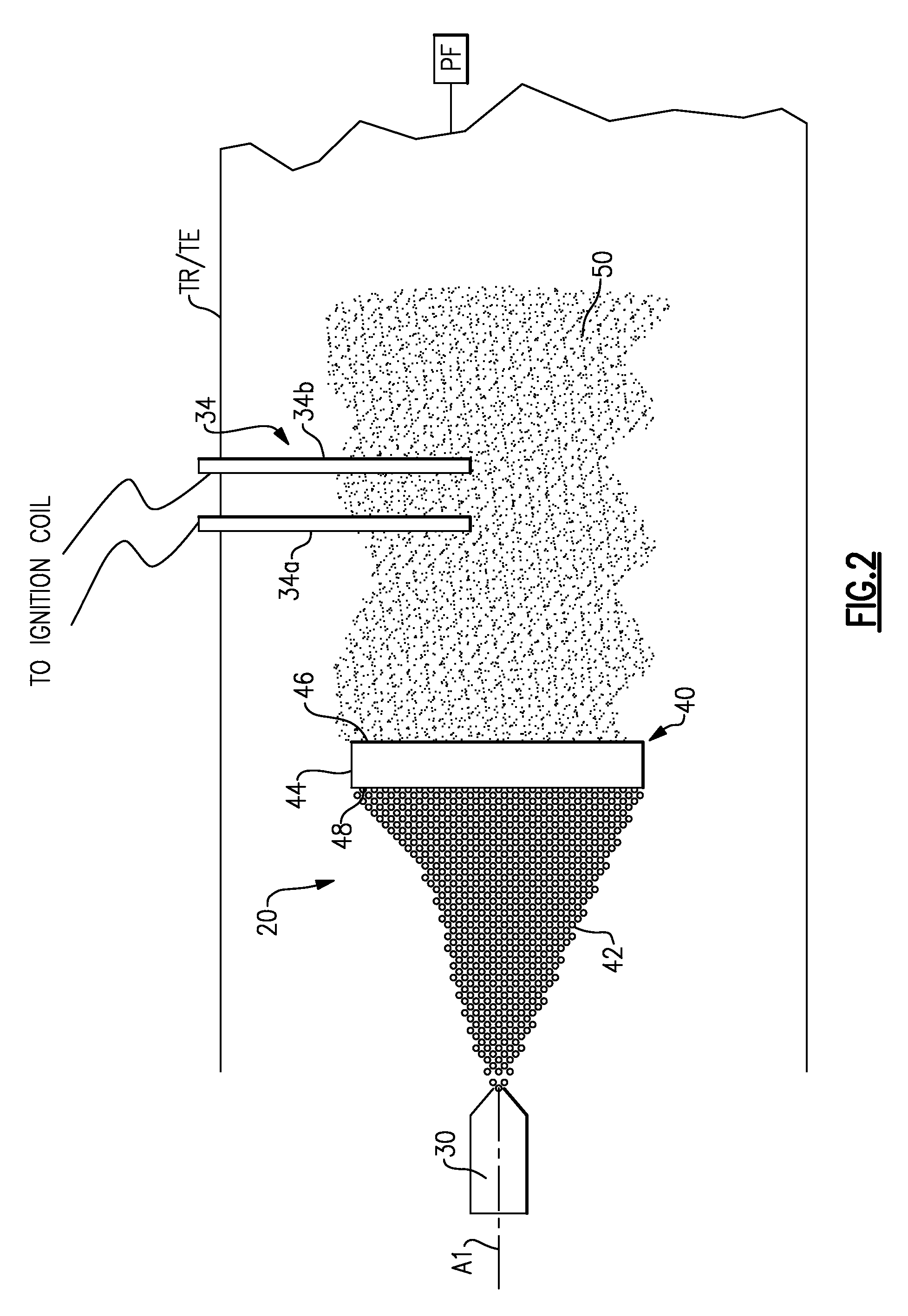

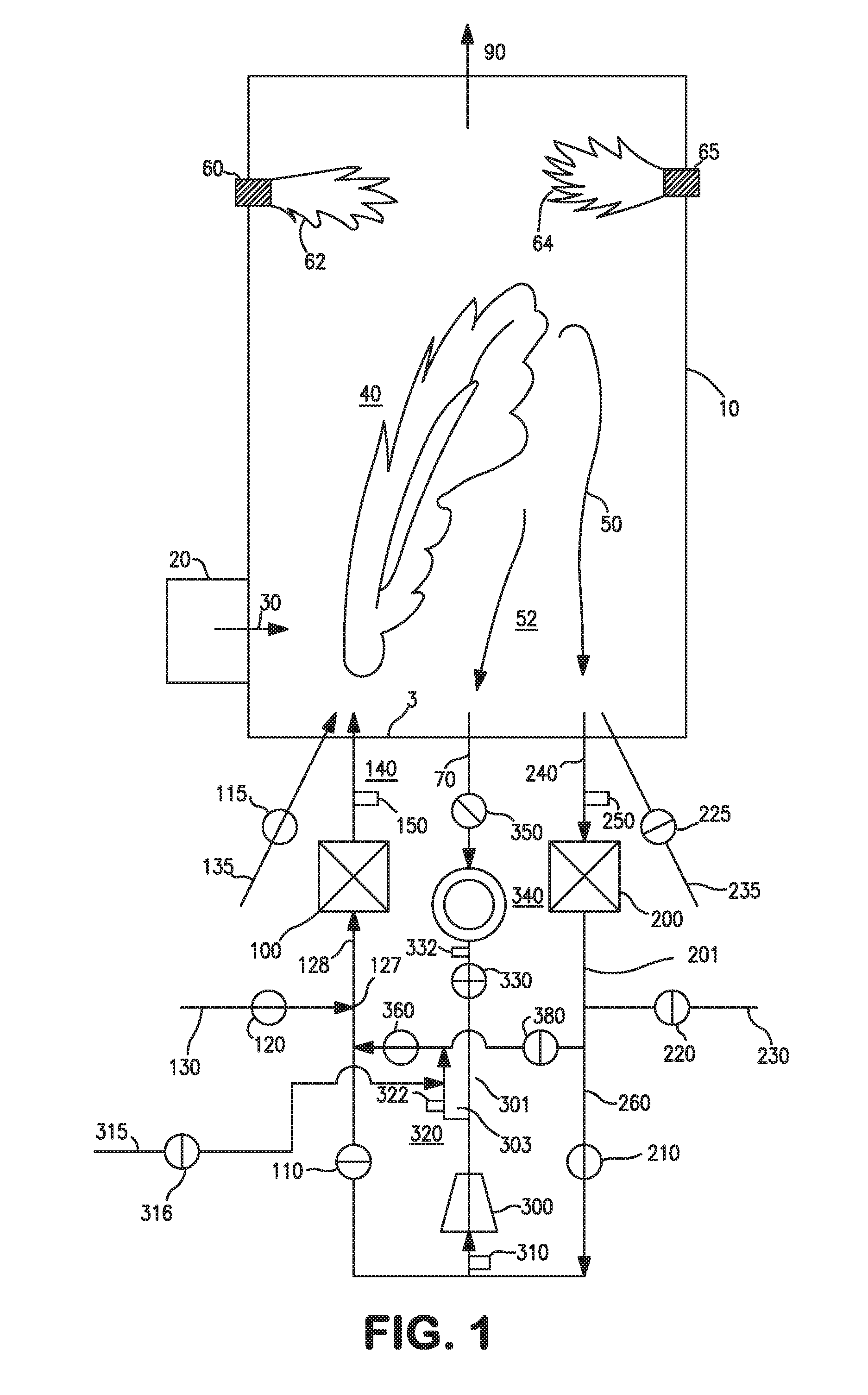

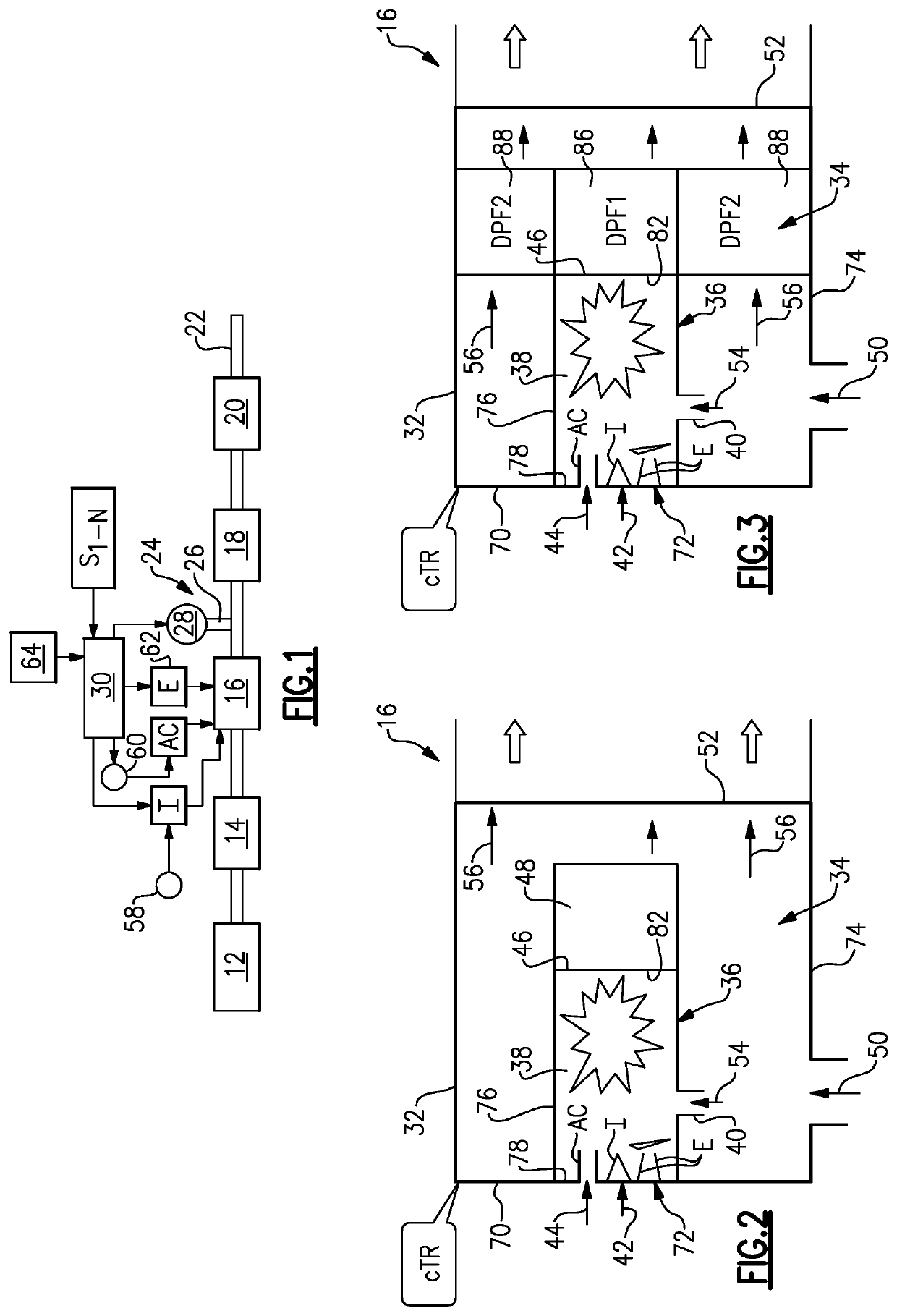

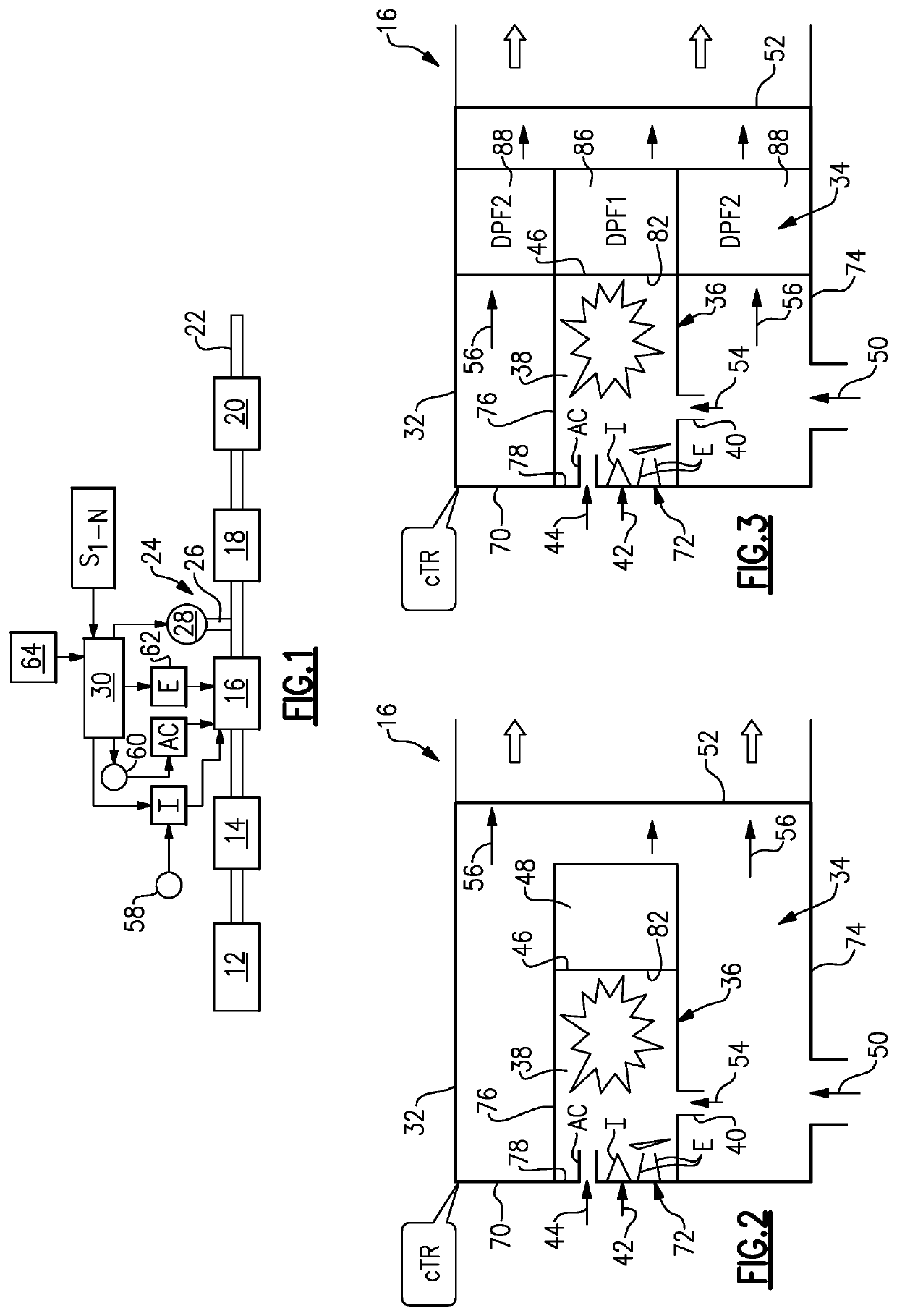

Airless thermal regenerator or enhancer with mixer

InactiveUS20100319329A1Easy to igniteReducing fuel droplet sizeFlow mixersExhaust apparatusParticulatesCombustor

A combustor comprises a fuel-fired burner for a vehicle application. In one example, the fuel-fired burner is configured to regenerate a particulate filter where the fuel-fired burner comprises one of a thermal regenerator or thermal enhancer that operates with airless fuel injection. A fuel nozzle supplies fuel to the fuel-fired burner and an igniter ignites fuel sprayed from the fuel nozzle. A mixer is positioned downstream of the fuel nozzle and upstream of the igniter and operates to reduce fuel droplet size, which improves ignition.

Owner:EMCON TECHNOLOGIES

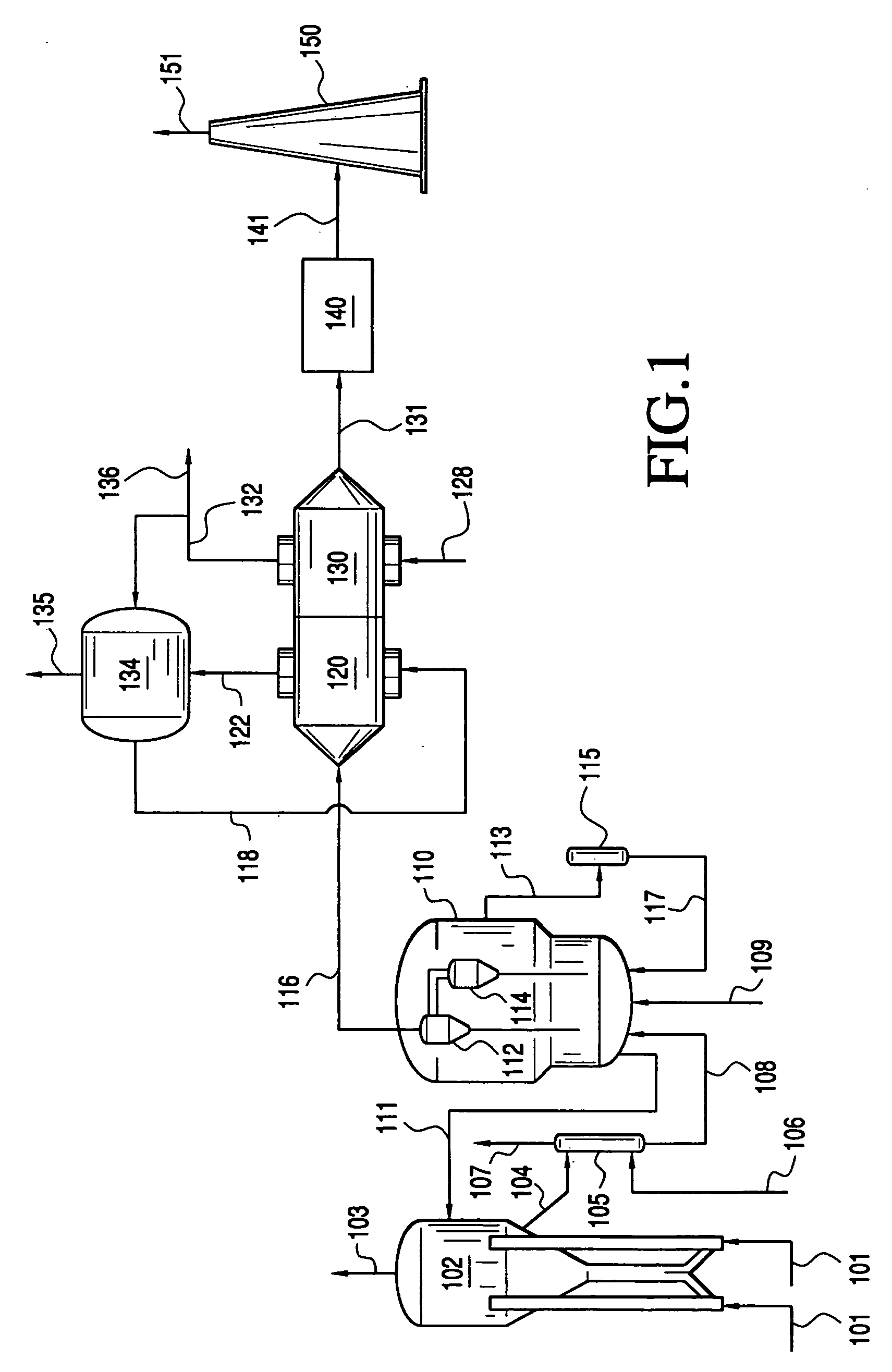

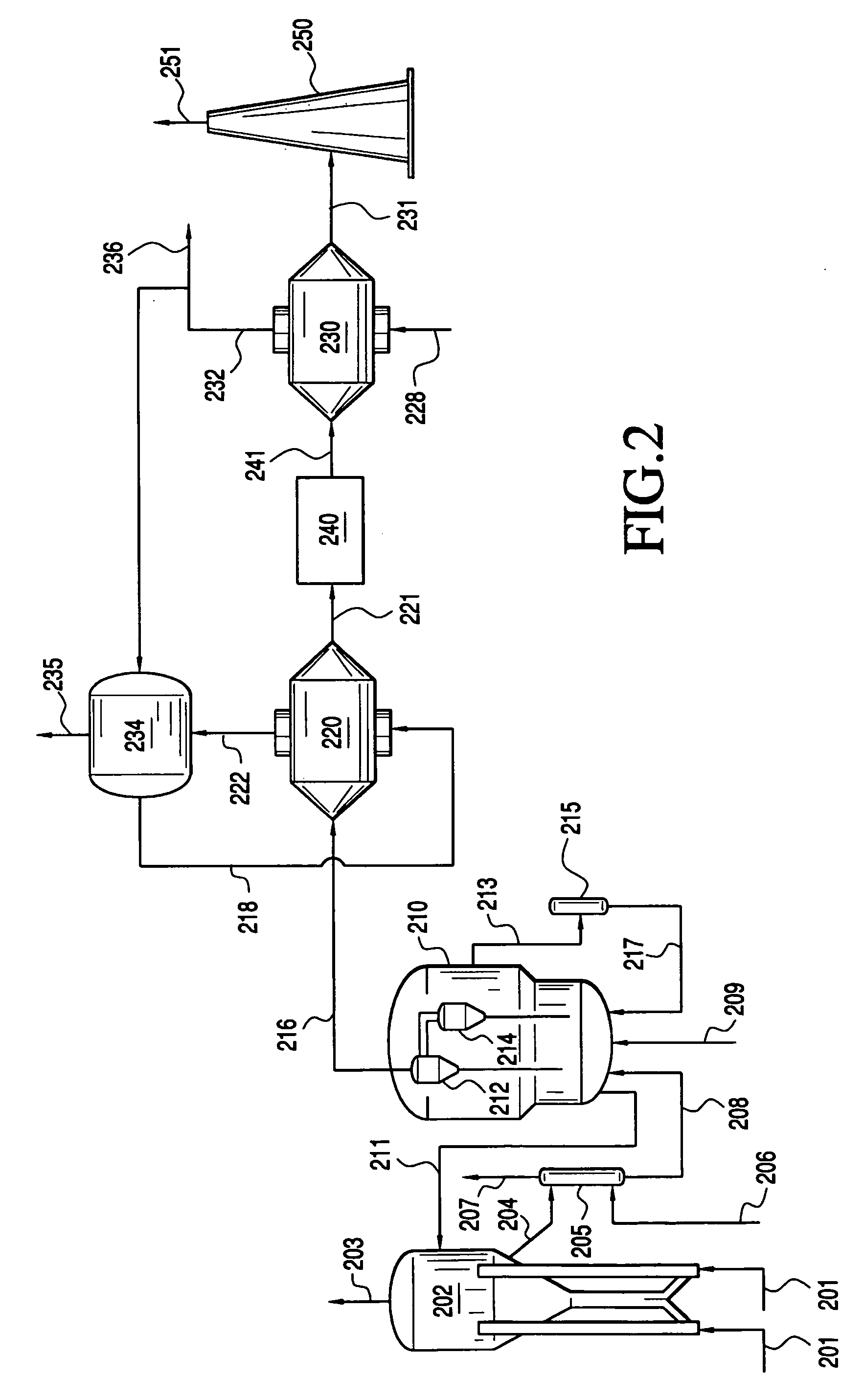

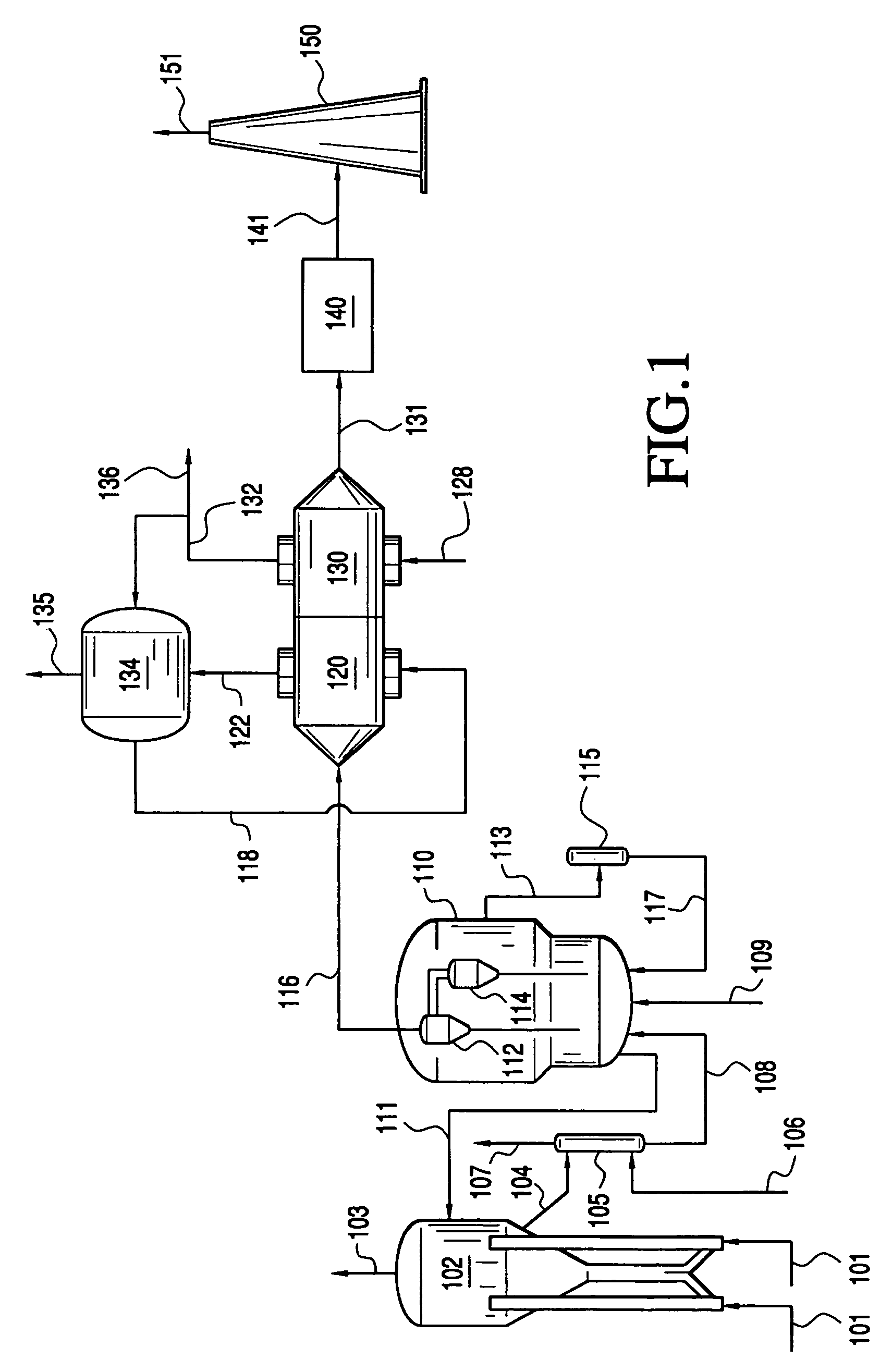

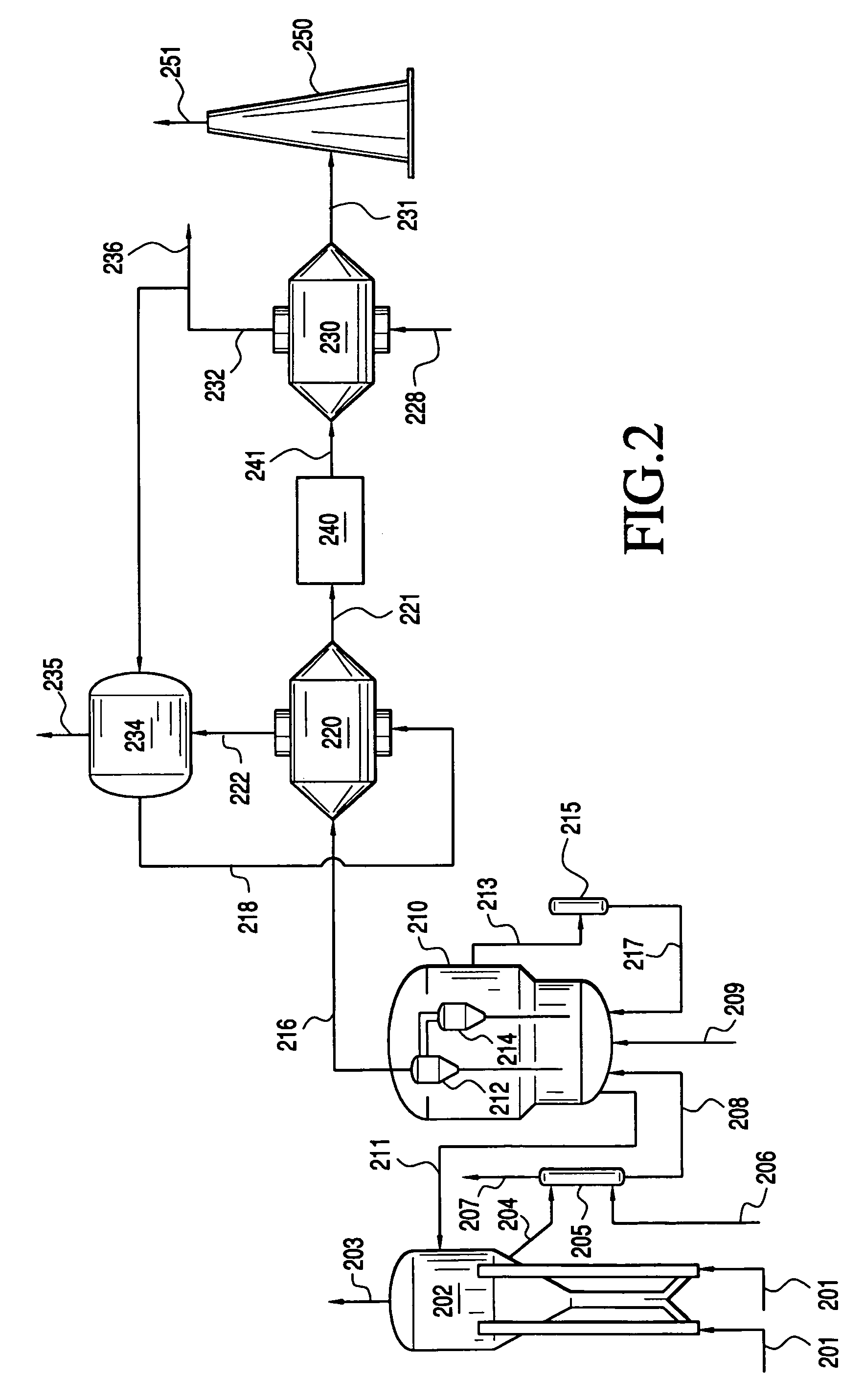

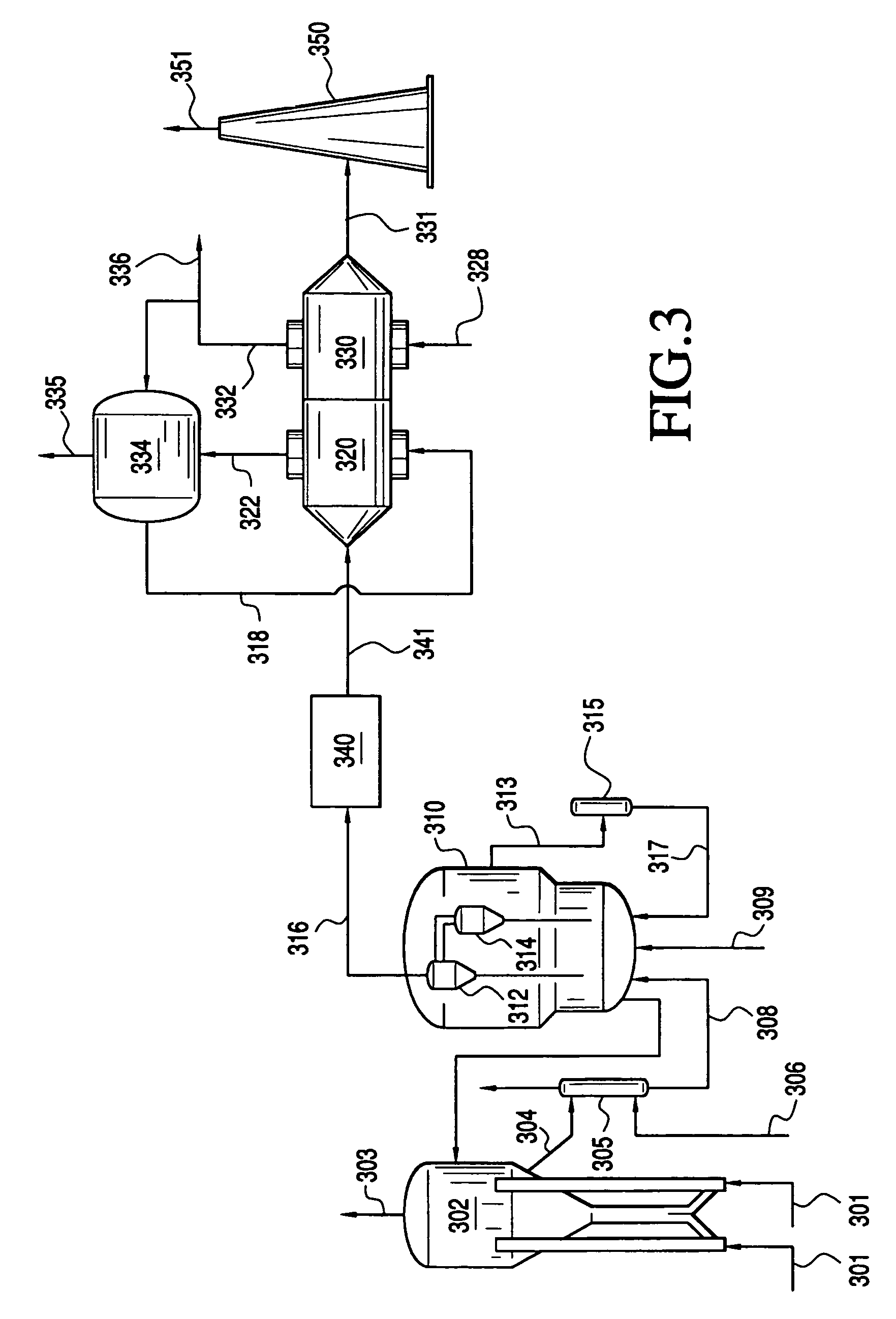

Heat recovery technique for catalyst regenerator flue gas

ActiveUS7404891B2Effective recoveryIncrease heightThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

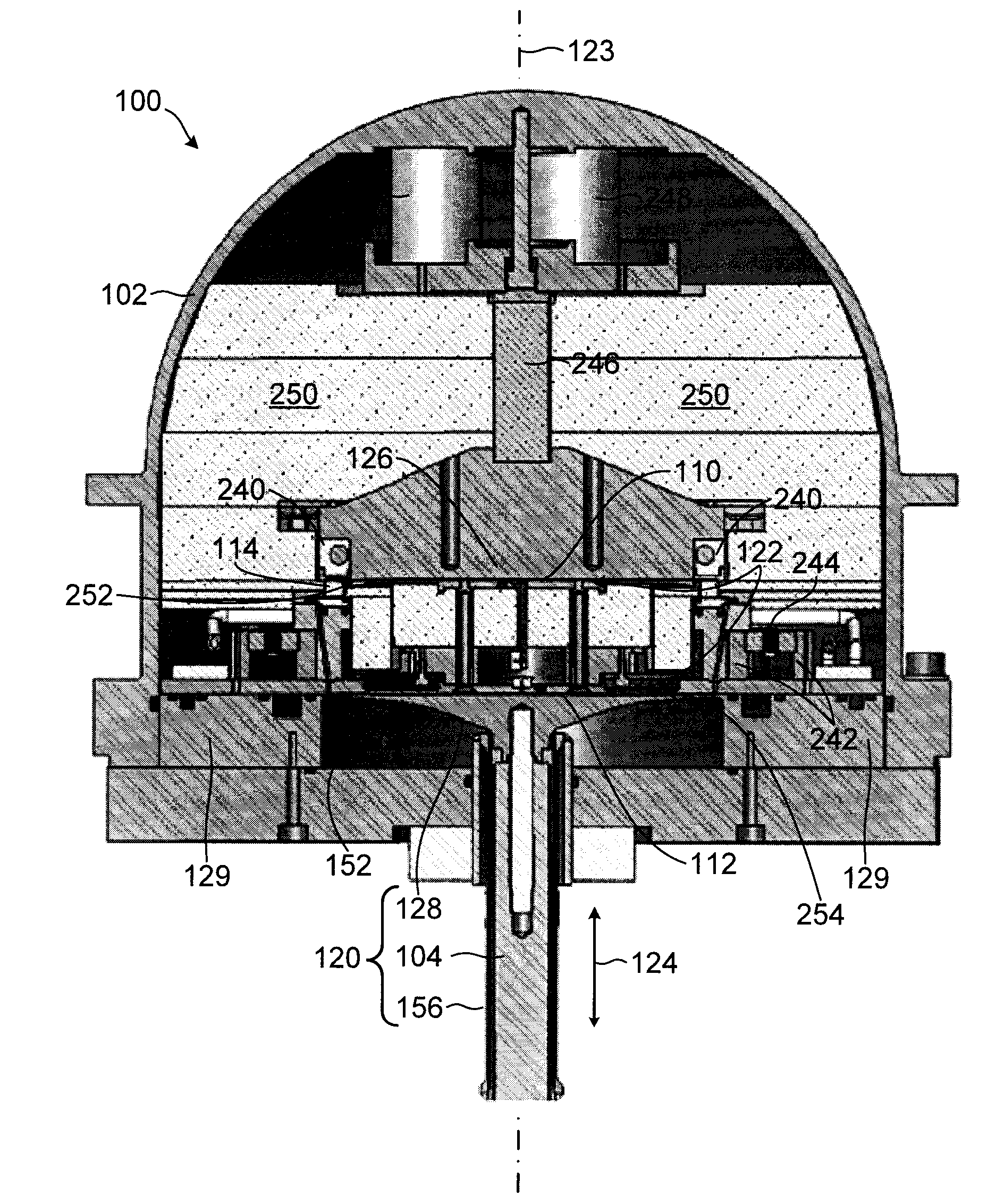

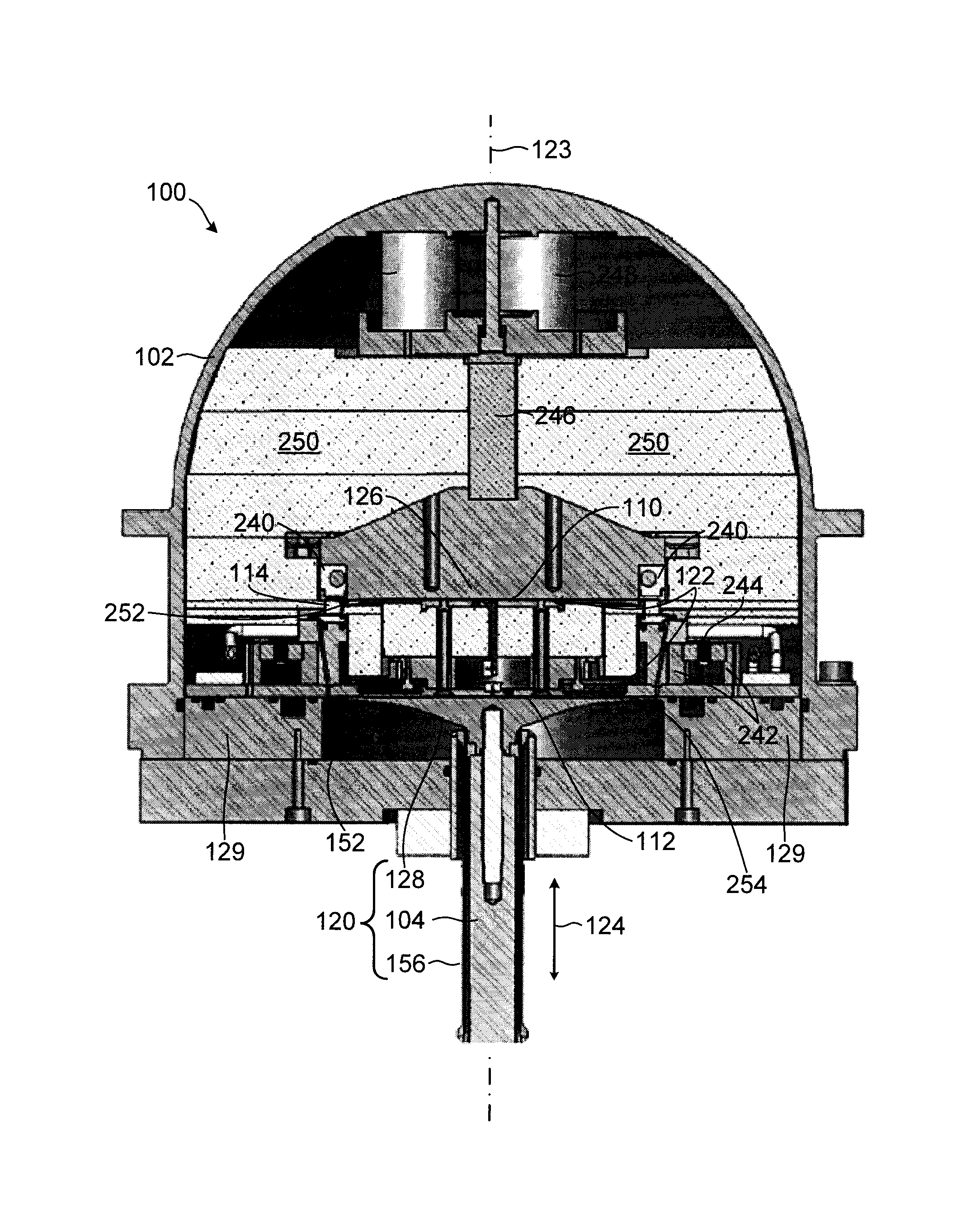

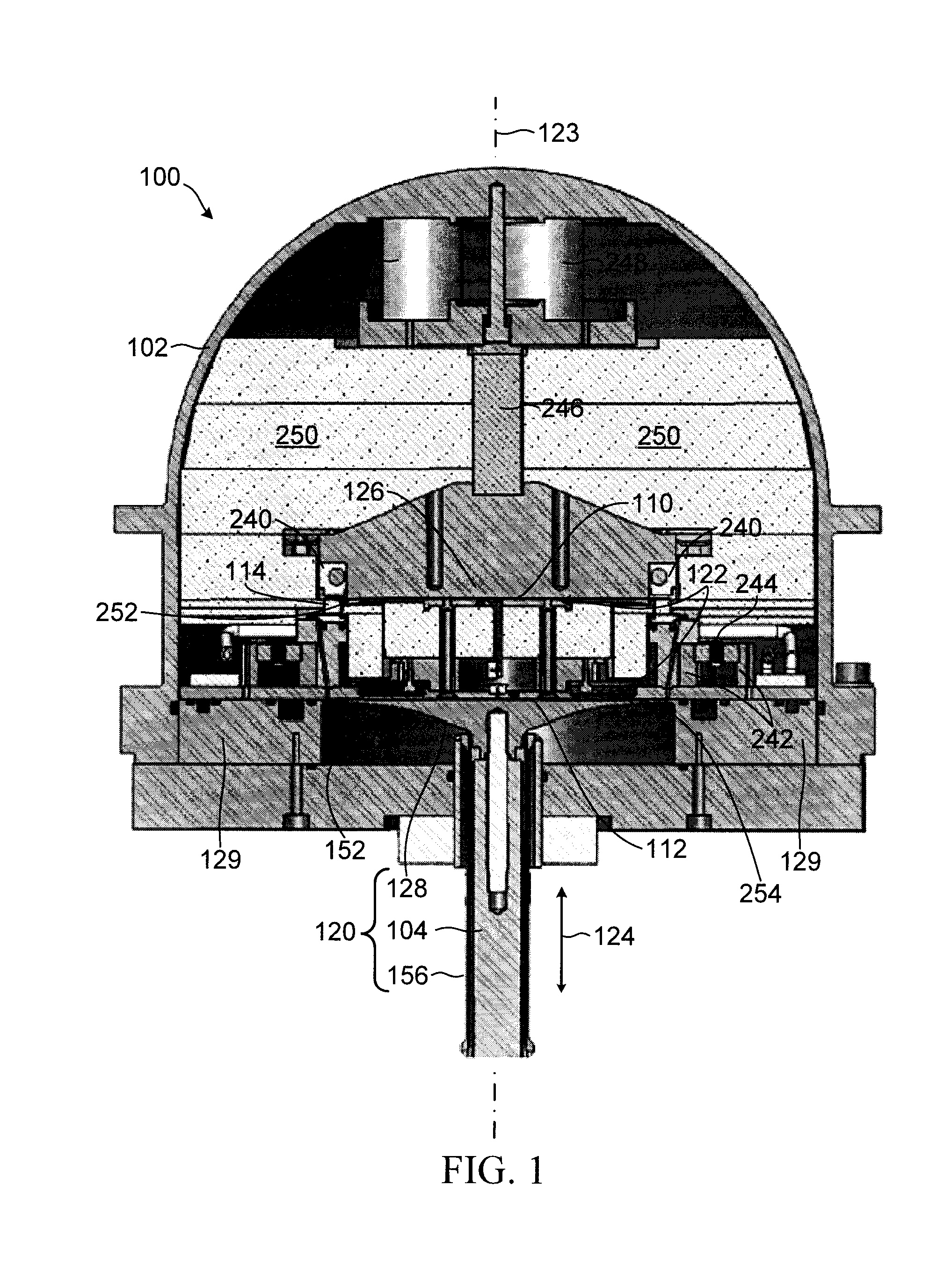

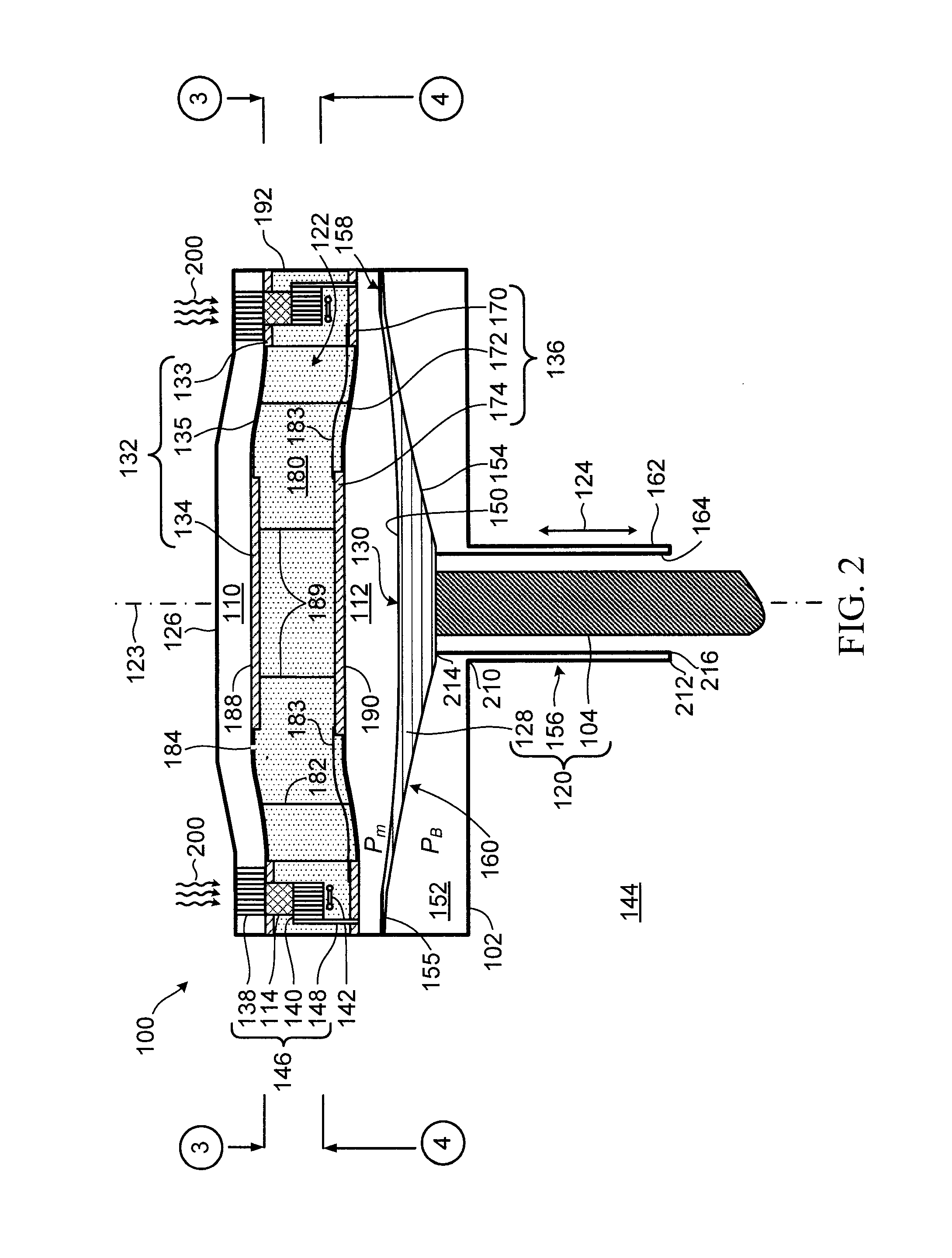

Stirling cycle transducer for converting between thermal energy and mechanical energy

ActiveUS20120159943A1Reduce mechanical stressStirling type enginesClosed-cycle gas positive displacement engine plantThermal energyReciprocating motion

The apparatus includes a housing, a compression chamber disposed in the housing and having at least a first interface operable to vary a volume of the compression chamber, an expansion chamber disposed in the housing and having a second interface operable to vary a volume of at least the expansion chamber, and a thermal regenerator in fluid communication with each of the compression chamber and the expansion chamber. The thermal regenerator is operable to alternatively receive thermal energy from gas flowing in a first direction through the regenerator and to deliver the thermal energy to gas flowing in a direction opposite to the first direction through the regenerator. The compression chamber, the expansion chamber, and the regenerator together define a working volume for containing a pressurized working gas. Each of the first and second interfaces are configured for reciprocating motion in a direction aligned with a transducer axis, the reciprocating motion being operable to cause a periodic exchange of working gas between the expansion and the compression chambers. In one aspect, at least one of the first and second interfaces includes a resilient diaphragm, and a cylindrical tube spring coupled between the diaphragm and the housing, the tube spring being configured to elastically deform in a direction generally aligned with the transducer axis in response to forces imparted on the tube spring by the diaphragm to cause the at least one of the first and second interfaces to have a desired natural frequency. In another aspect the apparatus includes a first heat exchanger in communication with the expansion chamber, a second heat exchanger in communication with the compression chamber, the thermal regenerator is disposed between the first and second heat exchangers, and each of the first and second heat exchangers are peripherally disposed within the housing with respect to the transducer axis and configured to receive working gas flowing to or from the respective chambers and to redirect the working gas flow through the regenerator.

Owner:ETALIM

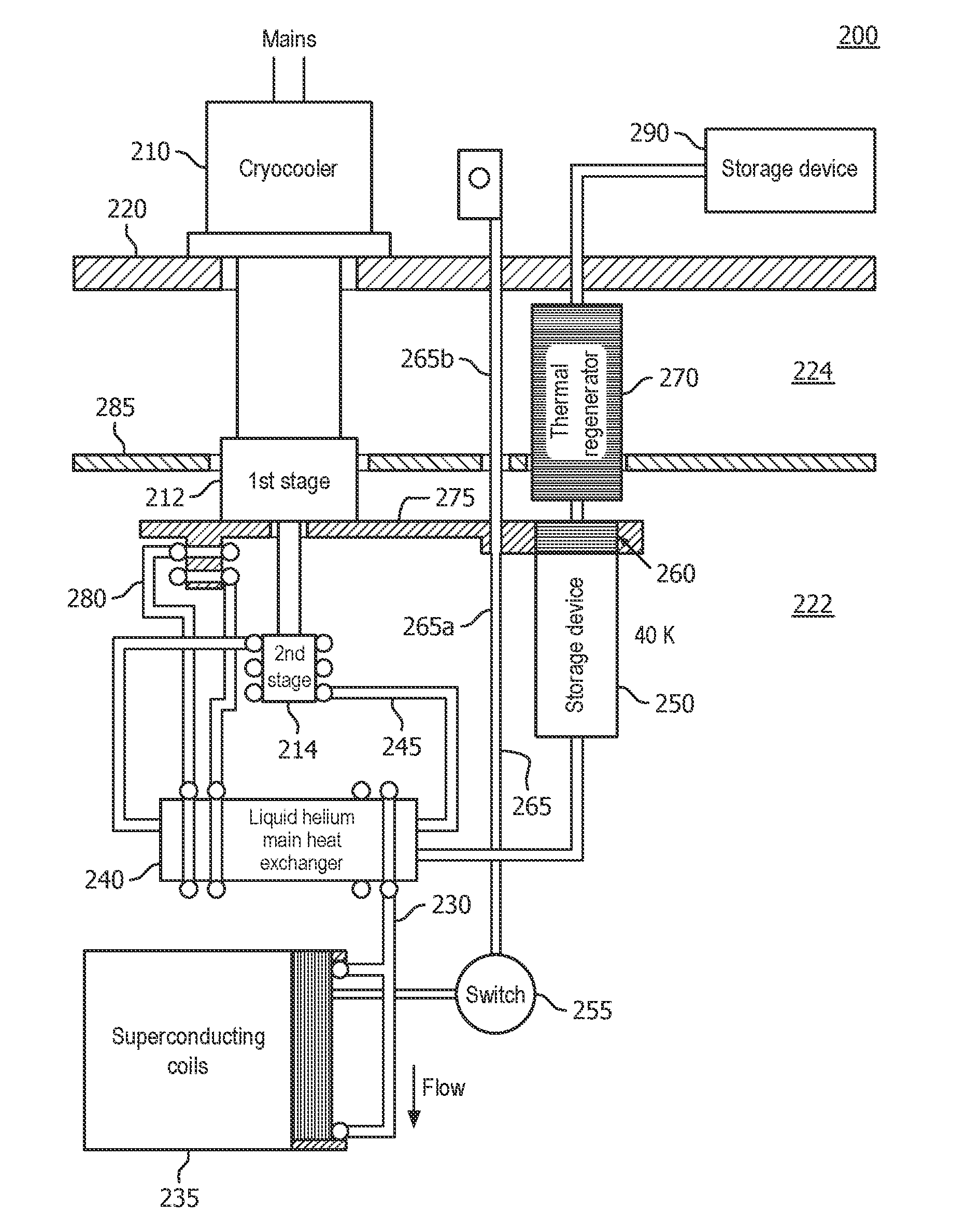

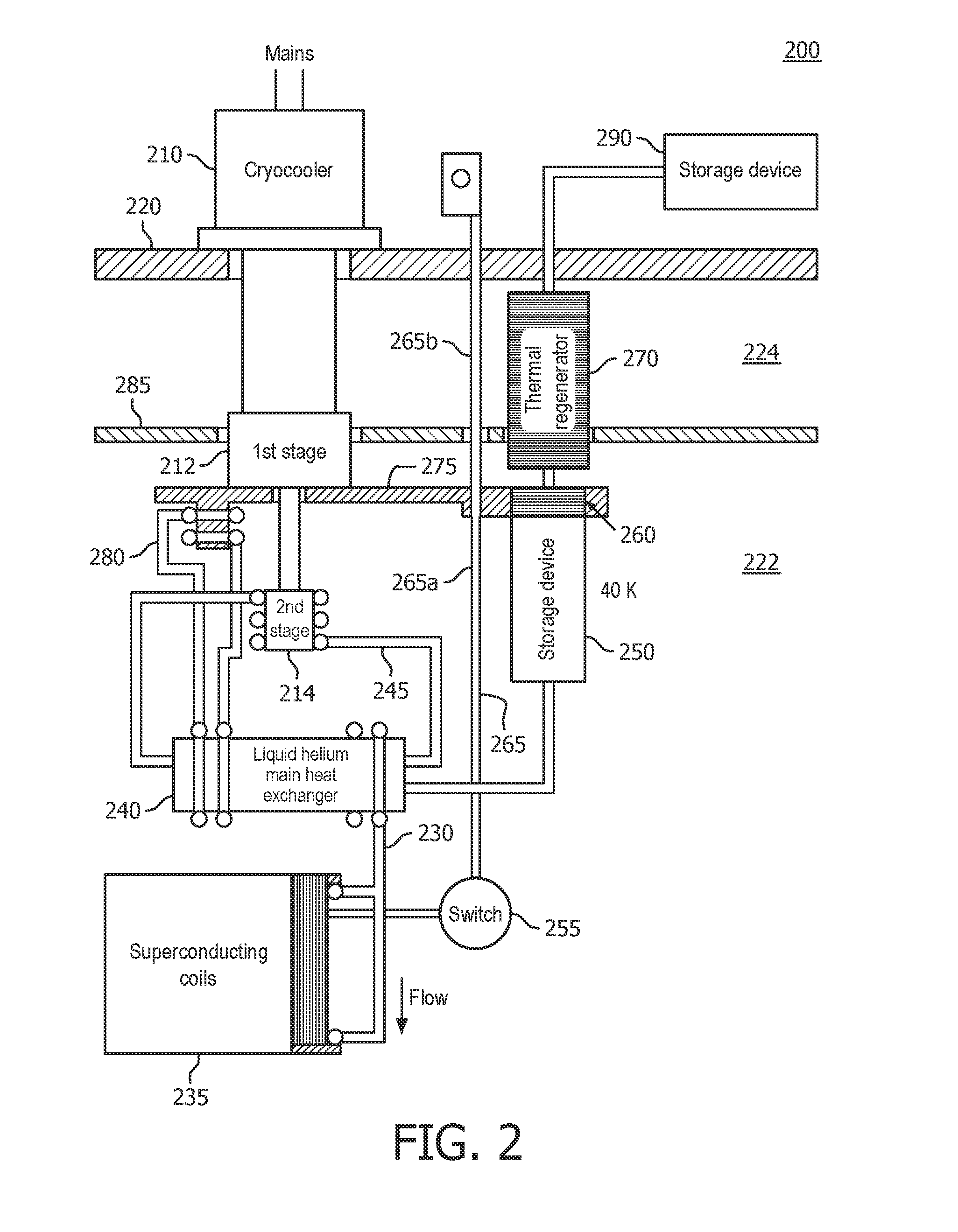

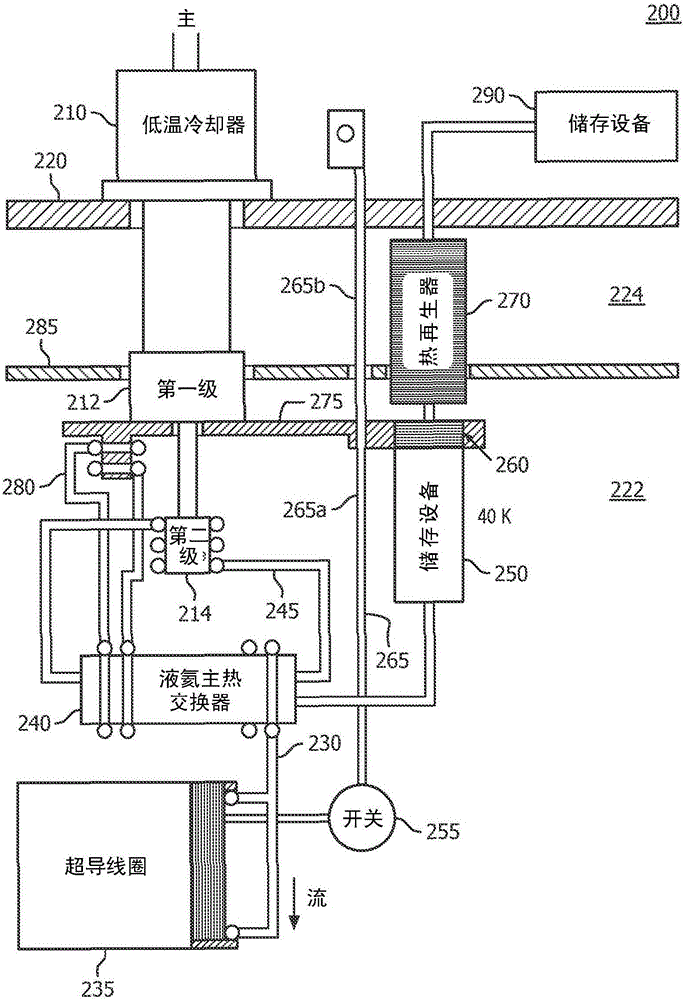

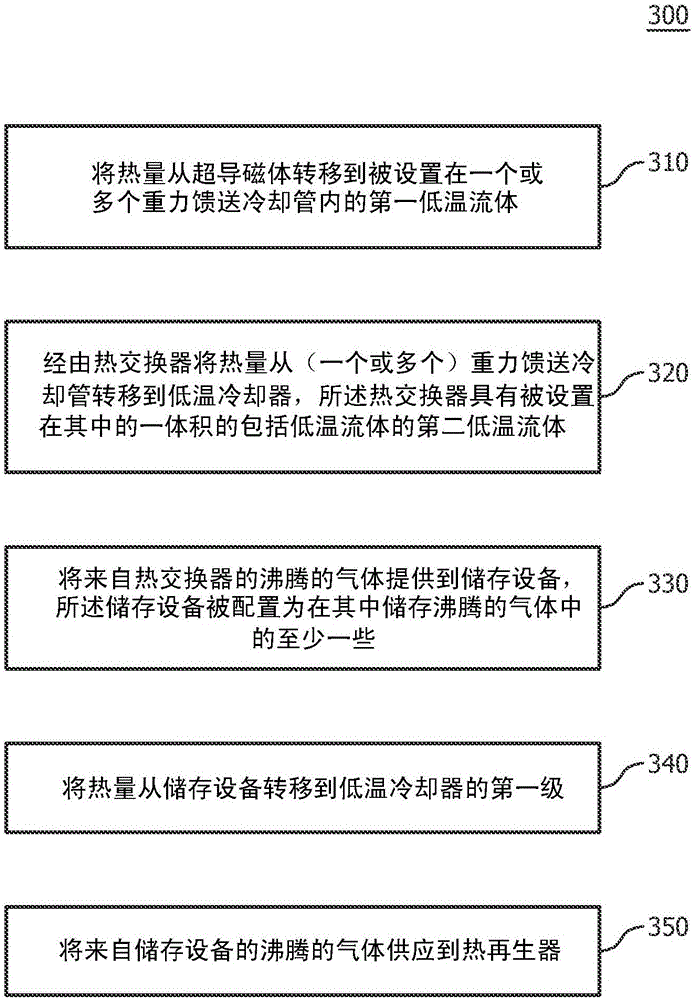

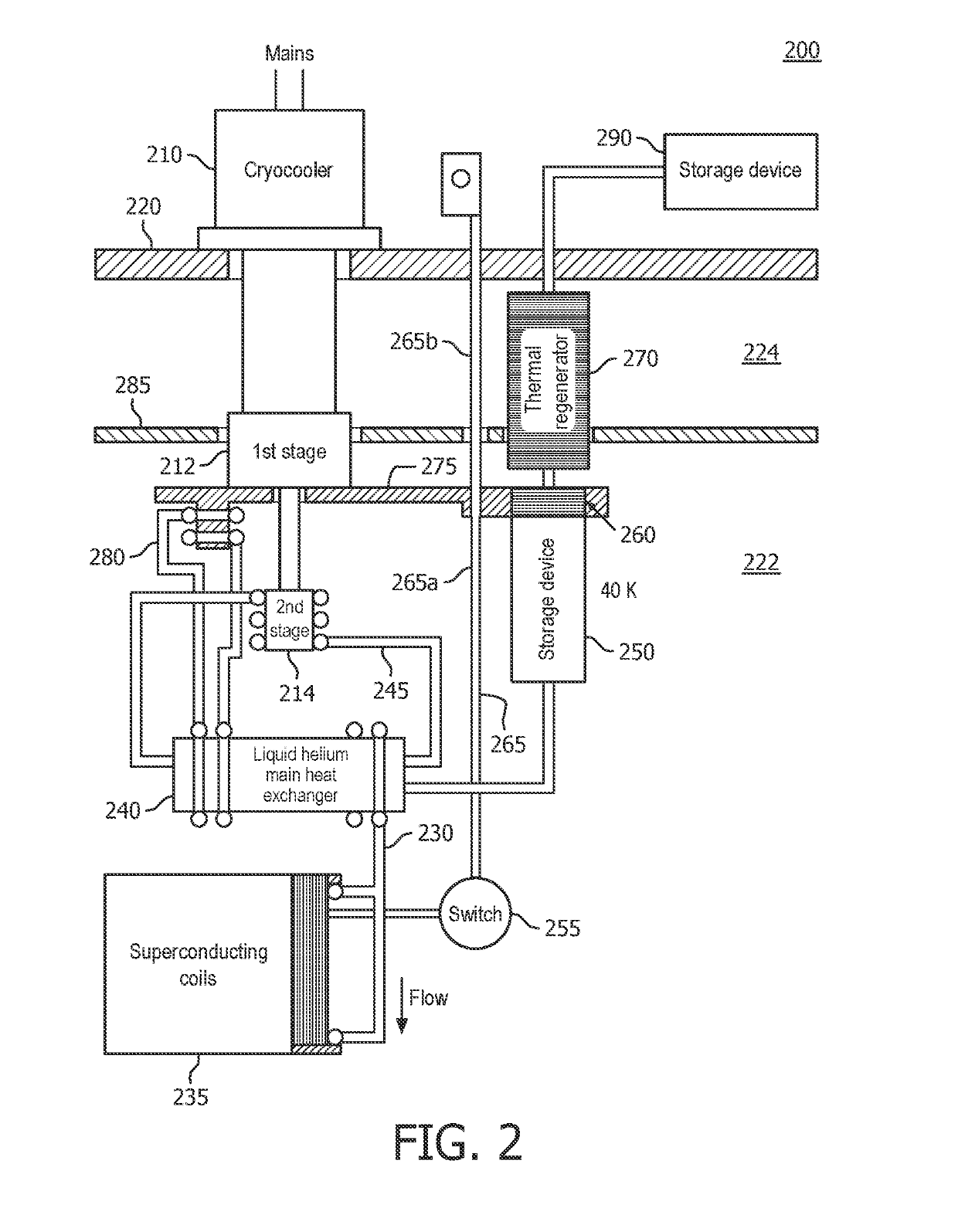

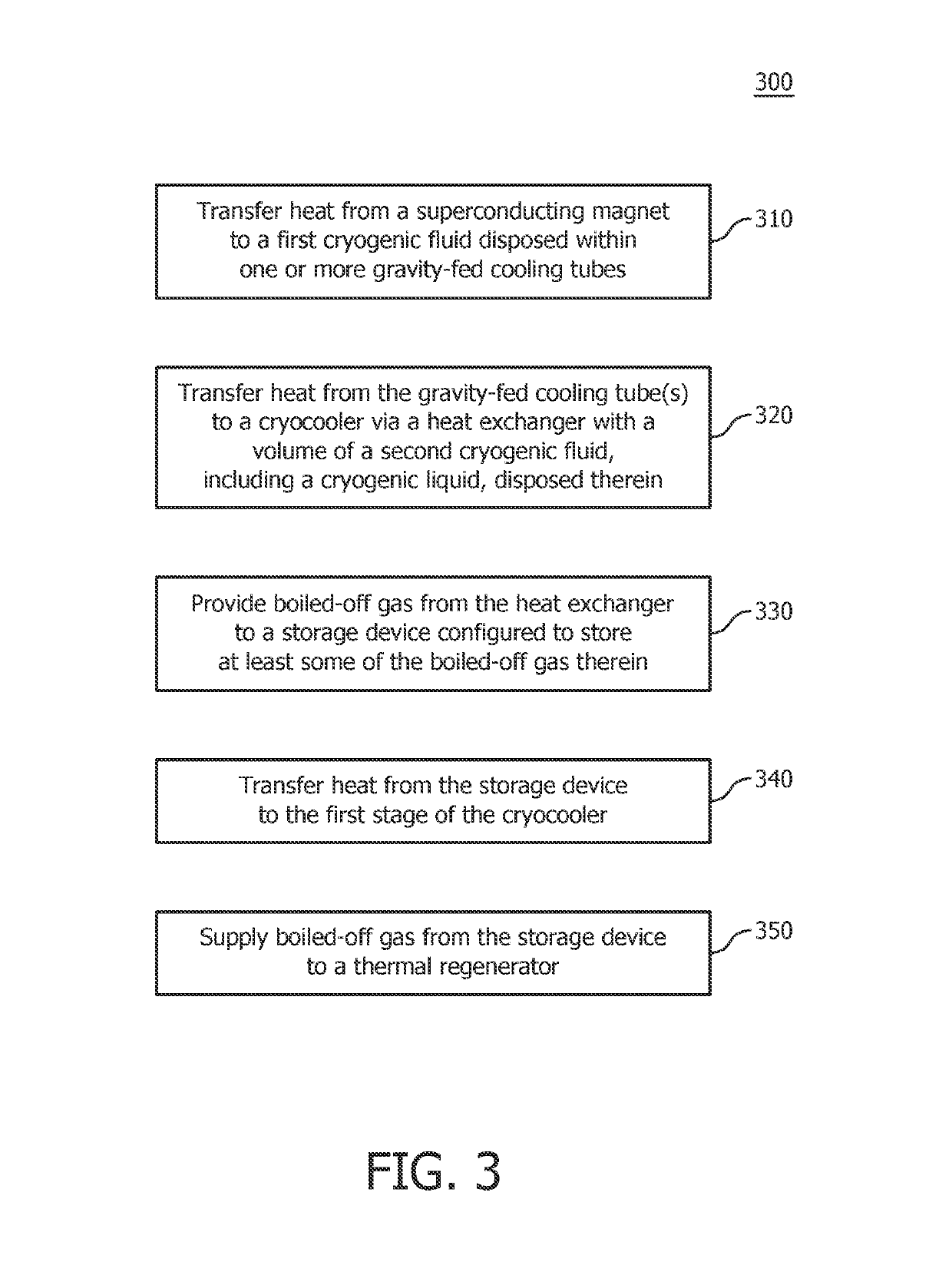

Superconducting magnet system inlcuding thermally efficient ride-through system and method of cooling superconducting magnet system

ActiveUS20160276082A1Magnetic measurementsCompression machinesSuperconducting CoilsProcess engineering

A superconducting magnet system, including a cryostat, and a ride-through system for the superconducting magnet system include: one or more gravity-fed cooling tubes configured to have therein a cryogenic fluid; a first heat exchanger configured to transfer heat from the one or more gravity-fed cooling tubes to a cryocooler; a storage device having an input connected to the first heat exchanger and configured to receive and store a boiled-off gas from the first heat exchanger; and a thermal regenerator having an input connected to the output of the storage device.

Owner:KONINKLJIJKE PHILIPS NV

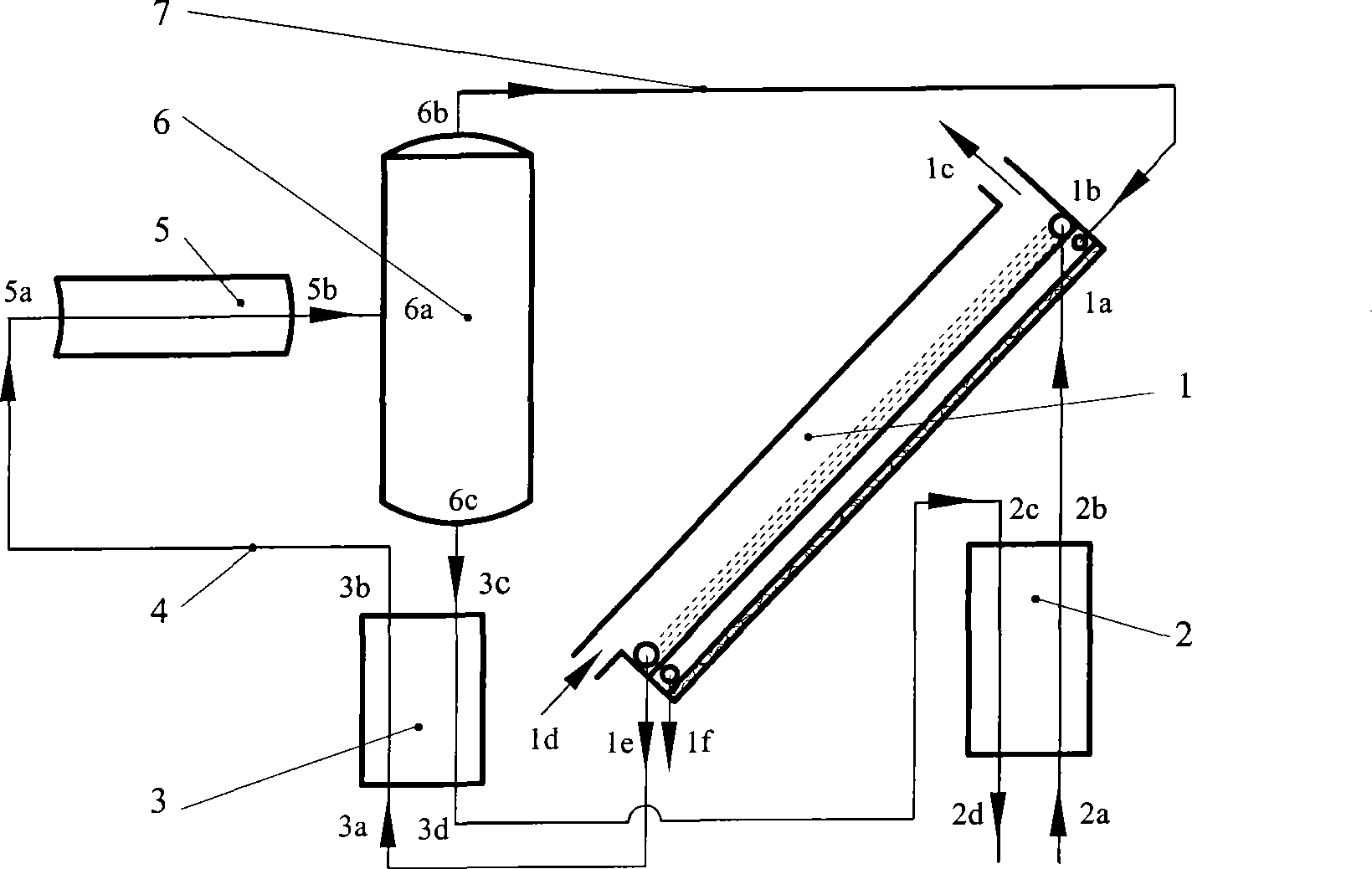

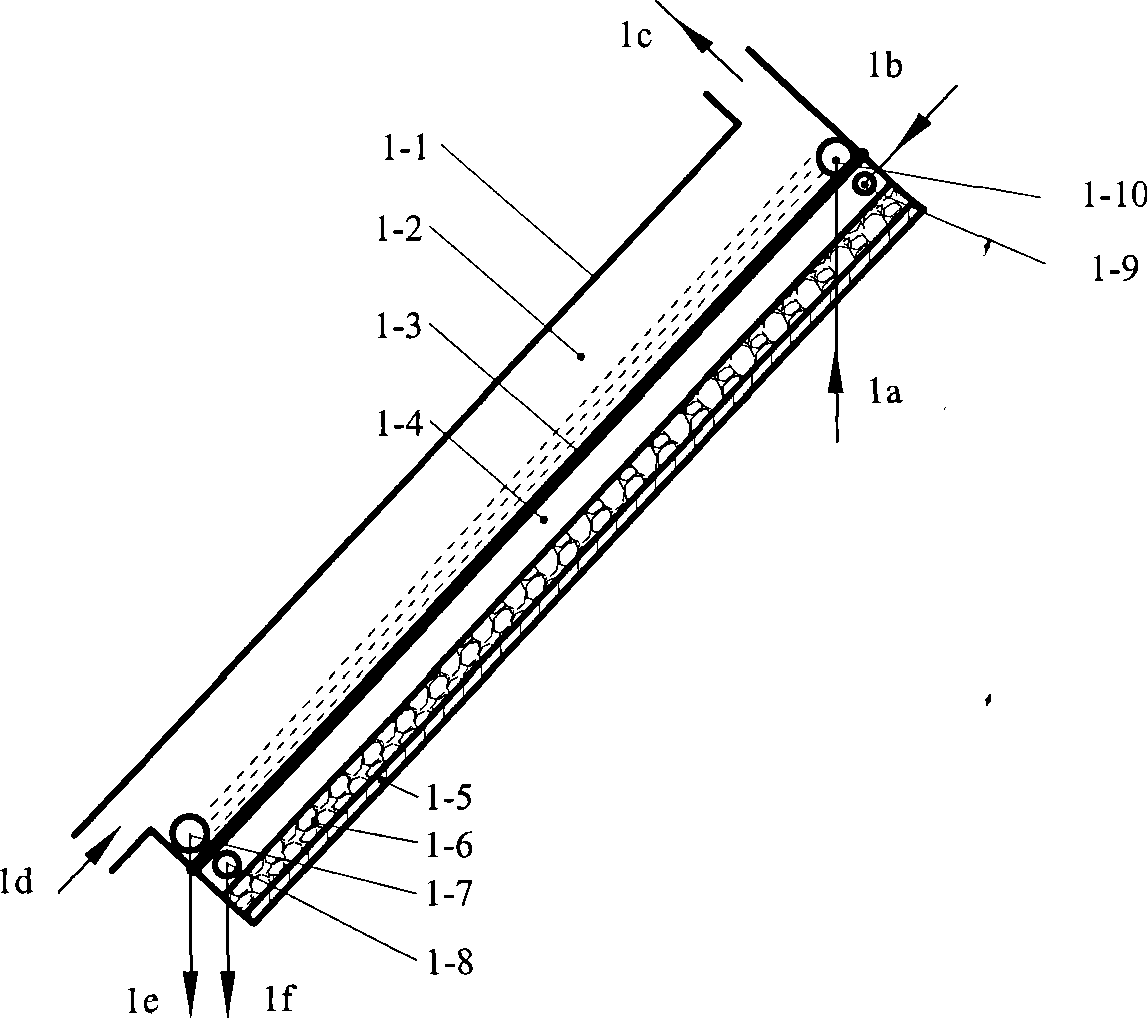

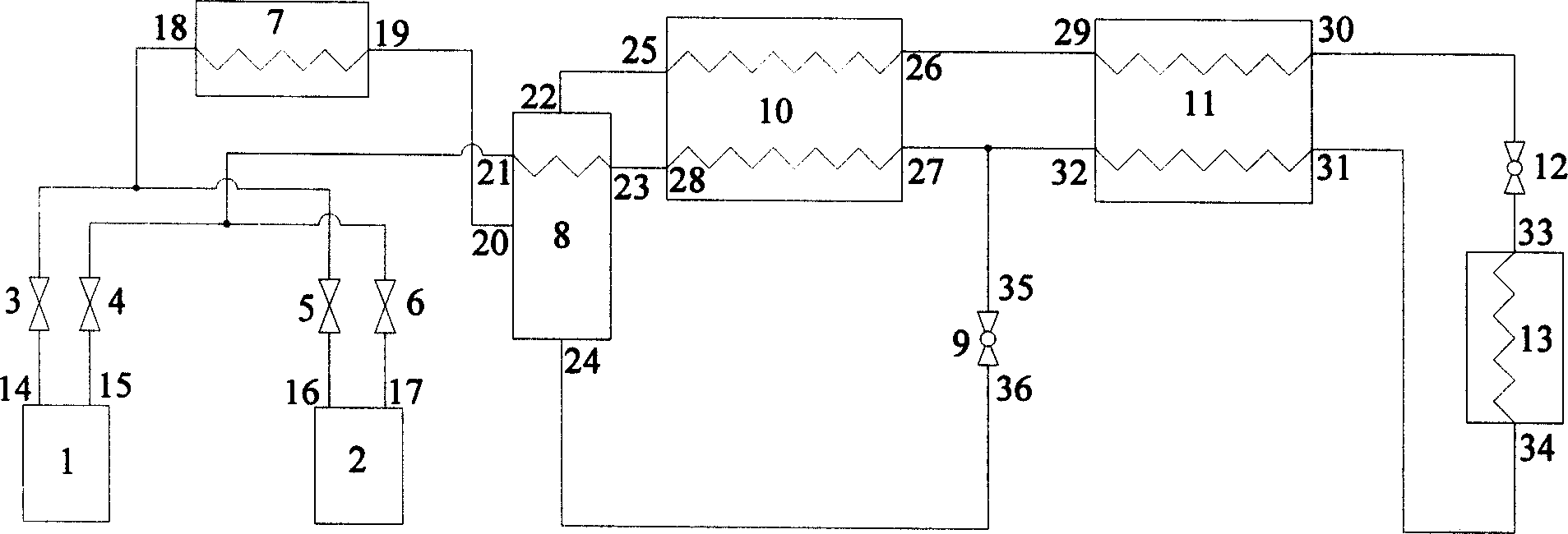

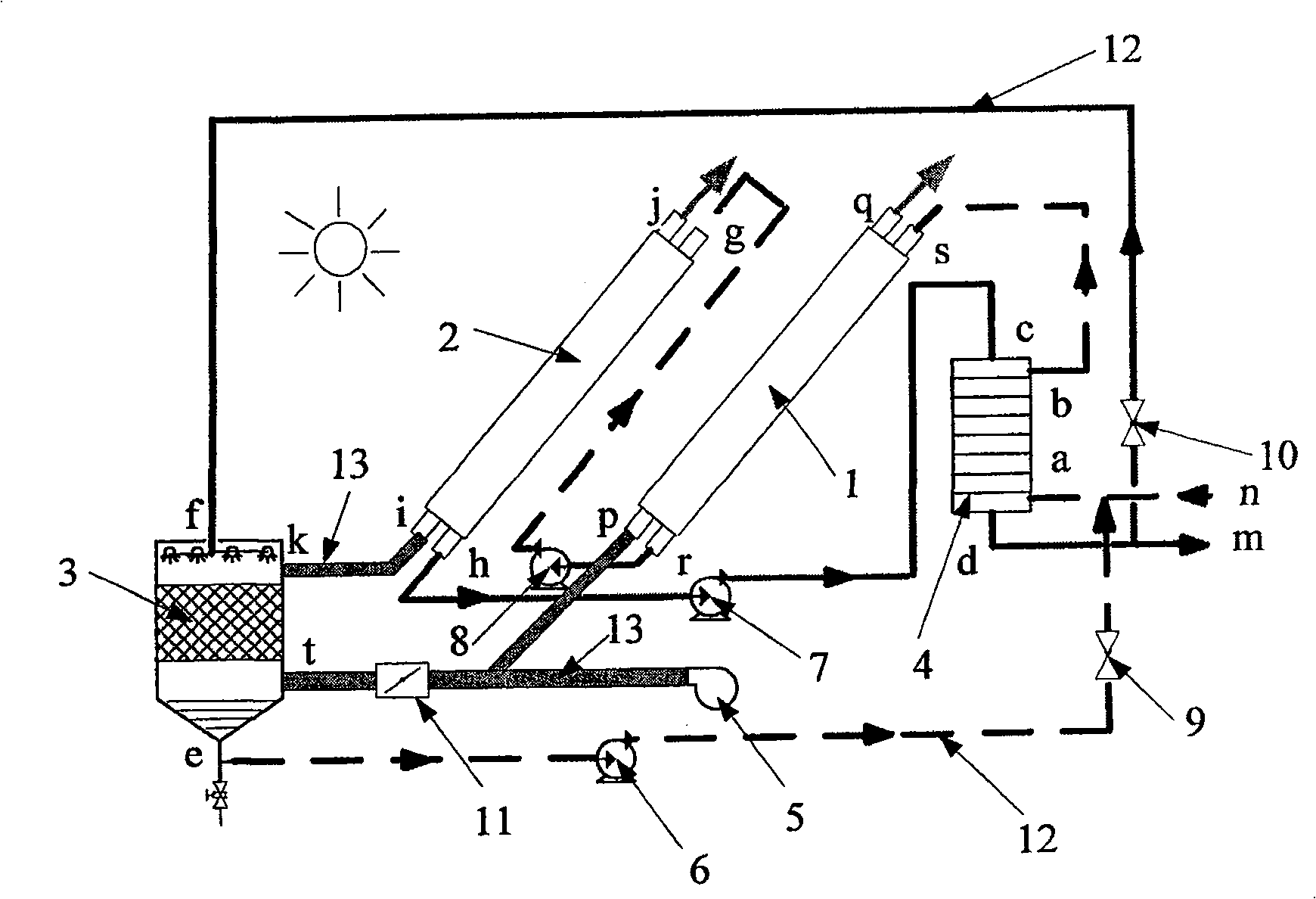

Solar groove type and flat-plate type combine heat-collecting solution regeneration method, device thereof and applications

InactiveCN101418972AIncrease regeneration concentrationRegeneration Concentration GuaranteeSolar heating energySolar heat devicesSteam condensationWater vapor

The invention provides a solar energy groove and flat-plate combined heat-collecting solution regeneration method, a device thereof and application thereof. The method comprises the following steps: a solution I from a dehumidifier is pre-heated in a low-temperature sleeve heat exchanger and then delivered to a flat-plate heat-collecting regenerator while absorbing heat from solar radiation and heat generated during condensation of steam from a steam-liquid separator, so as to be regenerated in a non-boiling mode to obtain a solution II; and the obtained solution II is delivered to a high-temperature sleeve heat exchanger to be heated further, delivered to a groove heat collector to be regenerated in a boiling mode and finally delivered to the steam-liquid separator to obtain a solution III and water vapor by separation. The device consists of the low-temperature sleeve heat exchanger, the flat-plate heat-collecting regenerator, the high-temperature sleeve heat exchanger, the groove heat collector and the steam-liquid separator which are arranged sequentially along a solution delivery direction. The device is applicable to air condition dehumidification, steam-liquid separation or condensation drying and other fields. The device and the method realize boiling and non-boiling solution regeneration, greatly improve solution regeneration rate, ensure the condensation of regenerated solutions and improve the use rate of solar energy.

Owner:DONGGUAN UNIV OF TECH +1

Device for atmosphere conditioning for testing combustion engines, and associated method and use

ActiveUS20160349147A1Facilitate heat exchangeEngine testingCombustion-air/fuel-air treatmentCombustionEngineering

The invention relates to an atmosphere conditioning device for testing engines, comprising an inflow conduit connected to an engine admission, an outflow conduit connected to the exhaust of the engine and expelling exhaust gases, a communication conduit which communicates the inflow conduit with the outflow conduit, a supercharging turbogenerator comprising a turbine in the inflow conduit, a bypass valve which diverts the air flow that circulates towards the turbine, a heat regenerator consisting of heat exchangers in the inflow and outflow conduits, connected by the same heat transfer fluid circuit, a bypass valve in the outflow conduit together with the heat exchanger thereof, a heat exchanger in the outflow conduit downstream from the heat regenerator, and a turbocompressor downstream from the heat exchanger.

Owner:UNIV POLITECNICA DE VALENCIA

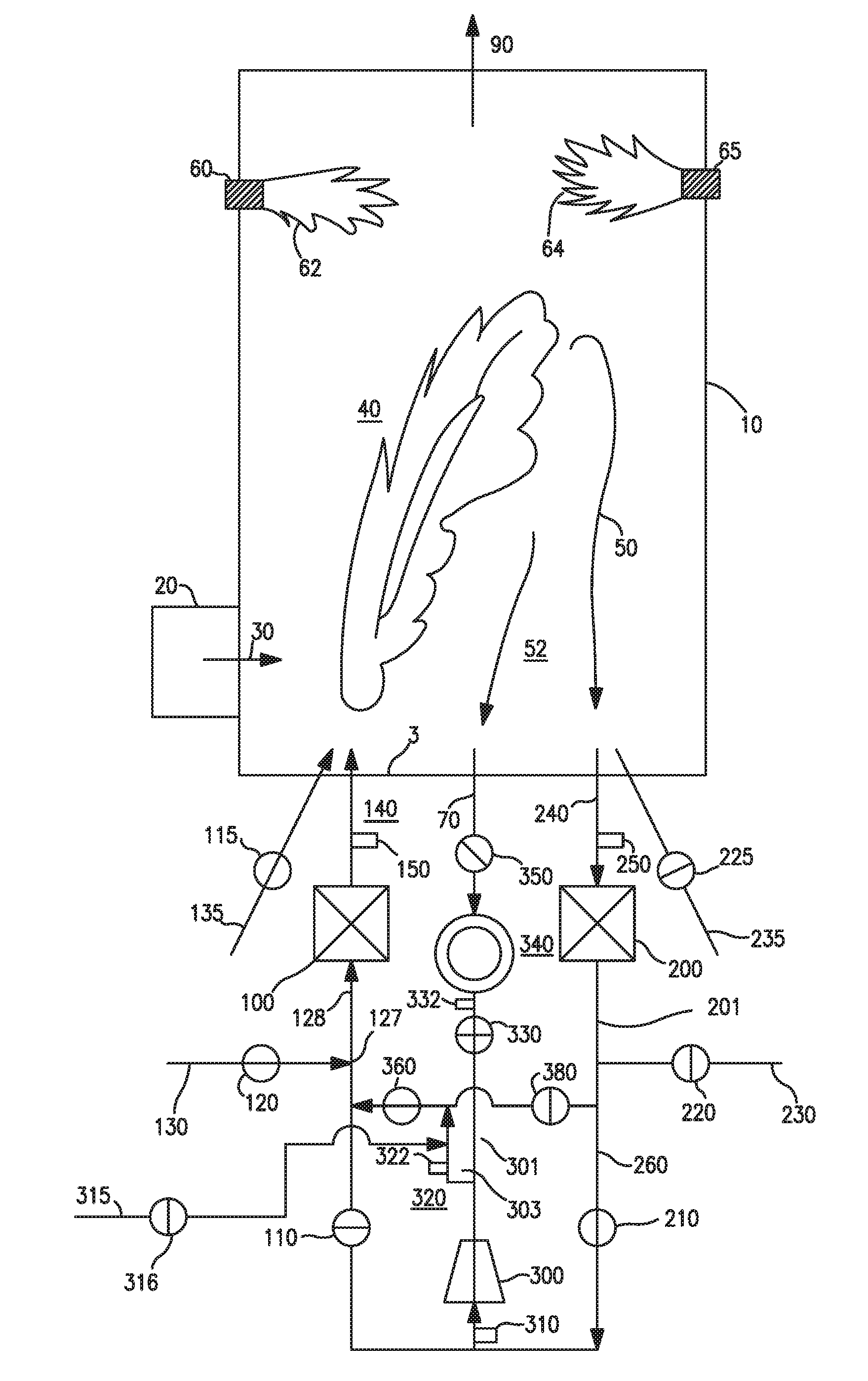

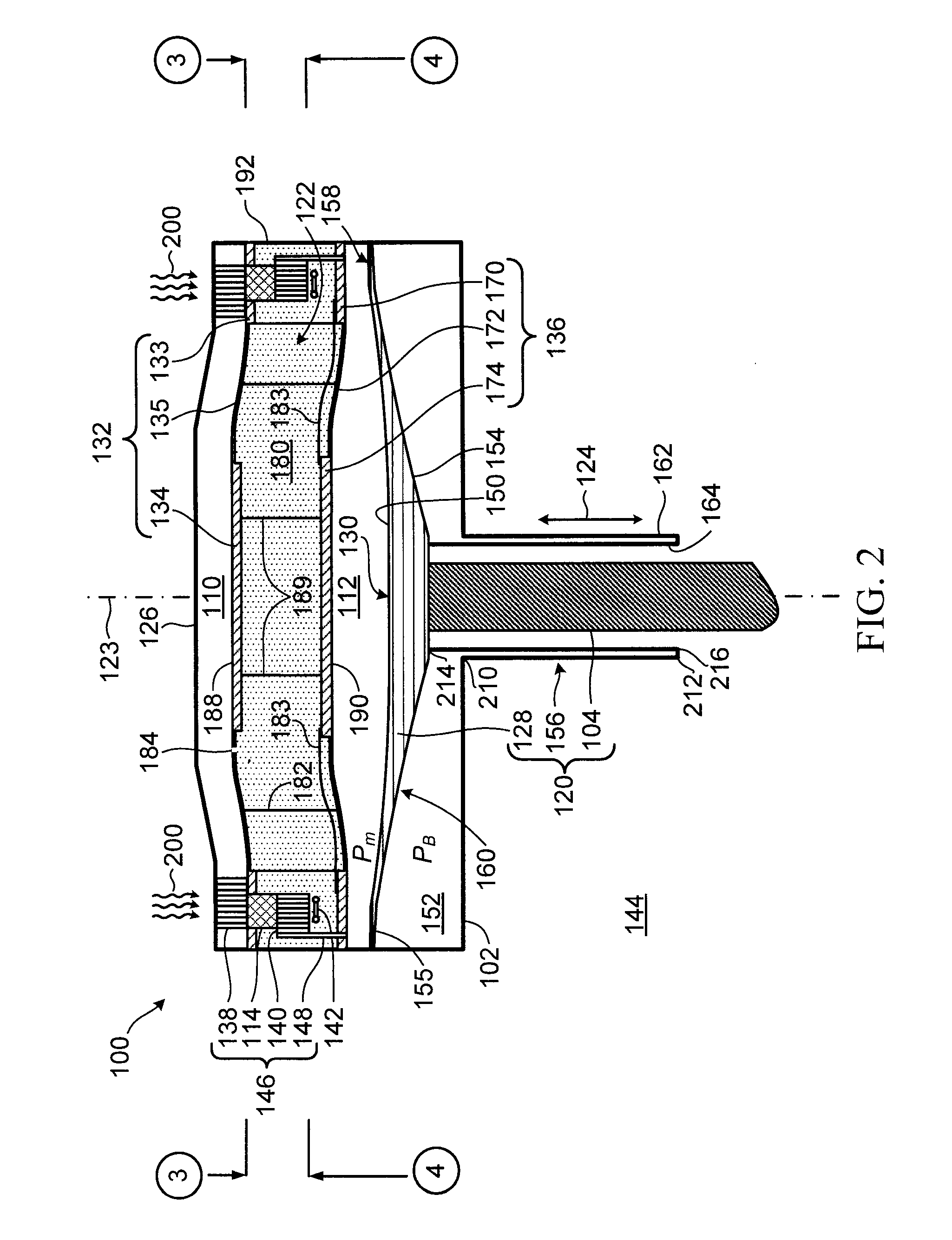

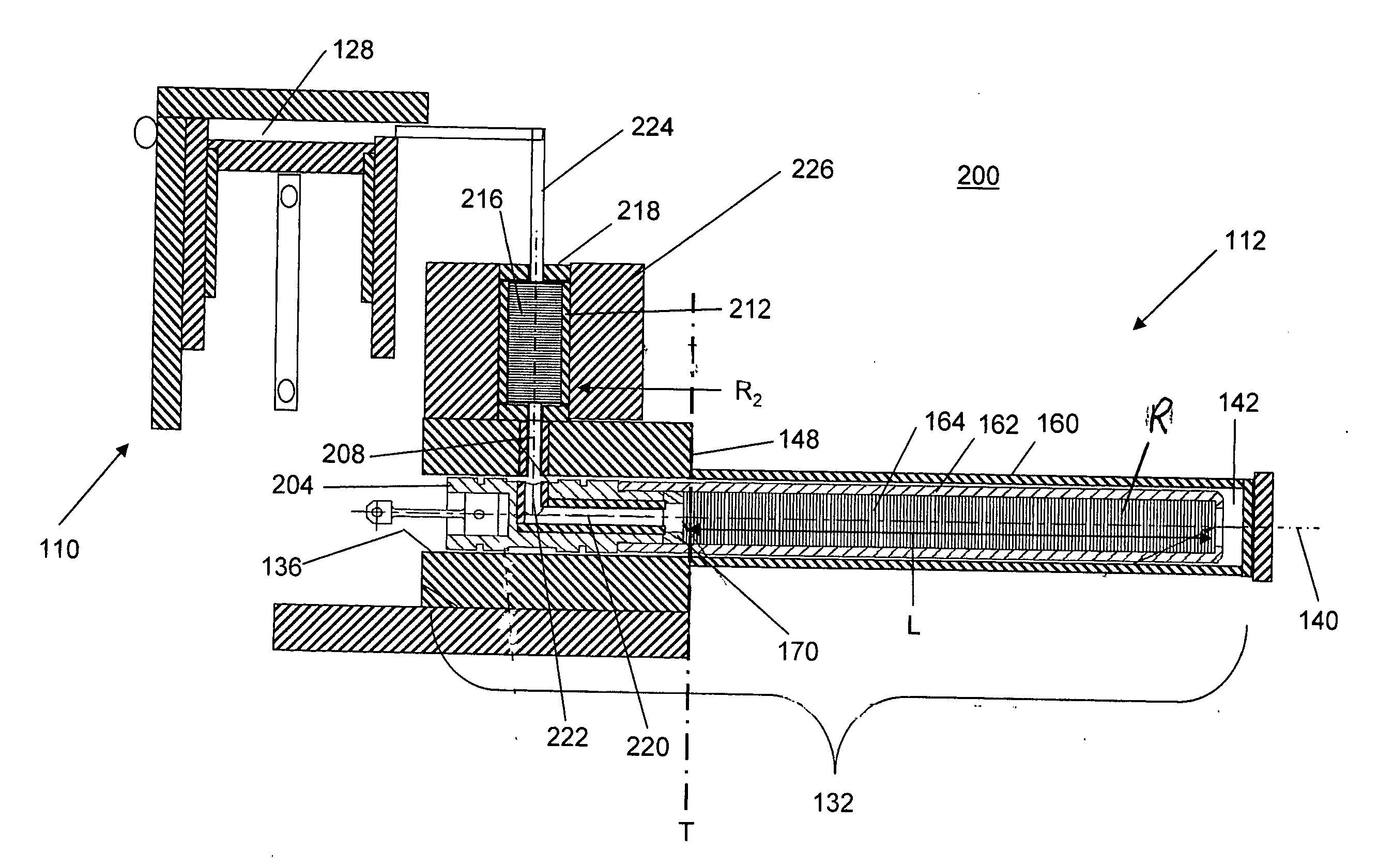

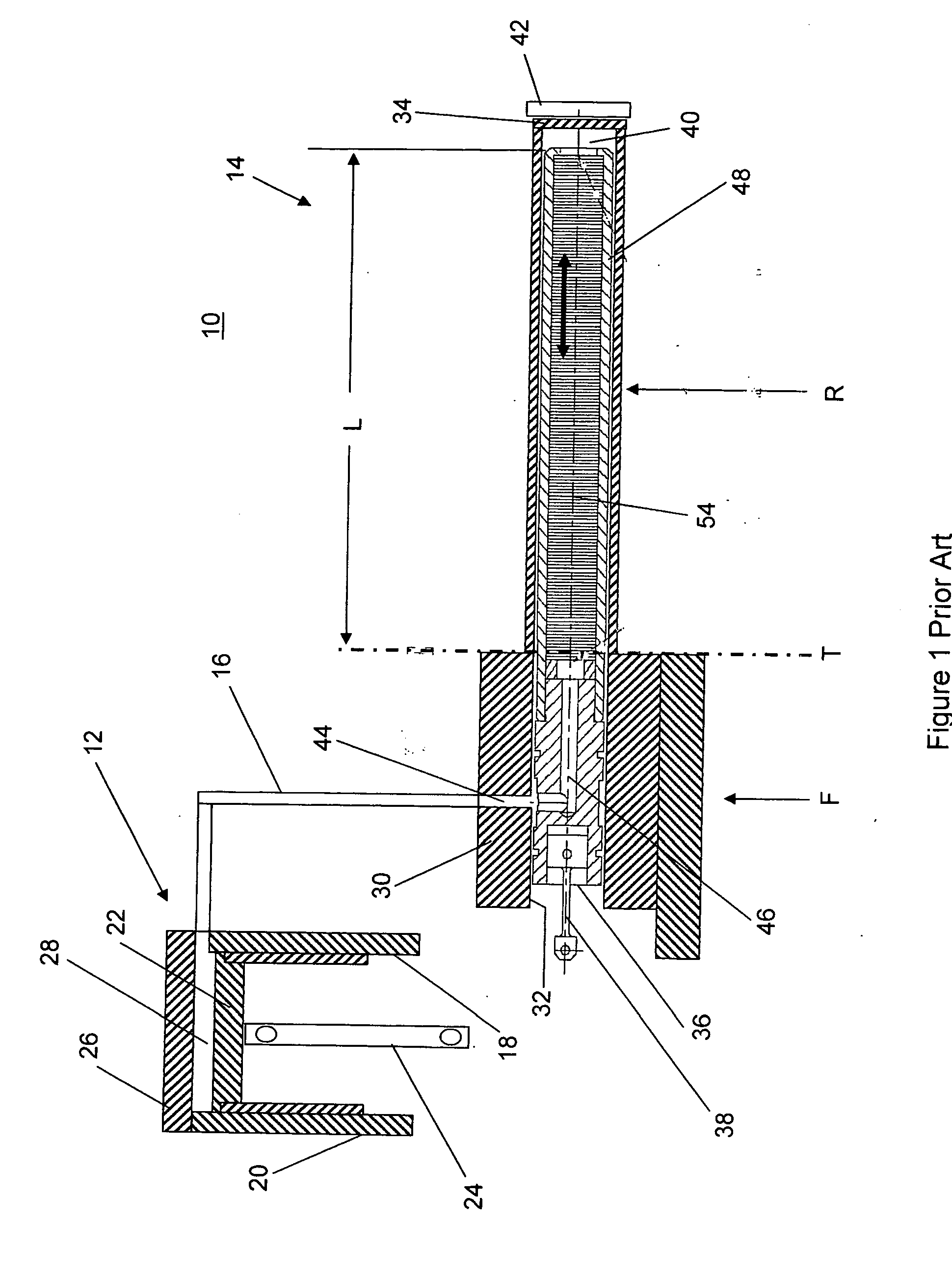

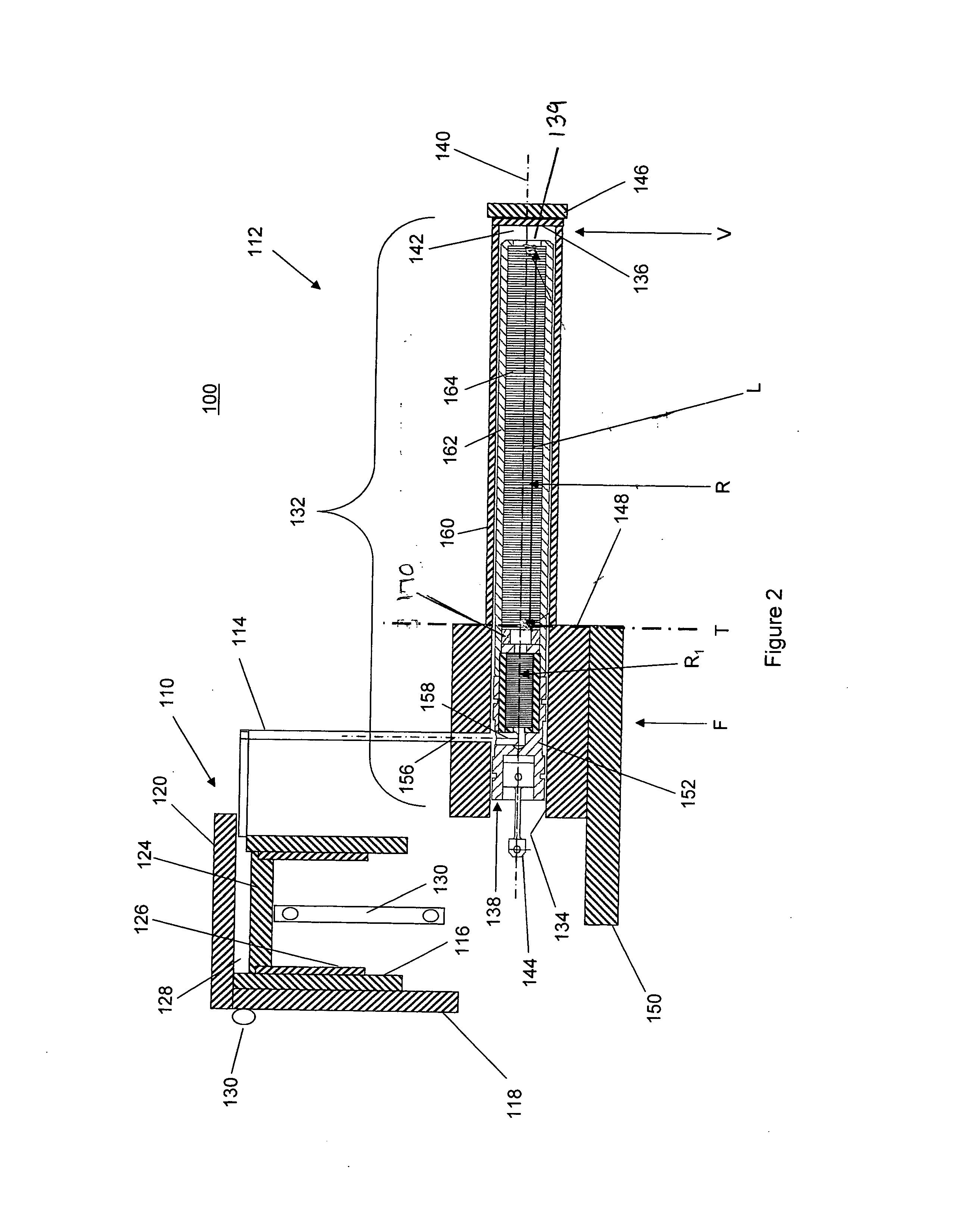

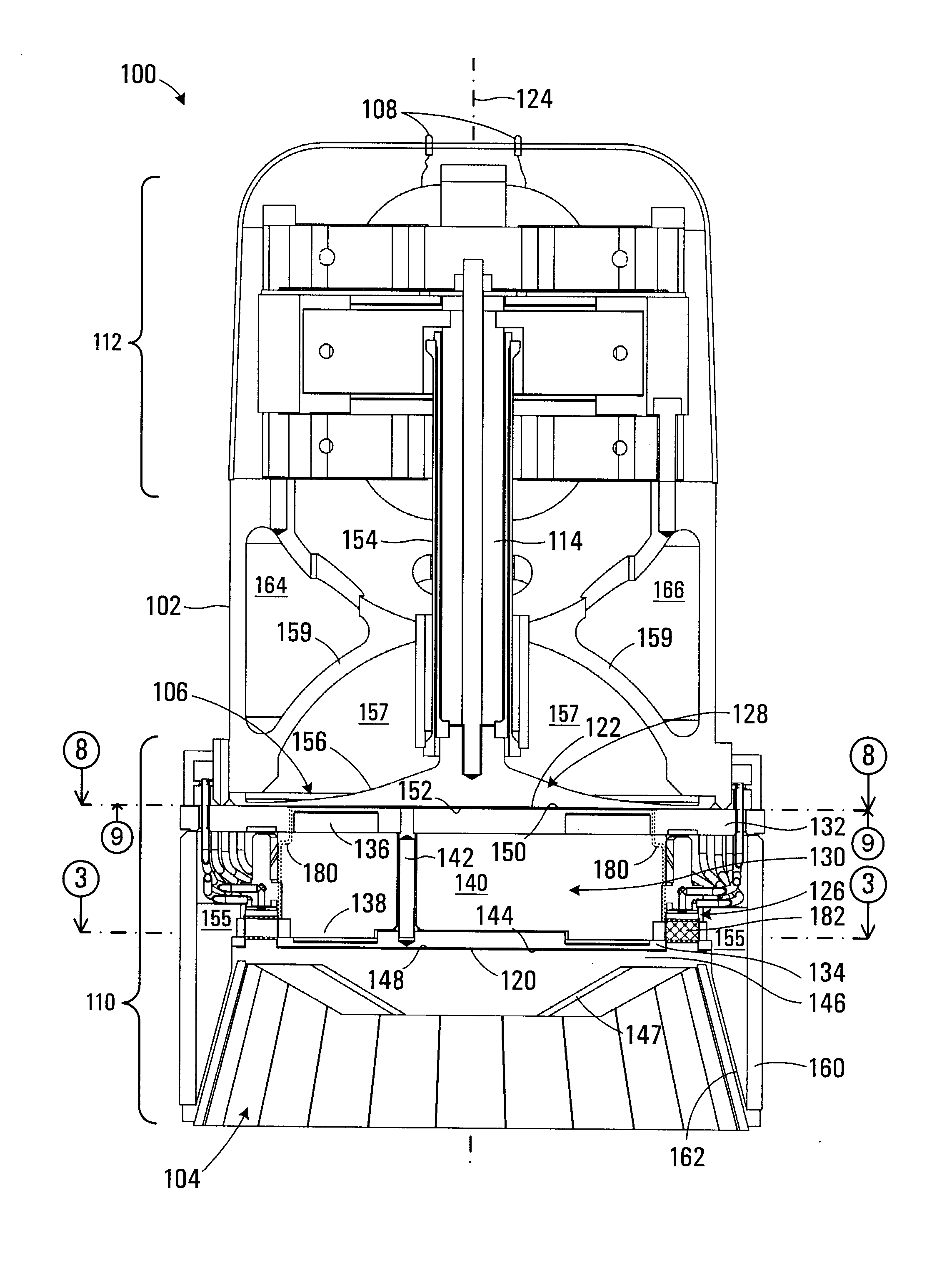

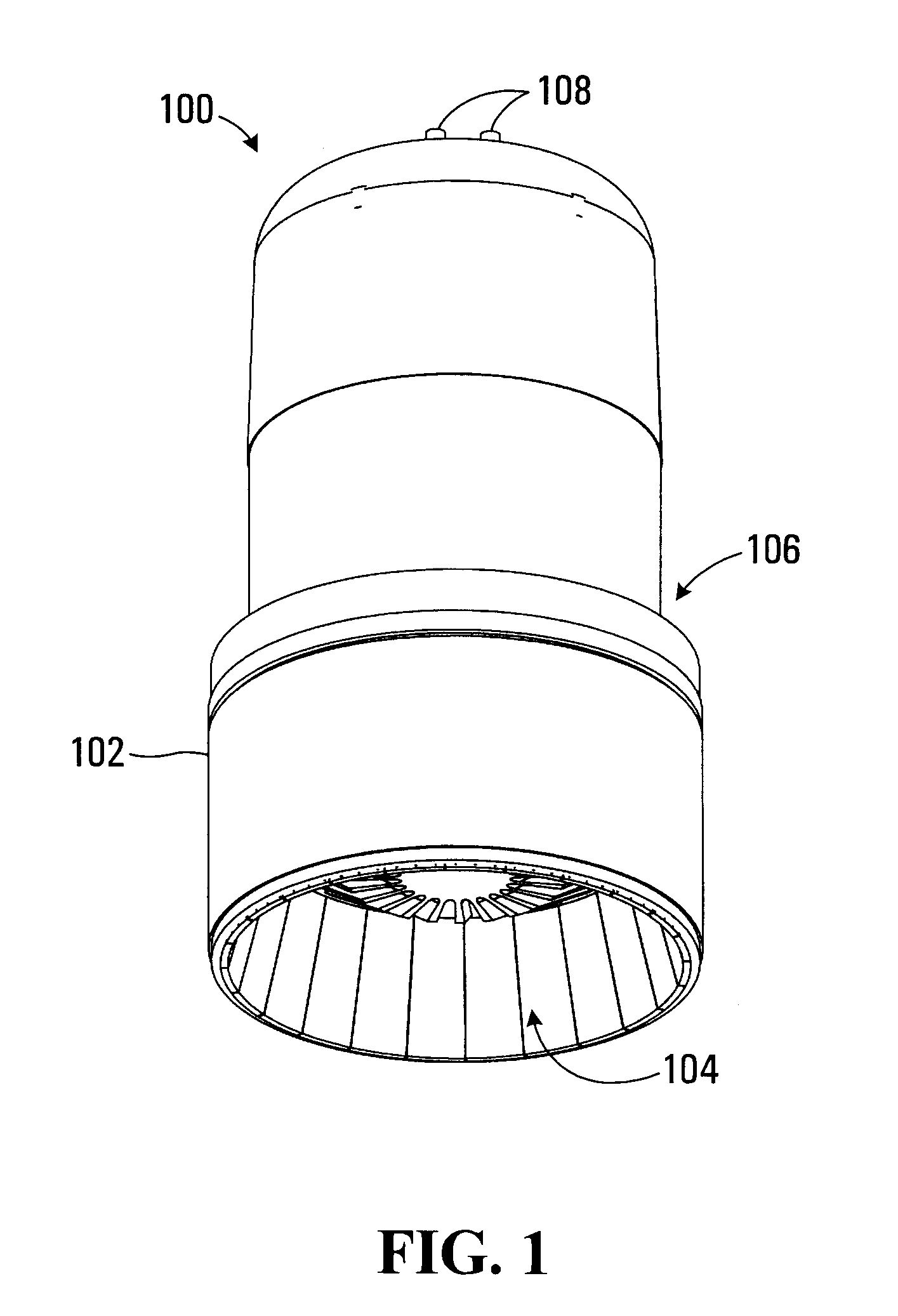

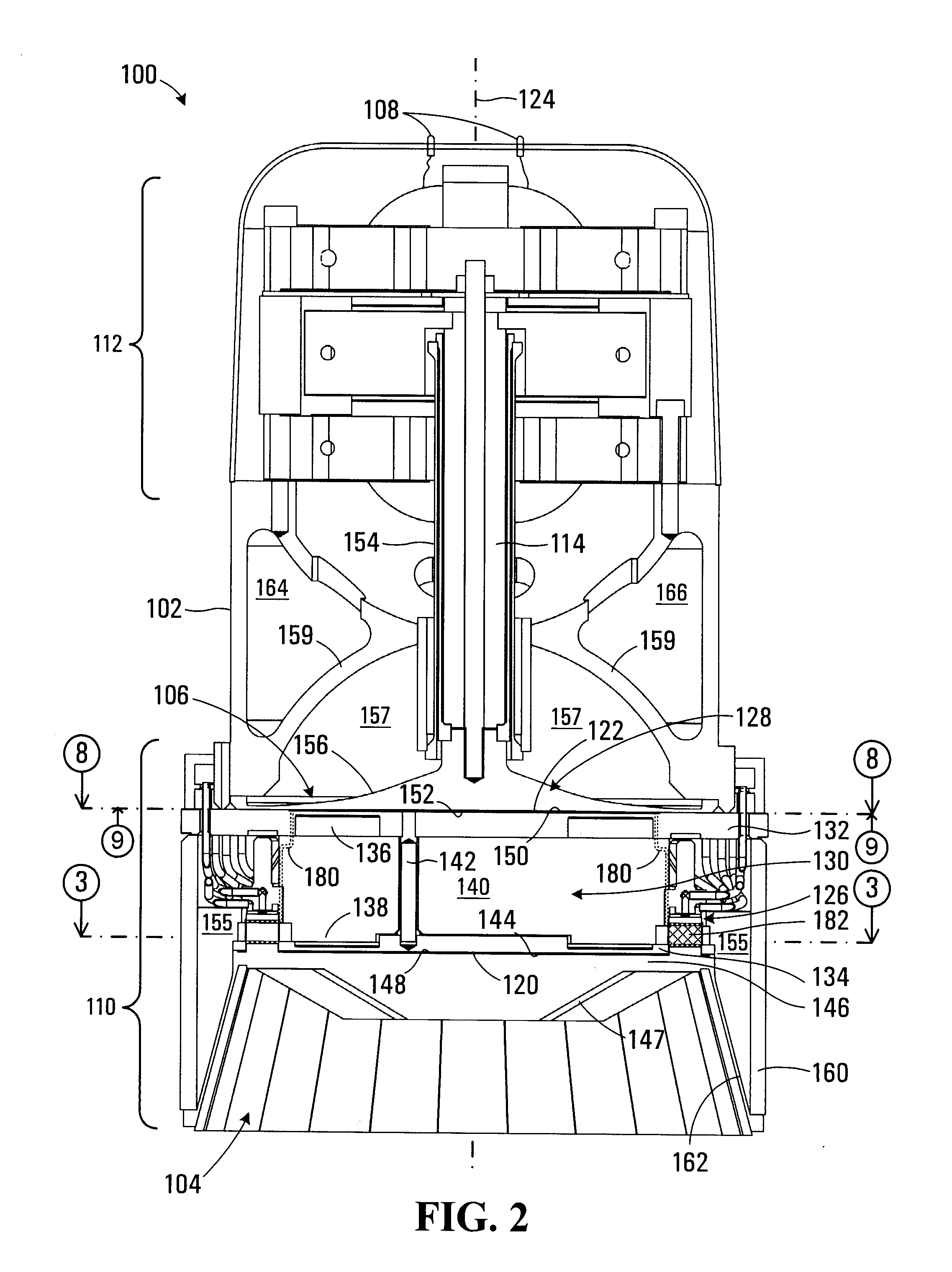

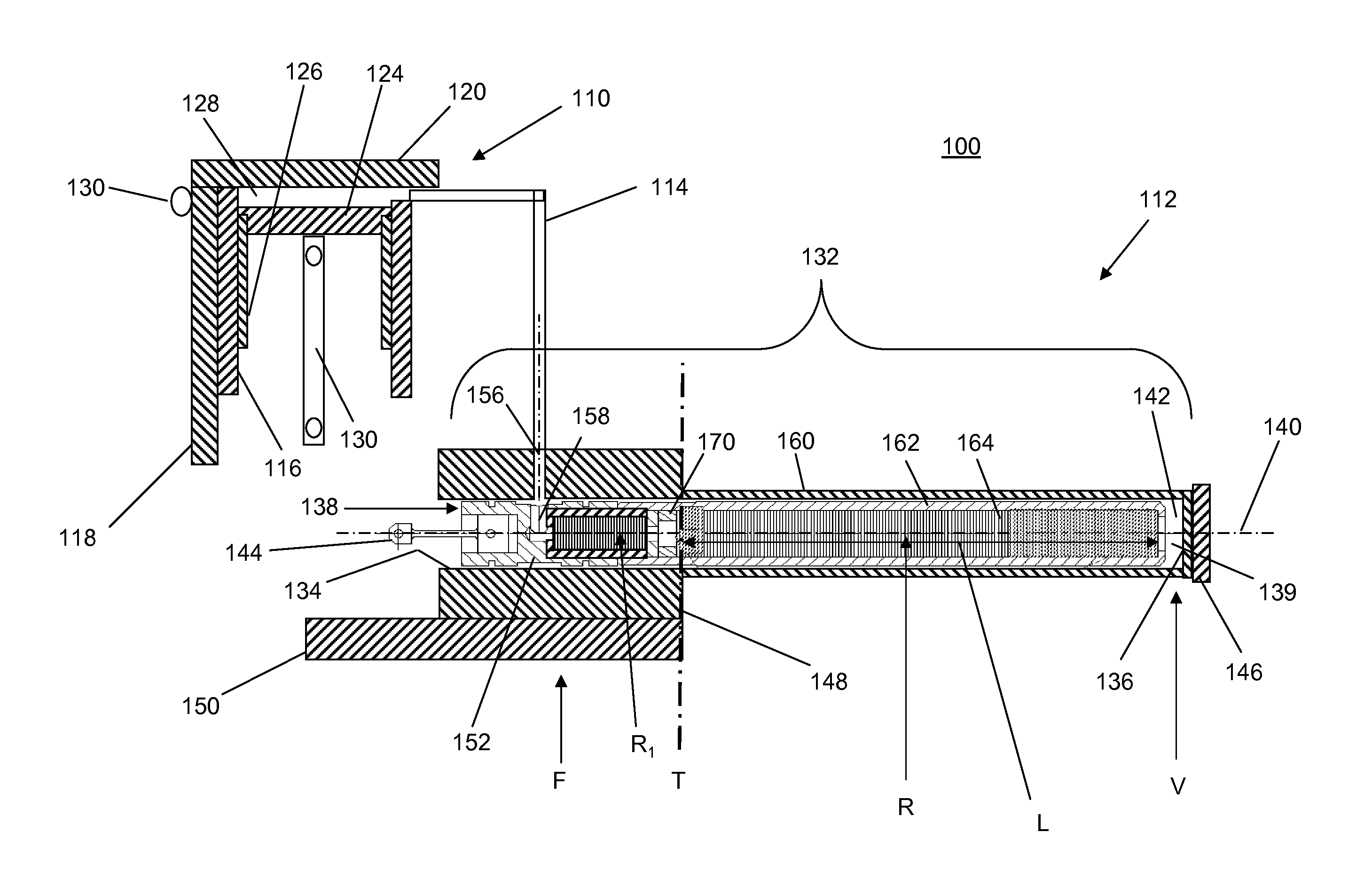

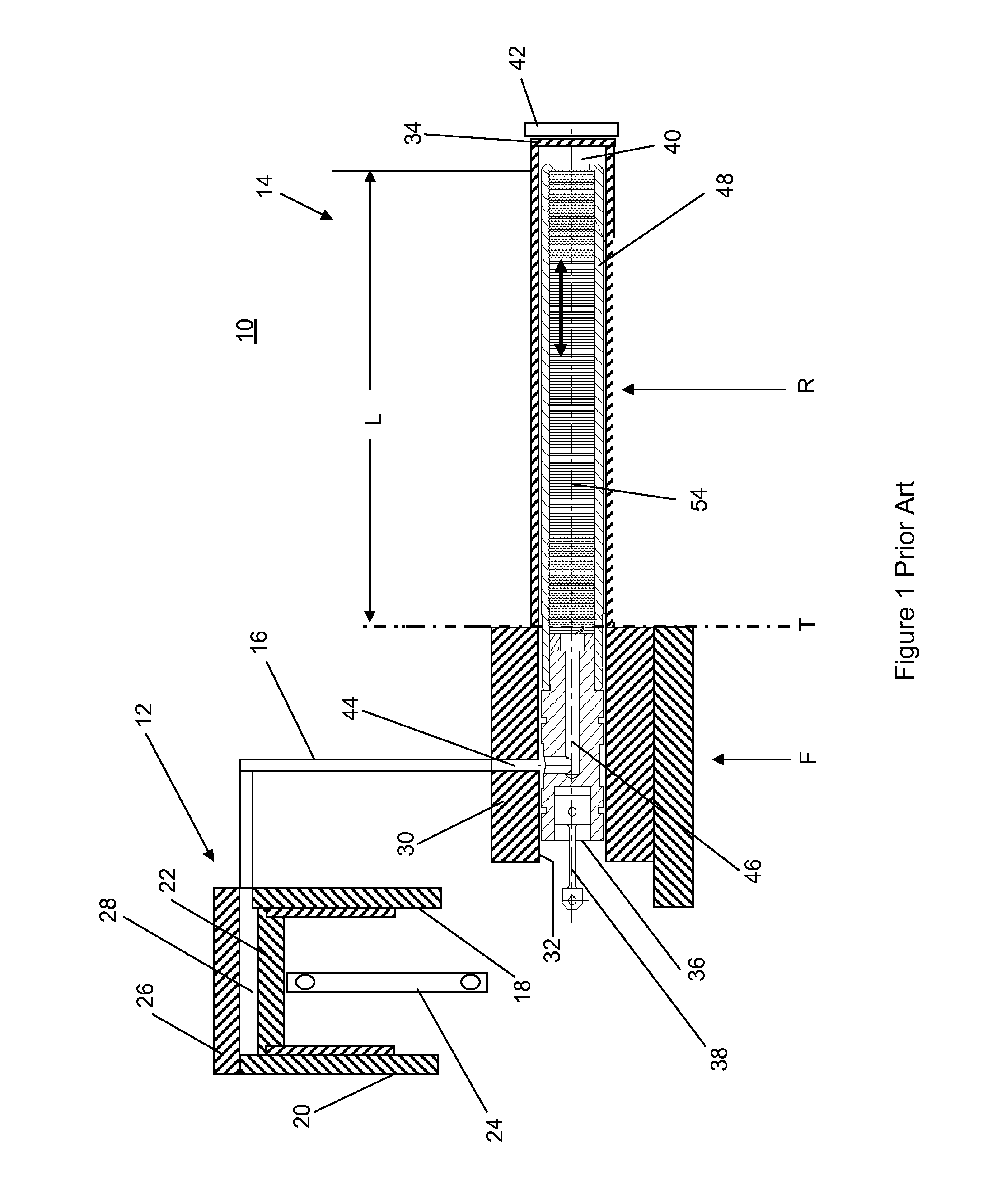

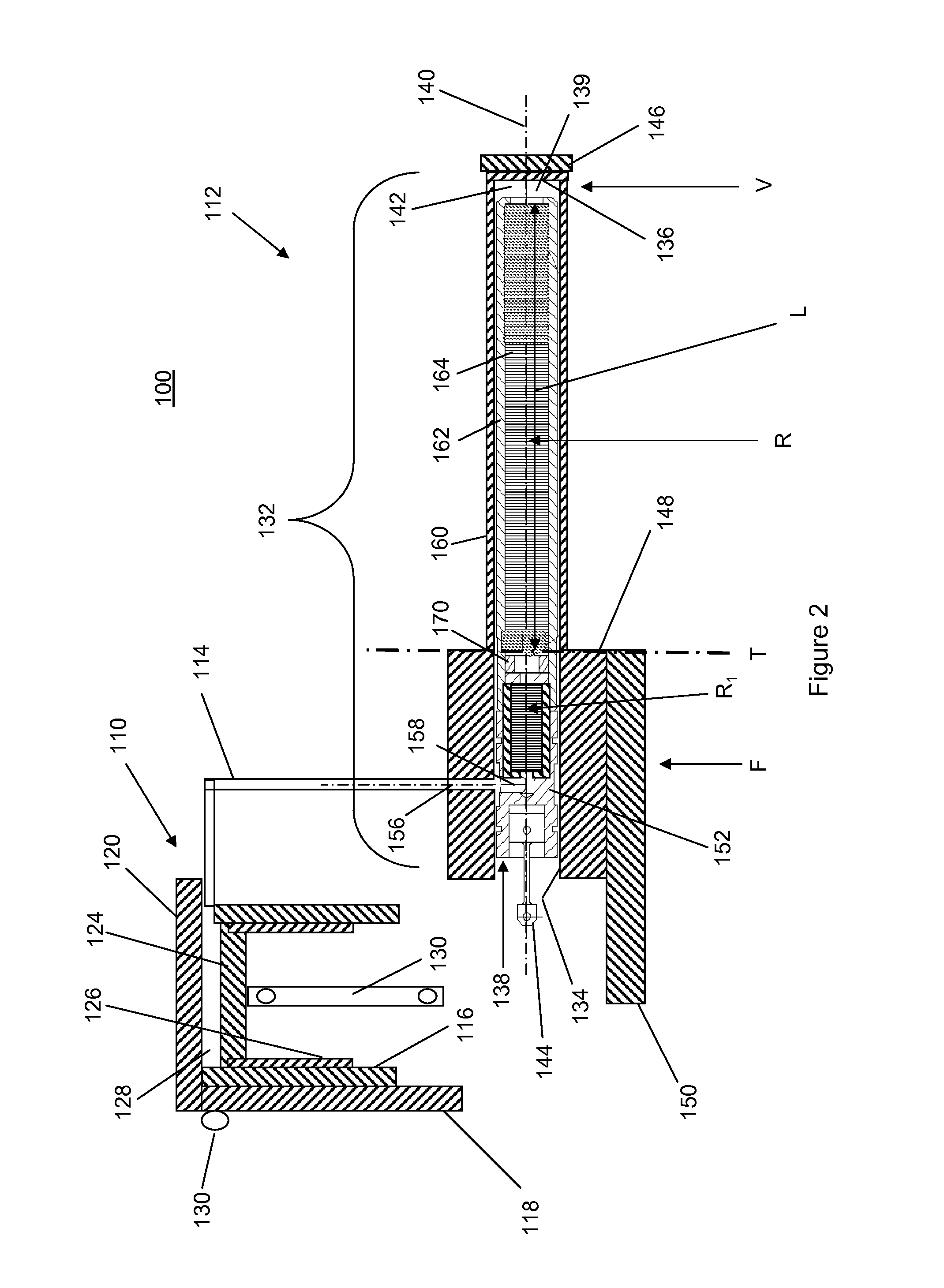

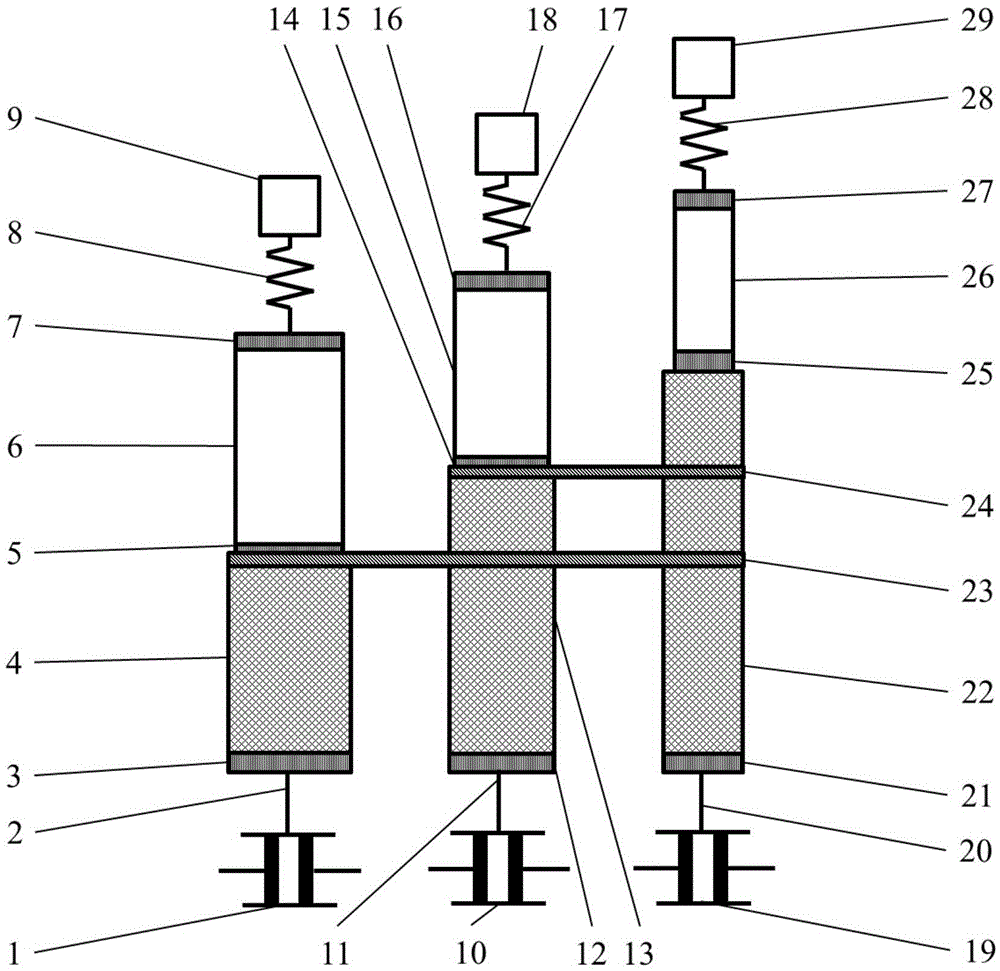

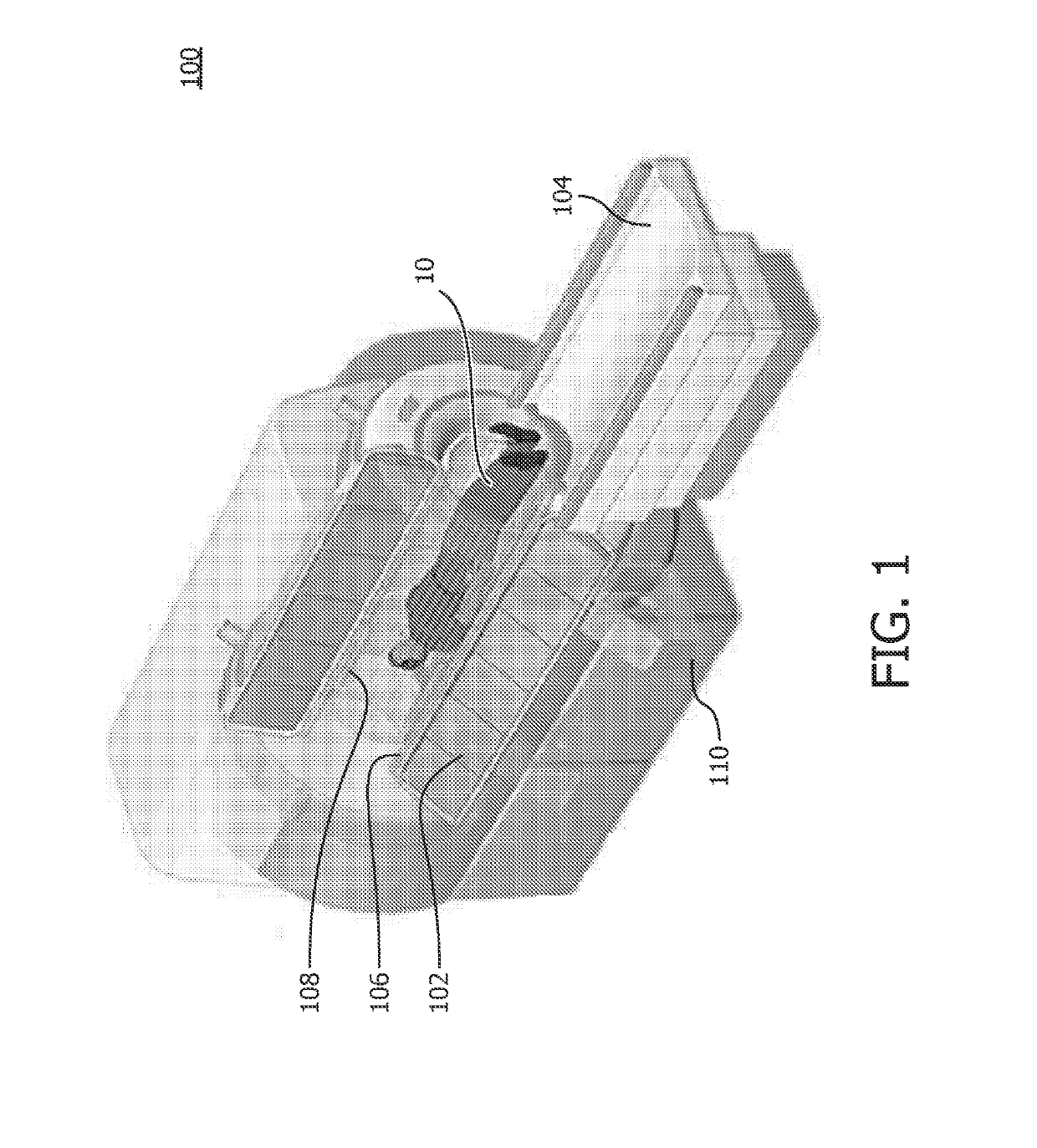

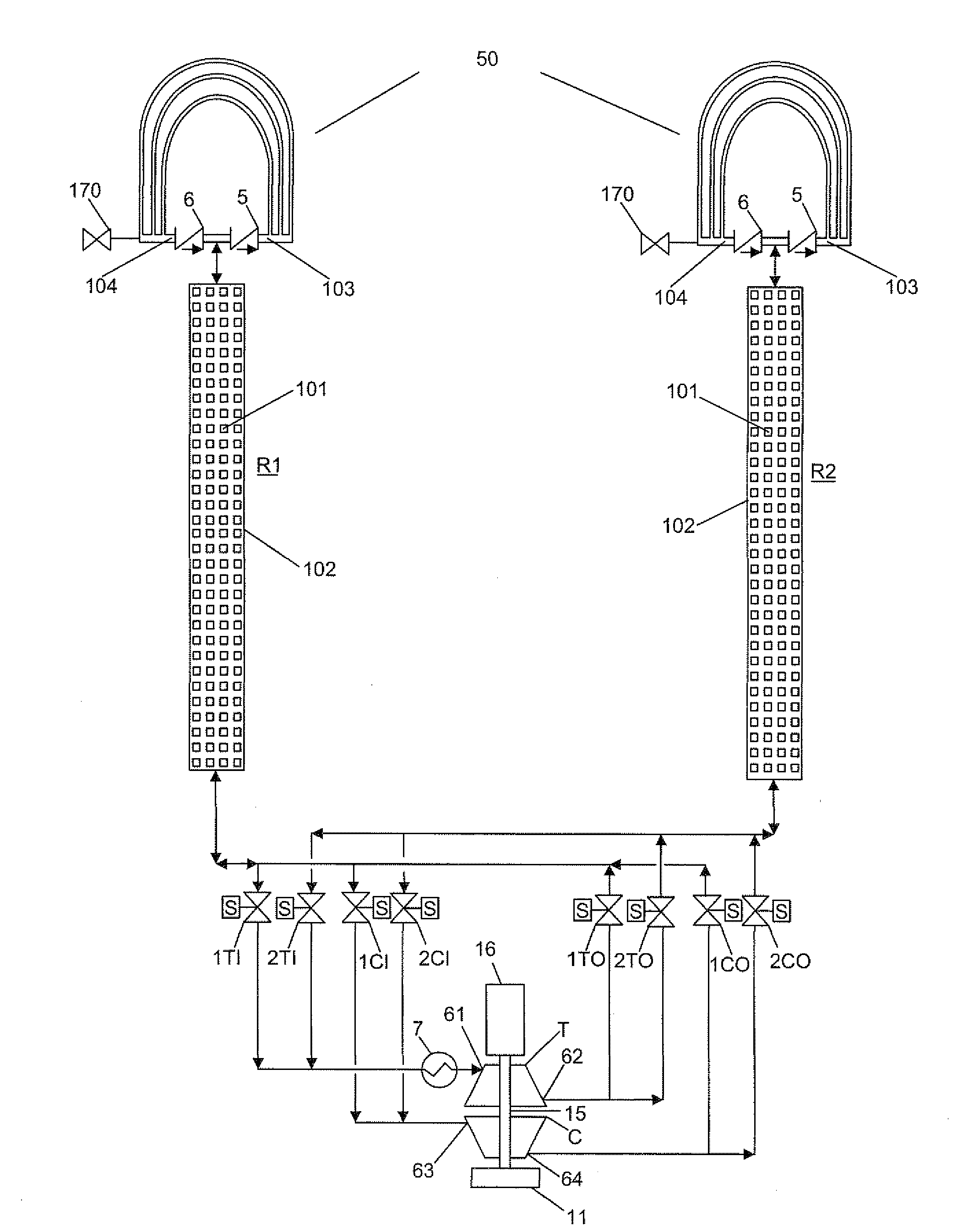

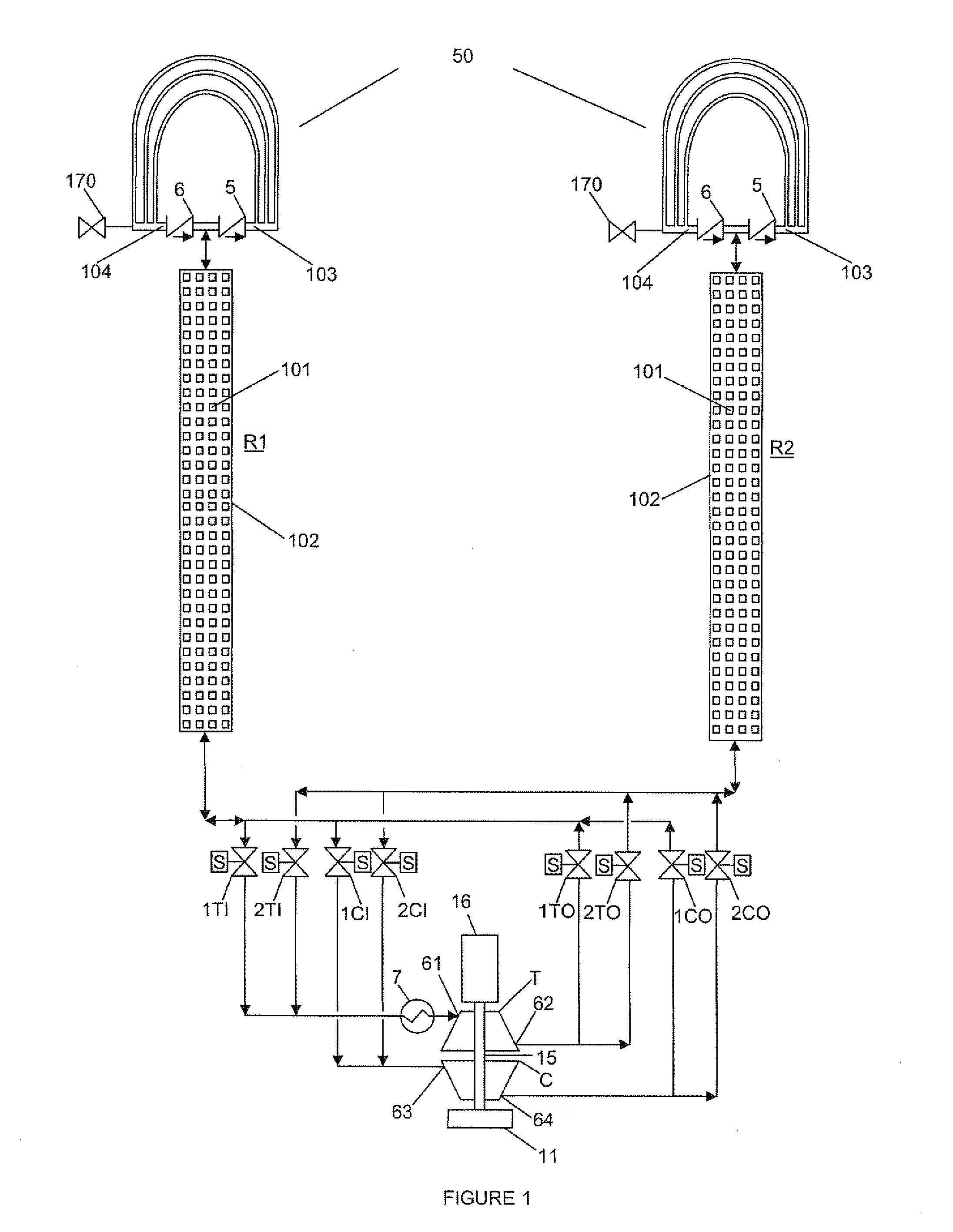

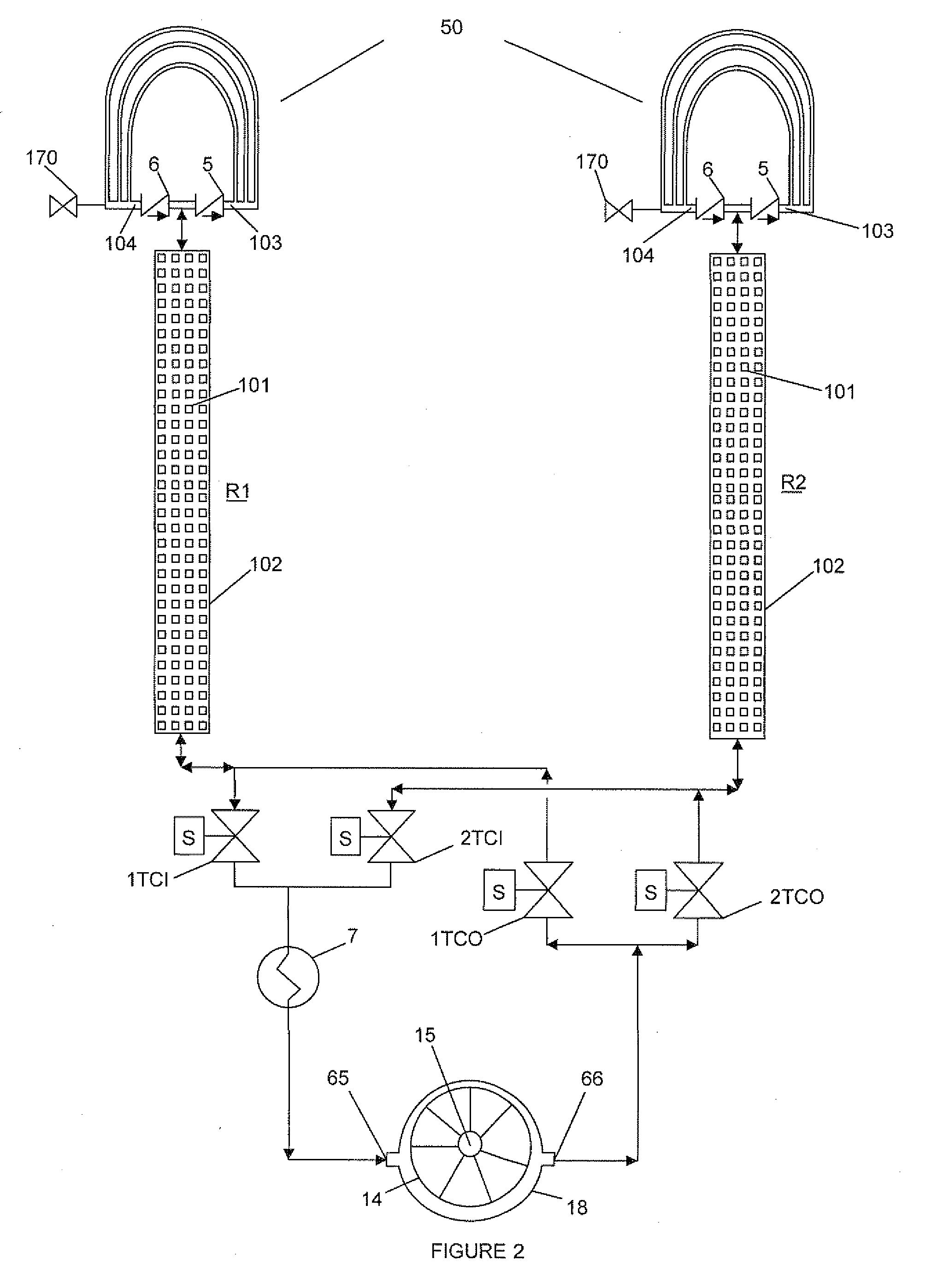

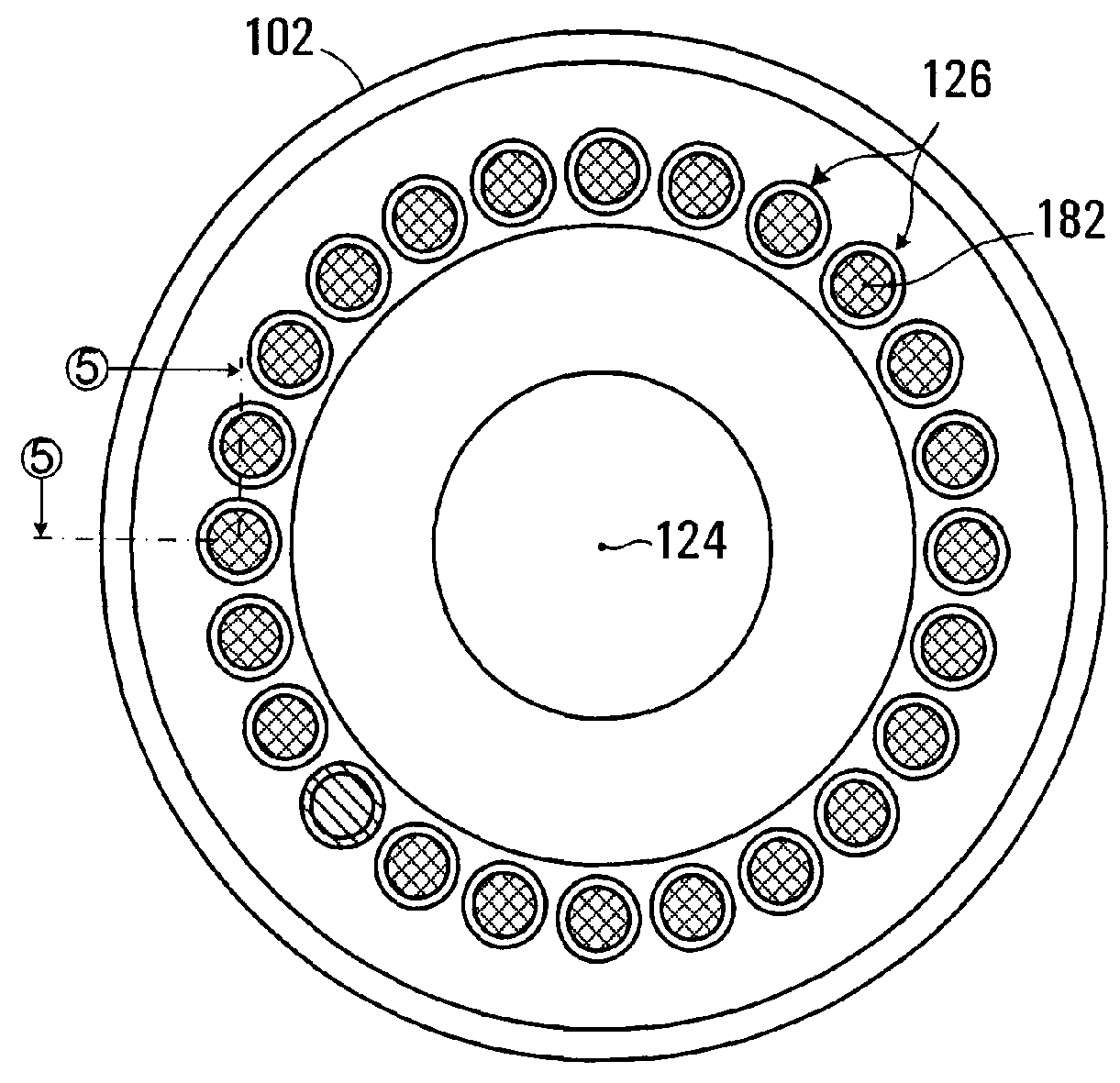

Miniaturized gas refrigeration device with two or more thermal regenerator sections

InactiveUS20070261418A1Increase resistanceCompression machinesGas cycle refrigeration machinesCold sideCryocooler

The size of a miniature cryocooler (100) operating on the Stirling refrigeration cycle is further reduced by shortening a first thermal regenerator module (R) disposed on a cold side of a thermal barrier (T) and providing a second thermal regenerator module (R1) disposed on a warm side of the thermal barrier (T). A thermally insulted fluid flow passage (172) is disposed to interconnect the first and second regenerator modules to thermally insulate the fluid passage (172). In combination, the first and second regenerator modules provide 100% thermal regenerator effectiveness in the device.

Owner:TELEDYNE FLIR LLC

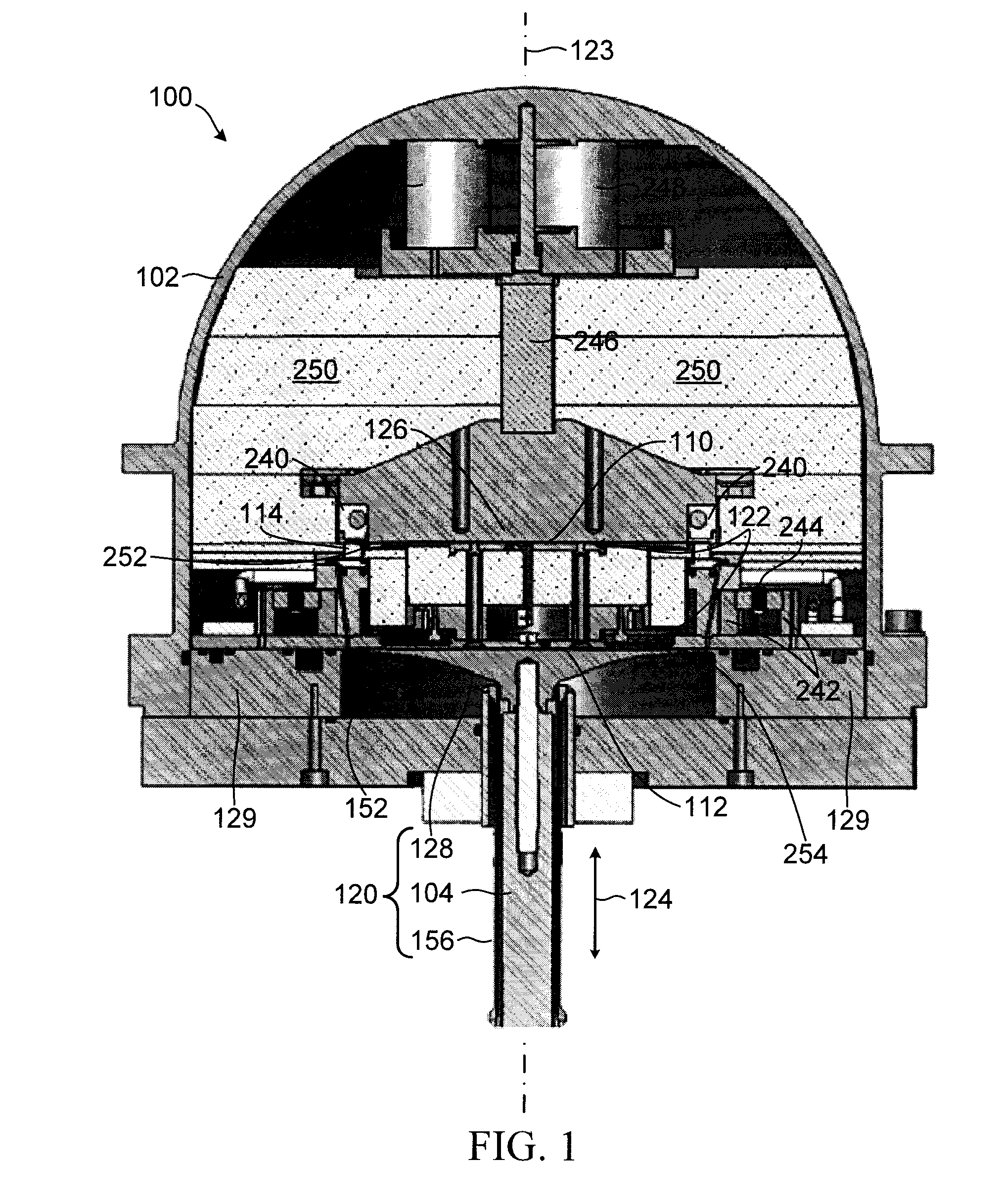

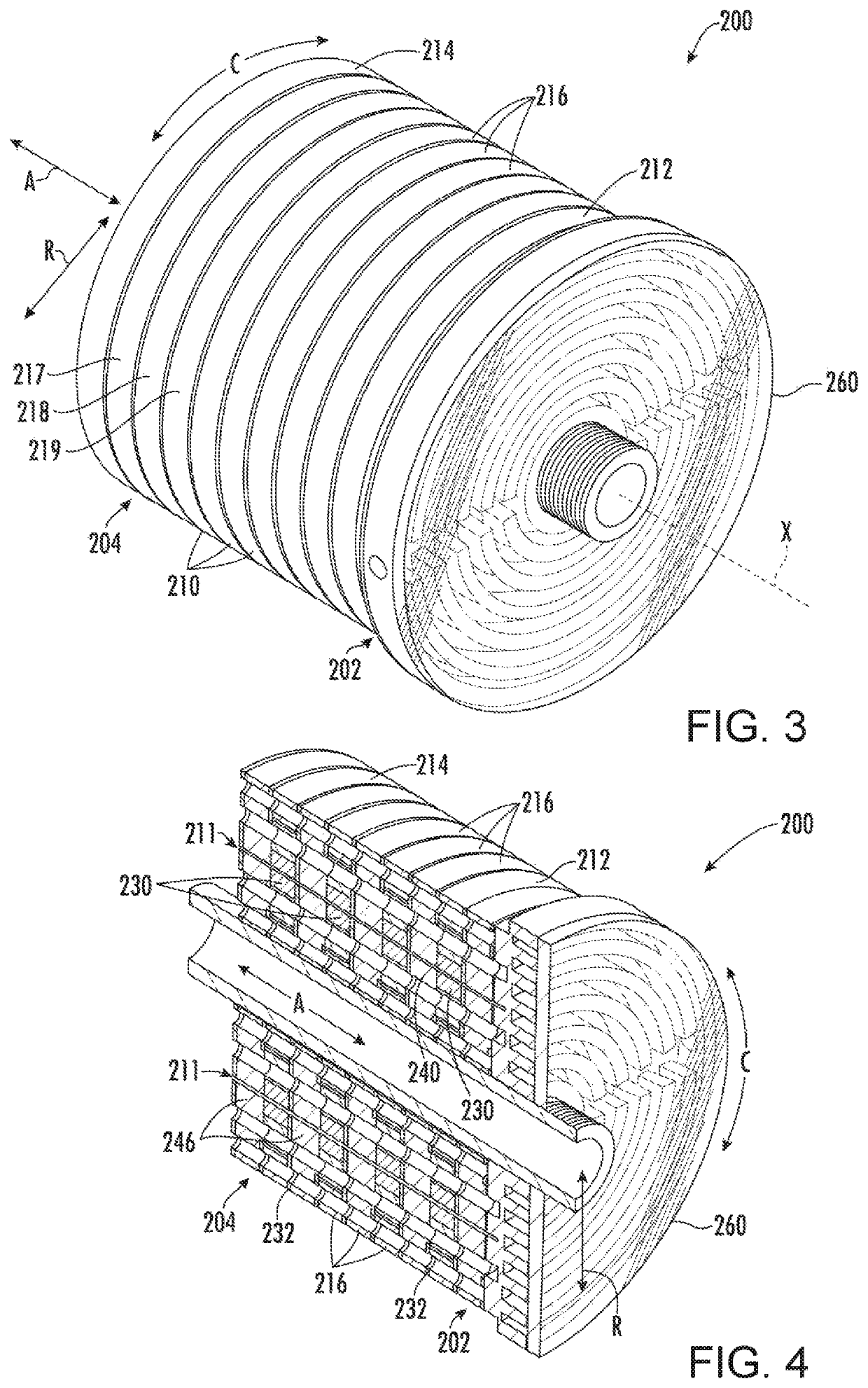

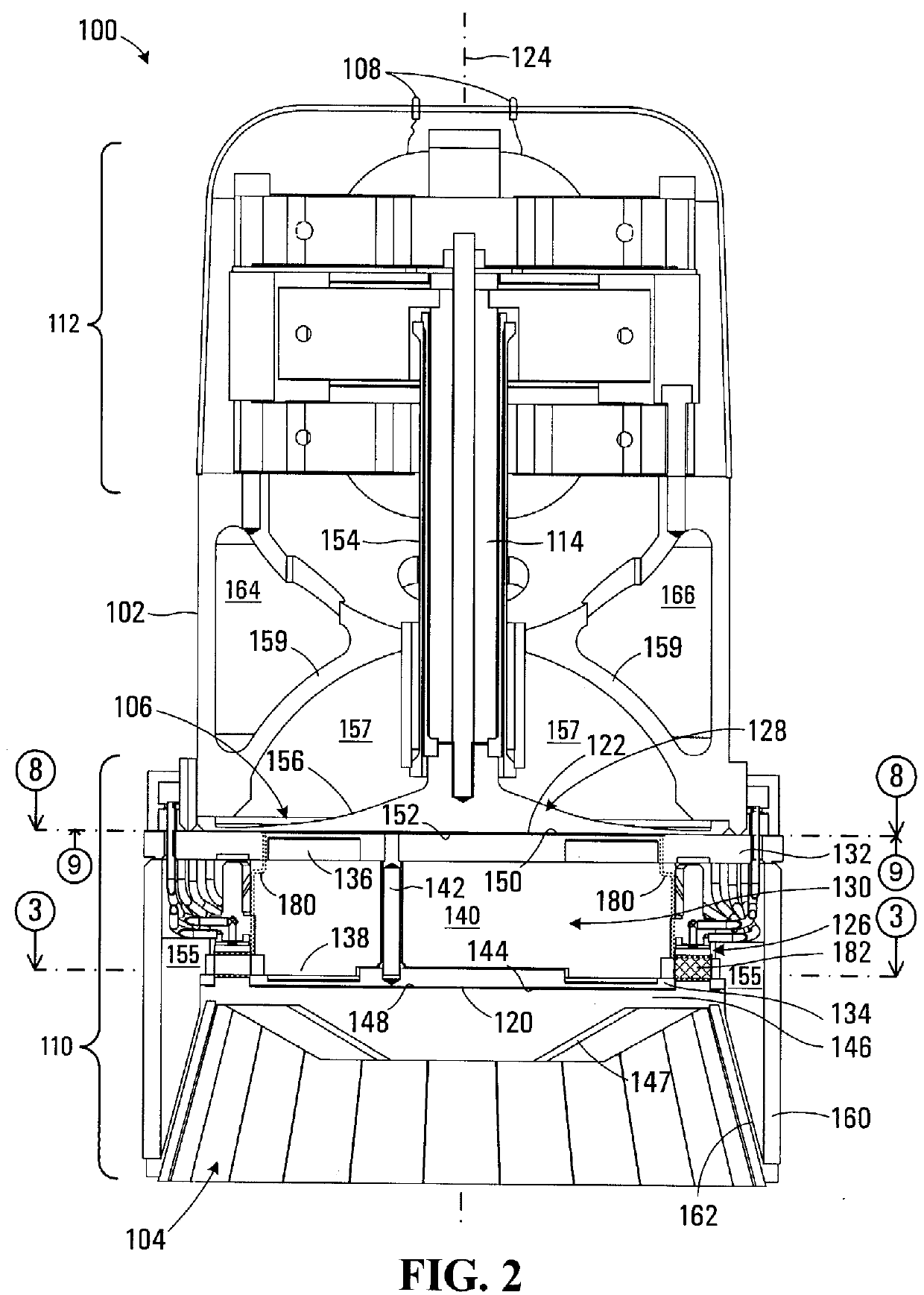

Stirling cycle transducer apparatus

ActiveUS20130239564A1Speed up heat exchangeReduce lossesClosed-cycle gas positive displacement engine plantRegeneratorsTransducerProcess engineering

A communication passage in a Stirling cycle transducer includes a cylindrical shaped thermal regenerator providing flow paths aligned with a regenerator cylindrical axis for providing periodic gas flow between first and second interfaces of the regenerator. A first heat exchanger conveys gas between a periphery of the heat exchanger and the first interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the gas and an external environment in a direction aligned with the regenerator cylindrical axis. A second heat exchanger conveys gas between a periphery of the heat exchanger and the second interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the external environment and the gas in a direction aligned with the regenerator cylindrical axis.

Owner:ETALIM

Superconducting magnet system including thermally efficient ride-through system and method of cooling superconducting magnet system

ActiveCN105745553ACompression machinesDiagnostic recording/measuringSuperconducting CoilsEngineering

A superconducting magnet system, including a cryostat, and a ride-through system for the superconducting magnet system include: one or more gravity-fed cooling tubes configured to have therein a cryogenic fluid; a first heat exchanger configured to transfer heat from the one or more gravity-fed cooling tubes to a cryocooler; a storage device having an input connected to the first heat exchanger and configured to receive and store a boiled-off gas from the first heat exchanger; and a thermal regenerator having an input connected to the output of the storage device.

Owner:KONINKLJIJKE PHILIPS NV

Miniaturized gas refrigeration device with two or more thermal regenerator sections

The size of a miniature cryocooler (100) operating on the Stirling refrigeration cycle is further reduced by shortening a first thermal regenerator module (R) disposed on a cold side of a thermal barrier (T) and providing a second thermal regenerator module (R1) disposed on a warm side of the thermal barrier (T). A thermally insulated fluid flow passage (172) is disposed to interconnect the first and second regenerator modules to thermally insulate the fluid passage (172). In combination, the first and second regenerator modules provide 100% thermal regenerator effectiveness in the device.

Owner:TELEDYNE FLIR LLC

Thermal regenerator for exhaust system

An exhaust component includes a housing defining an internal cavity and a burner positioned within the internal cavity. The burner provides a combustion chamber having an exhaust gas inlet, a fuel inlet, a combustion air inlet, and an outlet. At least one exhaust aftertreatment component is positioned within the internal cavity and is directly coupled to the outlet of the combustion chamber.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

Minitype thermoacoustic refrigerator module device

InactiveCN1829430ATo achieve the purpose of coolingEliminate hot spotsSemiconductor/solid-state device detailsCompression machinesEngineeringRefrigerated temperature

The present invention relates to a miniature thermo - acoustic refrigerating module device utilizing thermo-acoustical effect acoustical effect to proceed heat radiation or refrigerating to electronic optoelectronic device optoelectronic device and chip. It contains front drove membrane coil, front end permanent magnetism membrane, hot end heat exchanger, hot end heat exchanger extended surface, cold end heat exchanger, thermal regenerator, frame (resonant cavity resonant cavity), cold end heat exchanger extended surface, rear end membrane coil, rear end permanent magnetism membrane, hot end heat exchanger, diathermic membrane etc. Individual module refrigerating capacity is greater than 200 mw, refrigerating temperature difference being 30 degree centigrade. The present invention fully utilizes thermo-acoustic heat engine advantage to realize cooling chip, eliminating chip hotspot, and chip reliable operation.

Owner:CENT SOUTH UNIV

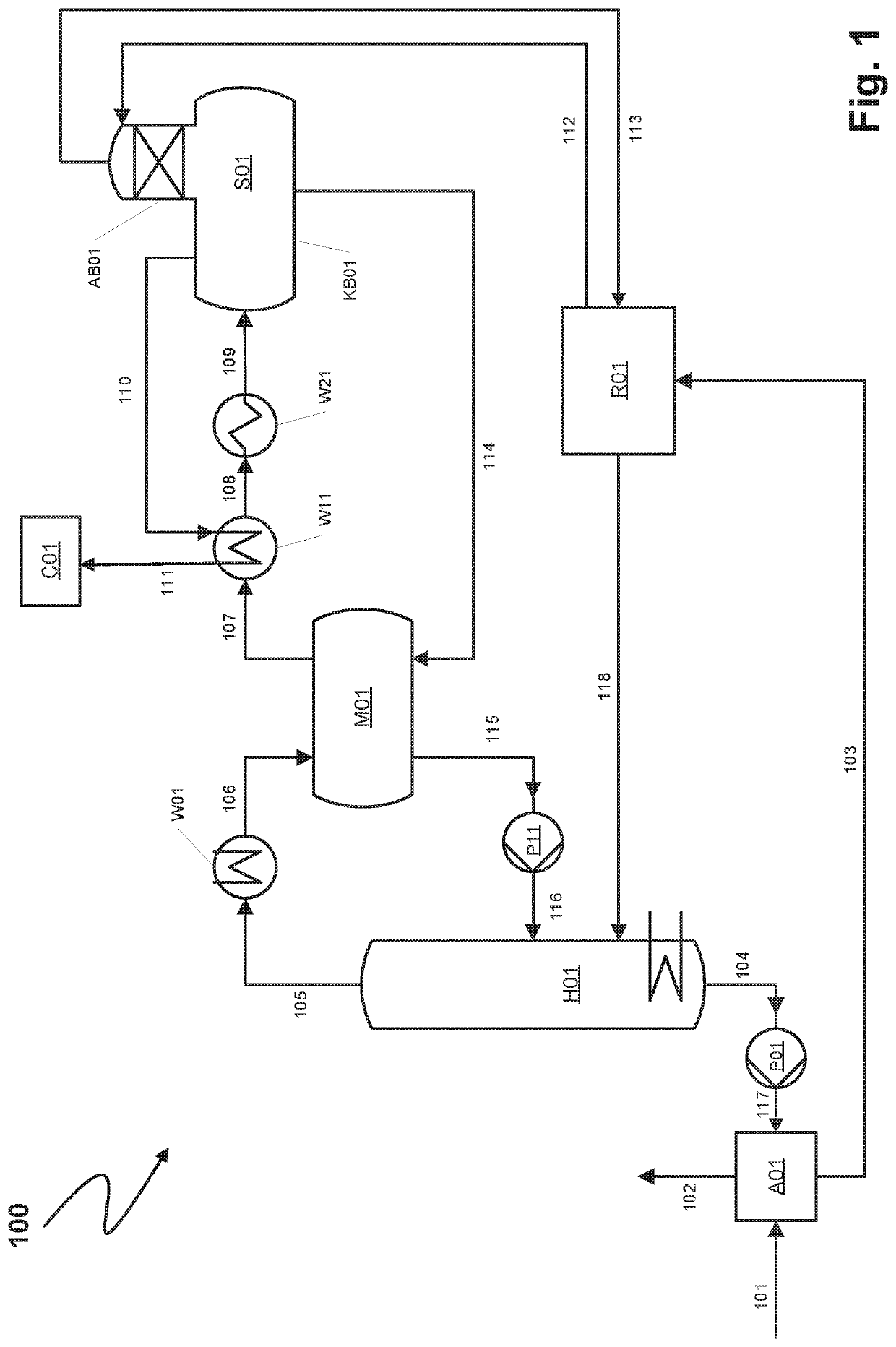

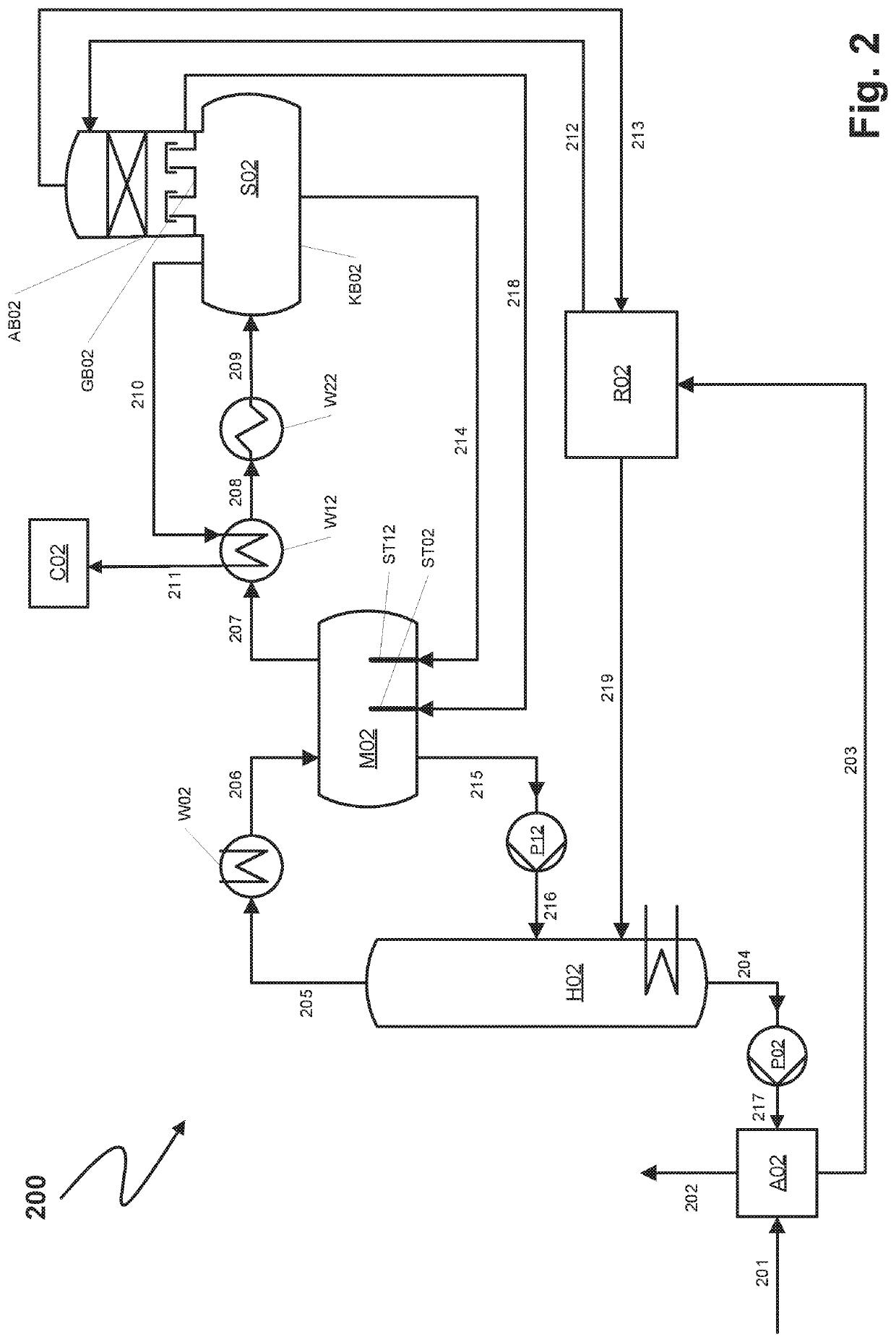

Process for purifying crude synthesis gas to produce an acid gas and acid gas separator

ActiveUS20200101415A1Promote absorptionReduce usageGas treatmentHydrogen separation at low temperaturePhysical chemistryAmmonia

The invention relates to a gas scrubbing process for purifying crude synthesis gas with methanol as a physical absorption medium, wherein an acid gas comprising at least hydrogen sulfide (H2S) is produced. The acid gas is produced in a hot regenerator arranged downstream of an absorption apparatus and subsequently separated from gaseous methanol in an acid gas separator by cooling and condensation. The acid gas separator has a condensation region and an absorption region, wherein both regions are separated from one another by a gas-permeable tray. This has the result that impurities such as hydrogen cyanide and / or ammonia outgassing from a first acid gas substream are not reabsorbed in the condensation region of the acid gas separator, thus avoiding an accumulation of impurities in the hot regenerator or other parts of the gas scrubbing plant. The invention further relates to an acid gas separator and to the use of the acid gas separator according to the invention in a process according to the invention.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

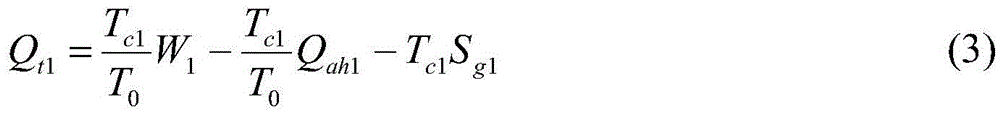

Design method for three-level thermal coupling type high-frequency pulse tube refrigerating machine based on entropy analysis

InactiveCN105423588AMaster the distribution of lossesImprove efficiencyCompression machinesRefrigeration safety arrangementThree levelReduced model

The invention discloses a design method for a three-level thermal coupling type high-frequency pulse tube refrigerating machine based on entropy analysis. The design method includes six steps that firstly, a model is established; secondly, a reasonable fundamental assumption is established, and the model is simplified; thirdly, the performance of the first level is analyzed based on entropy analysis; fourthly, the performance of the second level is analyzed based on the previous research; fifthly, the previous analysis result is substituted into the third level, and the analysis relation between the refrigerating performance of the third level and various levels of work parameters is obtained; and sixthly, various work parameters including the input sound power, the refrigerating temperature, the inflation pressure, the pressure ratio, the work frequency, the thermal regenerator size, the thermal bridge connecting position, the cold storage padding and the like of various levels are optimally designed according to actual needs based on the simulation result, and the optimal work state is achieved. According to the design method, various irreversible losses can be obviously reduced, the refrigerating efficiency of a system is improved, and important significance is achieved for practical development of the three-level thermal coupling type high-frequency pulse tube refrigerating machine.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

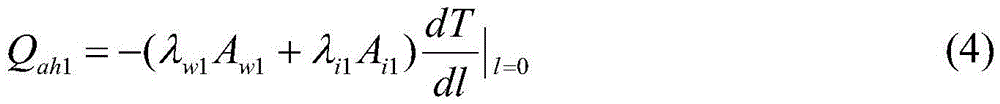

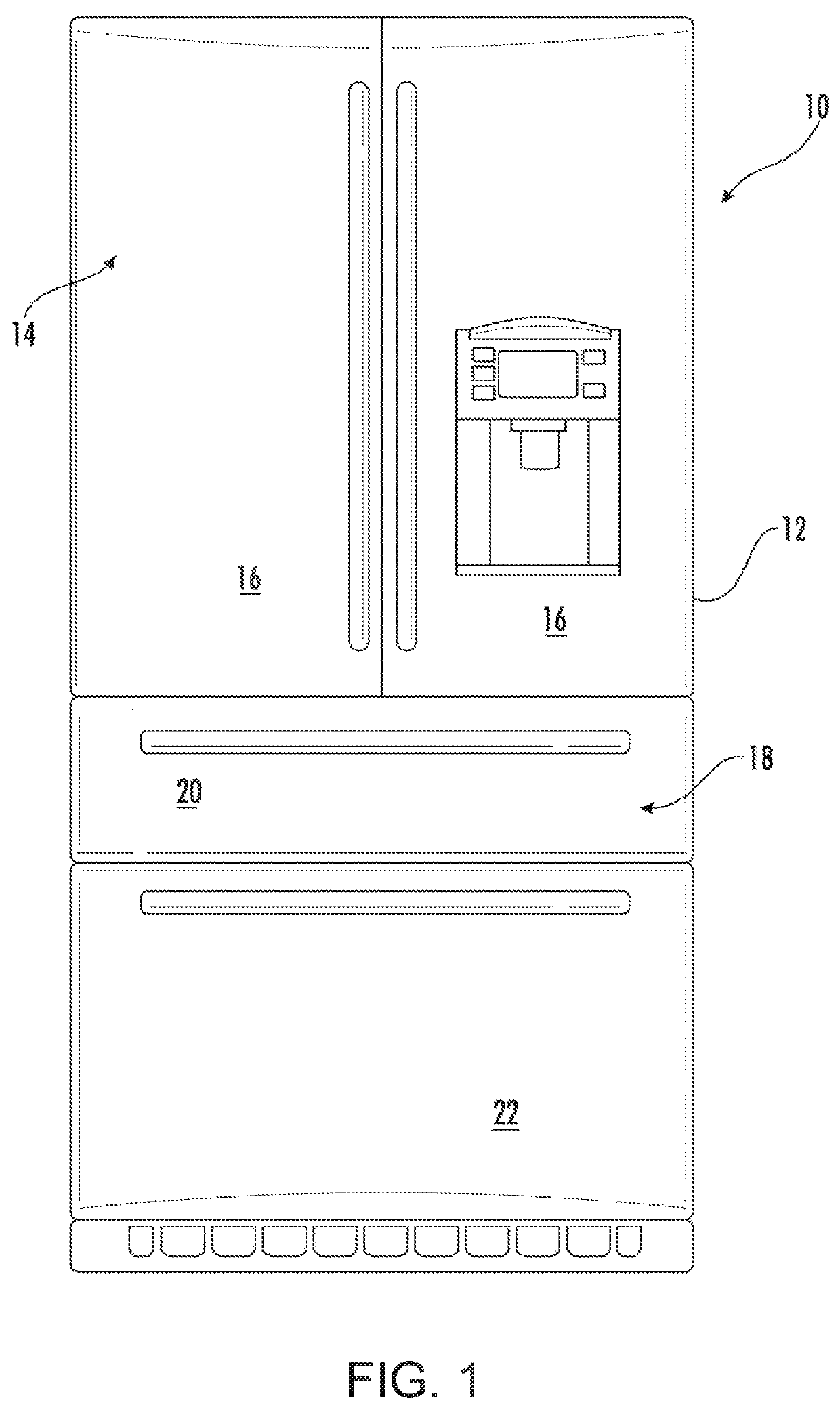

Magneto-caloric thermal diode assembly

ActiveUS10782051B2Inorganic material magnetismMachines using electric/magnetic effectsMetal foilEngineering

Owner:HAIER US APPLIANCE SOLUTIONS INC

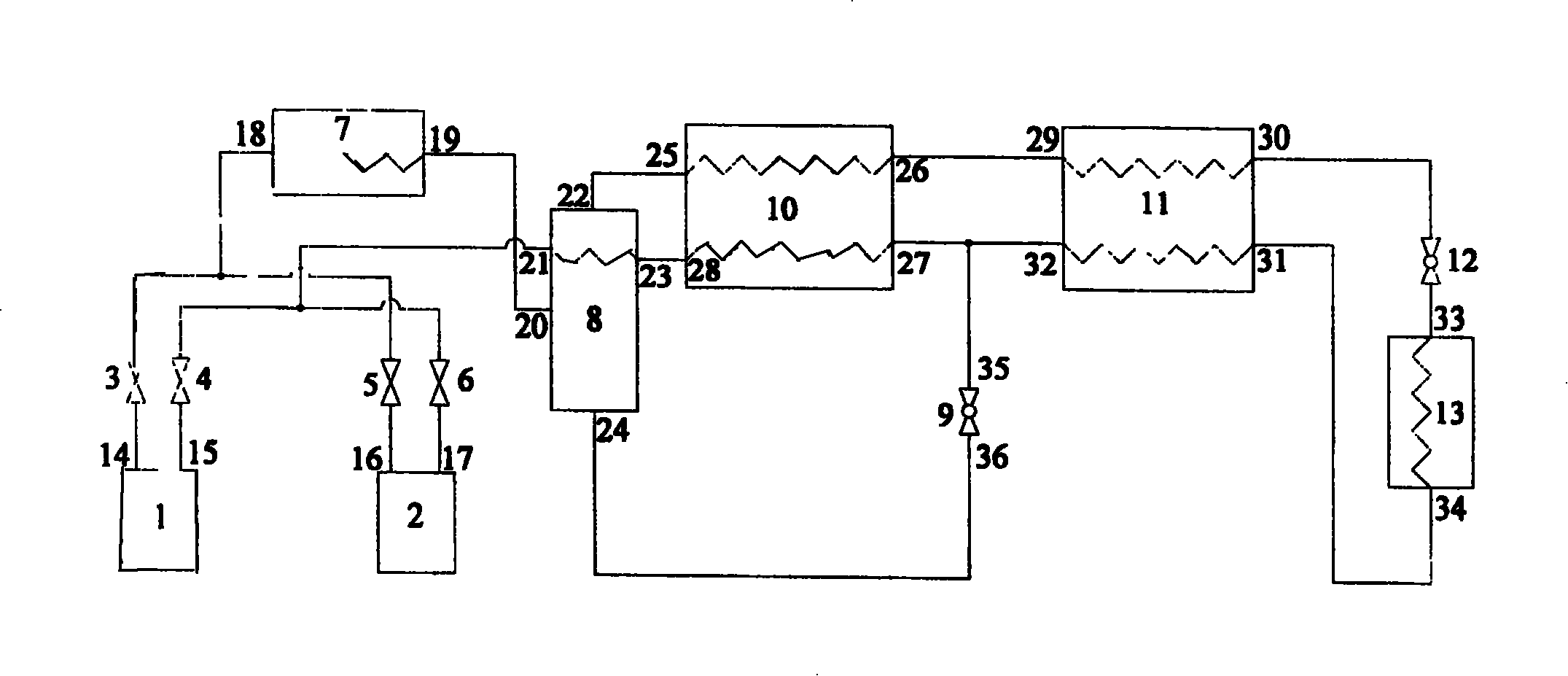

Mixed working medium deep-freezing adsorption refrigerating device

InactiveCN1815110AImprove efficiencySimple structureEnergy efficient heating/coolingClimate change adaptationAdsorption refrigerationDesorption

Present invention discloses a mixing working medium deep refrigeration deep refrigeration adsorption refrigerator. It in turn connected first sorption / desorption unit, second sorption / desorption unit, condensator, constituent element separation module, second throttling set, second thermal regenerator, first thermal regenerator, first throttling set and evaporator, solid sorbent installed in first sorption / desorption unit and second sorption / desorption unit. Said invention applies self overlapping mixing working medium refrigerator principle to adsorption refrigeration system to fully utilize different kinds of high low temperature waste heat low temperature waste heat low temperature waste heat, to simplify tradition overlapping type adsorption refrigeration system realizing -60 to -200 degree centigrade deep refrigeration with simple structure, reliable performance, and high efficiency.

Owner:ZHEJIANG UNIV

Superconducting magnet system including thermally efficient ride-through system and method of cooling superconducting magnet system

ActiveUS10403423B2Compression machinesDiagnostic recording/measuringNuclear engineeringSuperconducting Coils

A superconducting magnet system, including a cryostat, and a ride-through system for the superconducting magnet system include: one or more gravity-fed cooling tubes configured to have therein a cryogenic fluid; a first heat exchanger configured to transfer heat from the one or more gravity-fed cooling tubes to a cryocooler; a storage device having an input connected to the first heat exchanger and configured to receive and store a boiled-off gas from the first heat exchanger; and a thermal regenerator having an input connected to the output of the storage device.

Owner:KONINKLJIJKE PHILIPS NV

Maximized Thermal Efficiency Engines

InactiveUS20120067040A1Easy to useEricsson type enginesClosed-cycle gas positive displacement engine plantThermal energyEngineering

This disclosure provides a method for efficiently converting heat energy to readily usable energy with maximized thermal efficiency. Maximized thermal efficiency is obtained by the use of heat regeneration and working gas processing steps that optimize the heat regeneration, so that any heat that is supplied to the working gas from the external heat sourse is supplied at the maximum temperature, and any heat that is rejected from the working gas to an external heat sinks is rejected at the minimum temperature, given the constraints of the the heat source and heat sink temperatures. Two basic designs of engines are proposed. One of the basic designs uses pairs of heat regenerators, and would be suitable for stationary power generation applications. The other basic design uses single heat regenerators and would be suited for motive power applications. Both piston cylinder and turbocompressor driven engine applications can be used in each of the two basic designs of engines.

Owner:PINTO ADOLF PATRICK

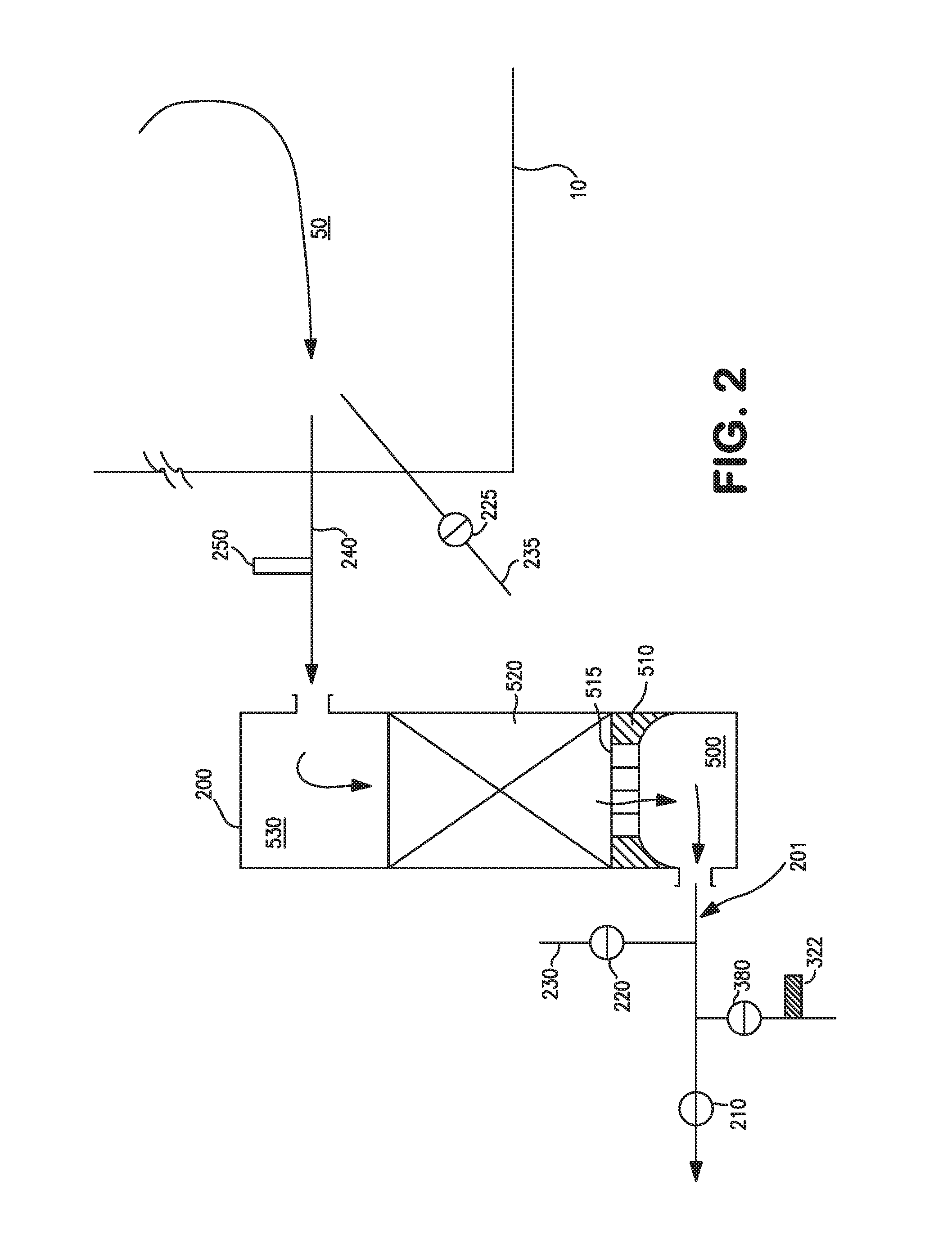

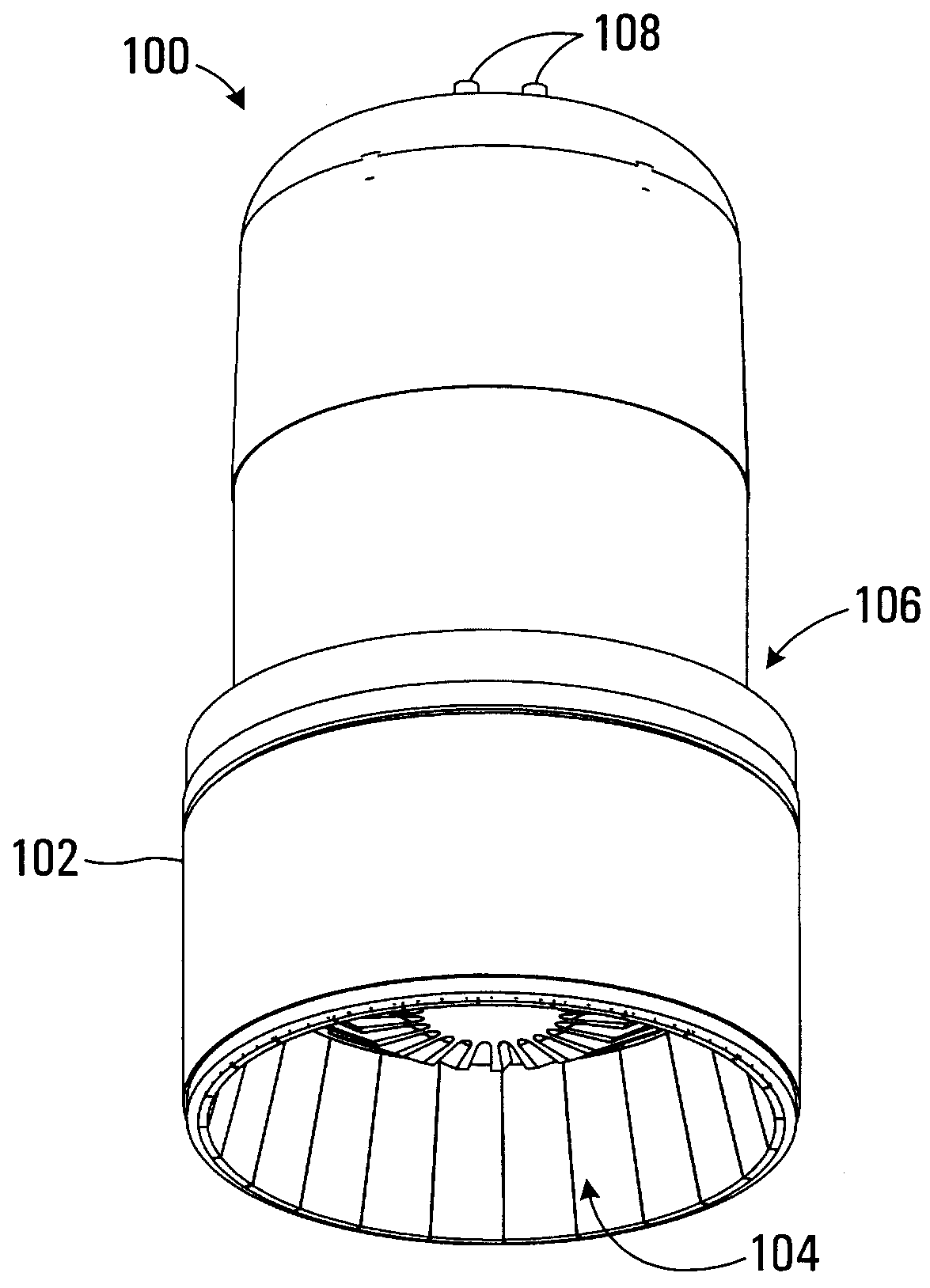

Thermal regenerator for exhaust system

ActiveUS20200123953A1Increase exhaust temperatureInternal combustion piston enginesExhaust apparatusCombustion chamberCombustor

An exhaust component includes a housing defining an internal cavity and a burner positioned within the internal cavity. The burner provides a combustion chamber having an exhaust gas inlet, a fuel inlet, a combustion air inlet, and an outlet. At least one exhaust aftertreatment component is positioned within the internal cavity and is directly coupled to the outlet of the combustion chamber.

Owner:FAURECIA EMISSIONS CONTROL TECH GERMANY

Thermal acoustic passage for a stirling cycle transducer apparatus

ActiveUS9382874B2Speed up heat exchangeReduce lossesClosed-cycle gas positive displacement engine plantRegeneratorsThermoacousticsTransducer

A communication passage in a Stirling cycle transducer includes a cylindrical shaped thermal regenerator providing flow paths aligned with a regenerator cylindrical axis for providing periodic gas flow between first and second interfaces of the regenerator. A first heat exchanger conveys gas between a periphery of the heat exchanger and the first interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the gas and an external environment in a direction aligned with the regenerator cylindrical axis. A second heat exchanger conveys gas between a periphery of the heat exchanger and the second interface causing a change of direction of gas flow between radially and axially oriented flow within the regenerator and transfers heat between the external environment and the gas in a direction aligned with the regenerator cylindrical axis.

Owner:ETALIM

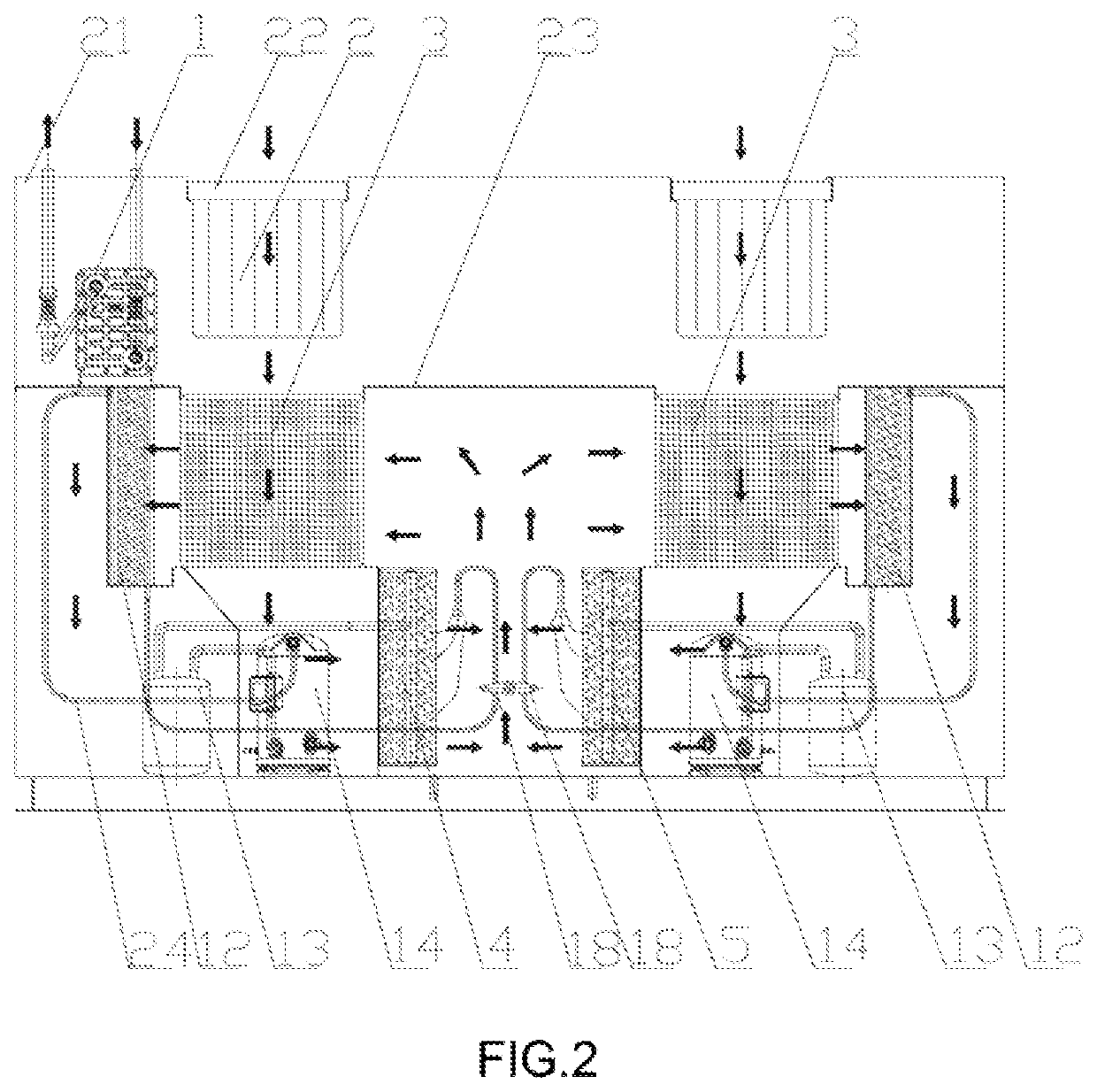

Automatic constant-temperature dehumidification device

ActiveUS20210284561A1Reduce decreasePrevent dried dustWater treatment parameter controlSludge treatment by de-watering/drying/thickeningCold sideVentilation tube

An automatic constant-temperature dehumidification device, comprising at least two dehumidification heat pump assemblies having two refrigerant modules and an air module. The refrigerant module comprises a primary refrigerating module and a secondary refrigerating module, the primary refrigerating module and the secondary refrigerating module each comprising a condenser, an evaporator and a compressor. An air inlet pipe of the air module is connected to a hot side of a heat regenerator, the hot side of the heat regenerator is connected to the evaporators through ventilation pipes, the evaporators are connected to a cold side of the heat regenerator through ventilation pipes, and the cold side of the heat regenerator is connected to one of the condensers through a ventilation pipe.

Owner:GUANGZHOU SHINCCI ENERGY EQUIP CO LTD

Stirling cycle transducer for converting between thermal energy and mechanical energy

ActiveUS9394851B2Reduce mechanical stressStirling type enginesClosed-cycle gas positive displacement engine plantThermal energyReciprocating motion

The apparatus includes a housing, a compression chamber disposed in the housing and having at least a first interface operable to vary a volume of the compression chamber, an expansion chamber disposed in the housing and having a second interface operable to vary a volume of at least the expansion chamber, and a thermal regenerator in fluid communication with each of the compression chamber and the expansion chamber. The thermal regenerator is operable to alternatively receive thermal energy from gas flowing in a first direction through the regenerator and to deliver the thermal energy to gas flowing in a direction opposite to the first direction through the regenerator. The compression chamber, the expansion chamber, and the regenerator together define a working volume for containing a pressurized working gas. Each of the first and second interfaces are configured for reciprocating motion in a direction aligned with a transducer axis, the reciprocating motion being operable to cause a periodic exchange of working gas between the expansion and the compression chambers. In one aspect, at least one of the first and second interfaces includes a resilient diaphragm, and a cylindrical tube spring coupled between the diaphragm and the housing, the tube spring being configured to elastically deform in a direction generally aligned with the transducer axis in response to forces imparted on the tube spring by the diaphragm to cause the at least one of the first and second interfaces to have a desired natural frequency. In another aspect the apparatus includes a first heat exchanger in communication with the expansion chamber, a second heat exchanger in communication with the compression chamber, the thermal regenerator is disposed between the first and second heat exchangers, and each of the first and second heat exchangers are peripherally disposed within the housing with respect to the transducer axis and configured to receive working gas flowing to or from the respective chambers and to redirect the working gas flow through the regenerator.

Owner:ETALIM

Carbon dioxide trapping system based on phase change absorbent

ActiveCN114452779ALower capture costsIncrease Absorbent LoadDispersed particle separationAir quality improvementEngineeringPower apparatus

The carbon dioxide trapping system based on the phase change absorbent comprises an absorption tower, a phase splitter, a first-class power device, a heat exchange regenerator, a heat pump and a plurality of second-class power devices, and a mixed absorbent outlet of the absorption tower is connected with an absorbent inlet of the phase splitter through one second-class power device. A lean-phase absorbent outlet of the phase splitter is connected with a mixed absorbent inlet of the absorption tower through a second-class power device, a rich-phase absorbent outlet of the phase splitter is connected with a rich-phase absorbent inlet of the heat exchange regenerator through a first-class power device, and a regenerated absorbent outlet of the heat exchange regenerator is connected with a first inlet of the heat pump; a first outlet of the heat pump is connected with a mixed absorbent inlet of the absorption tower, a heat exchange medium outlet of the heat exchange regenerator is connected with a second inlet of the heat pump, a second outlet of the heat pump is connected with a heat exchange medium inlet of the heat exchange regenerator through a second-class power device, and the heat exchange regenerator comprises a gas exhaust port. And the heat exchanger is used for discharging carbon dioxide desorbed from the heat exchange regenerator.

Owner:TSINGHUA UNIV

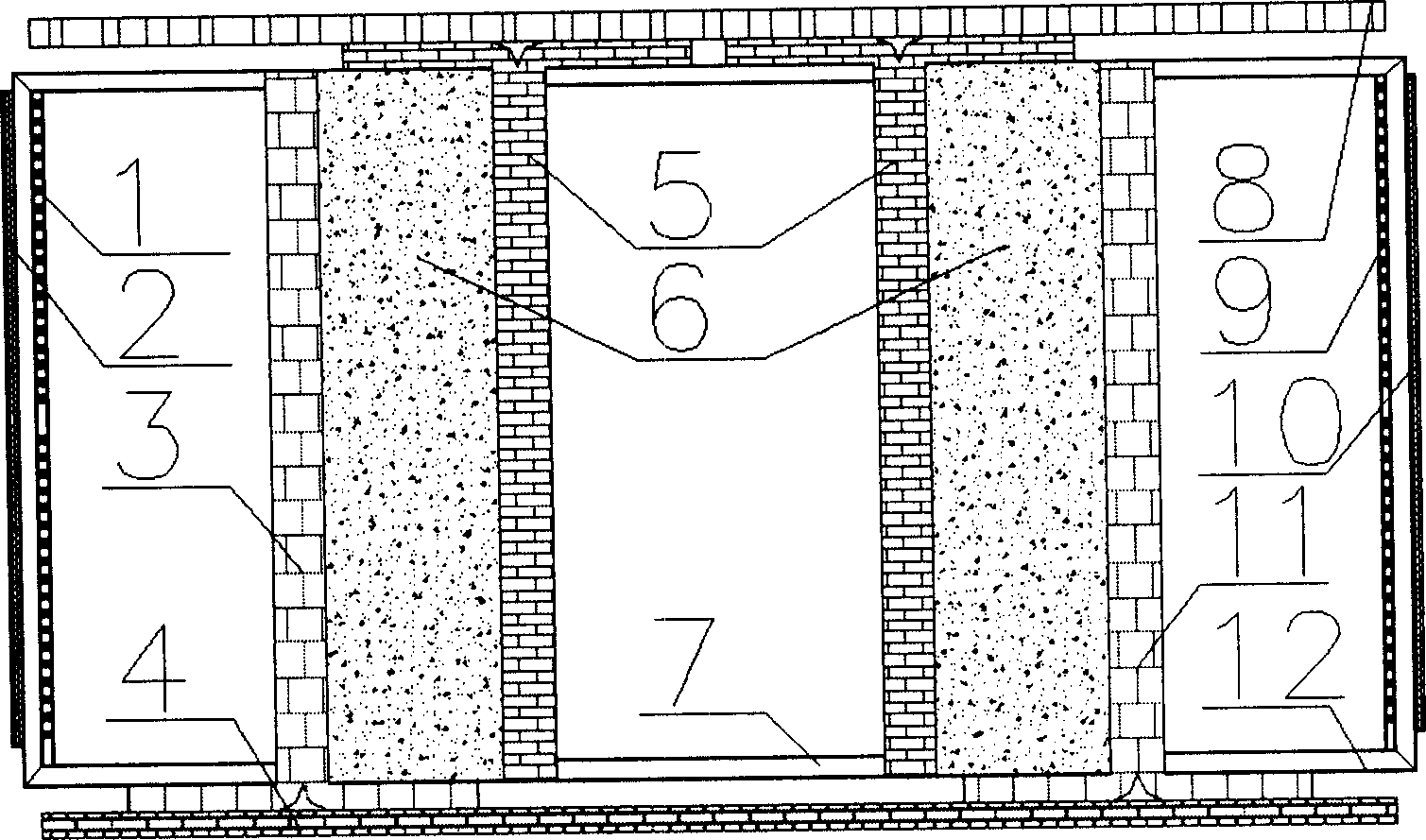

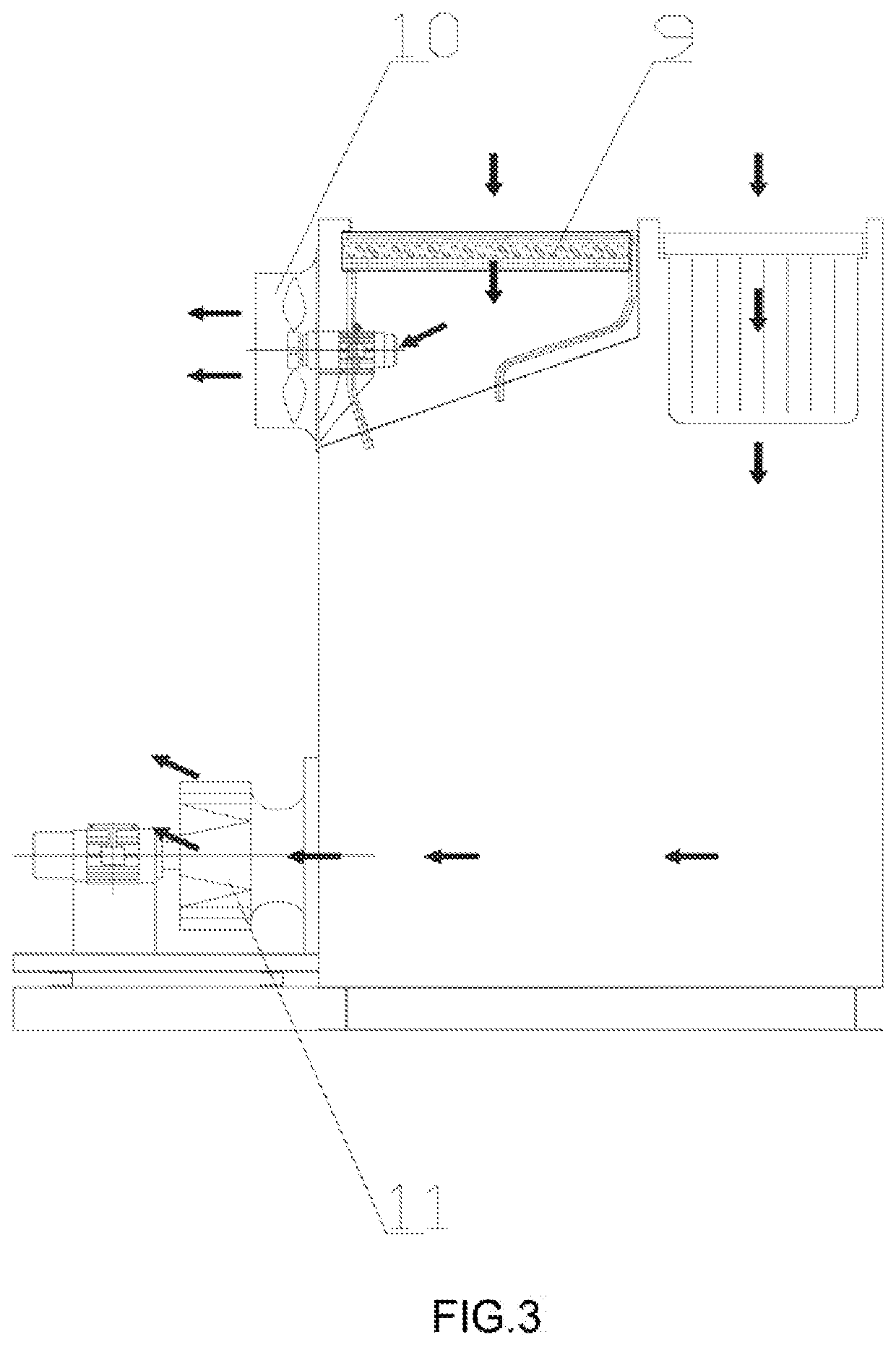

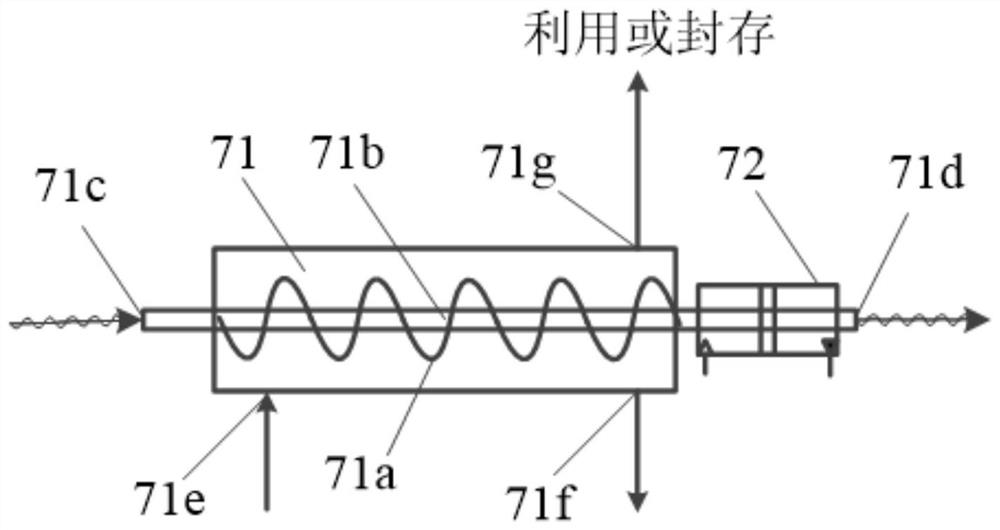

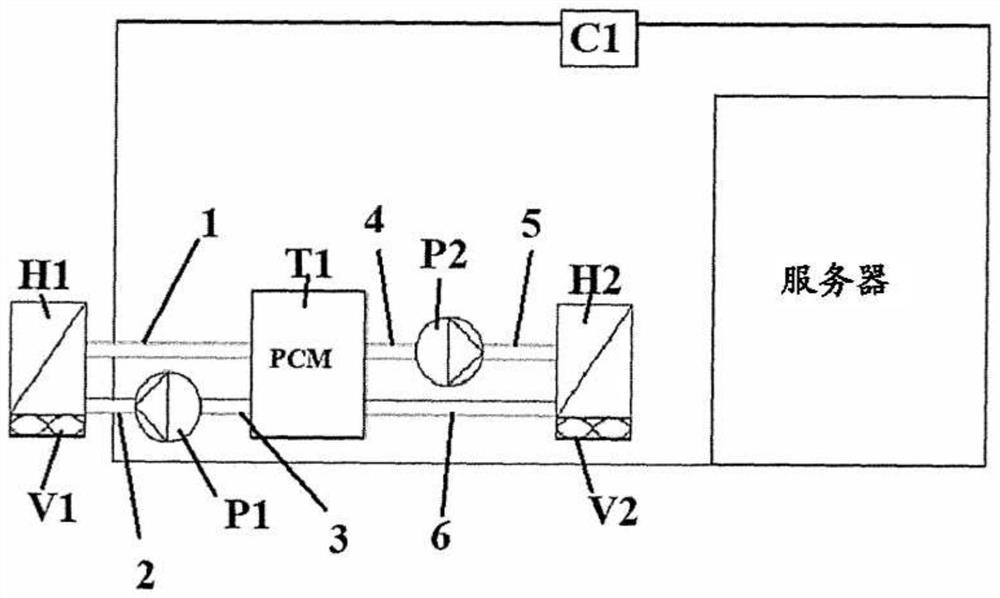

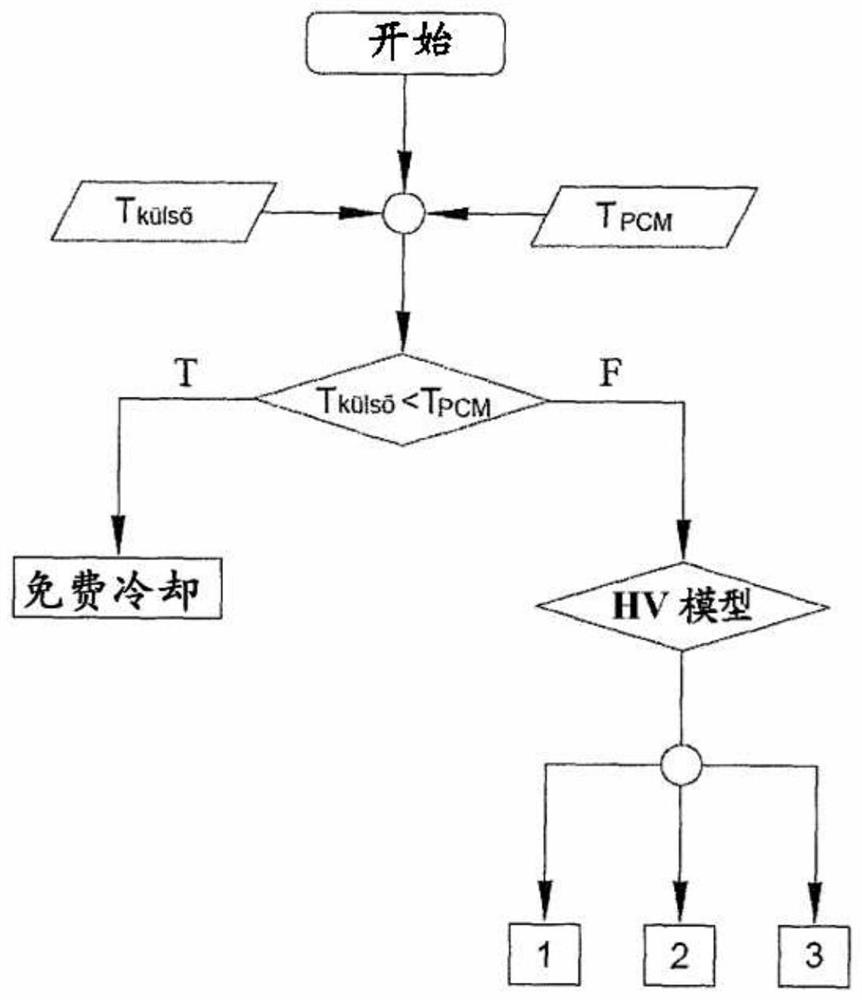

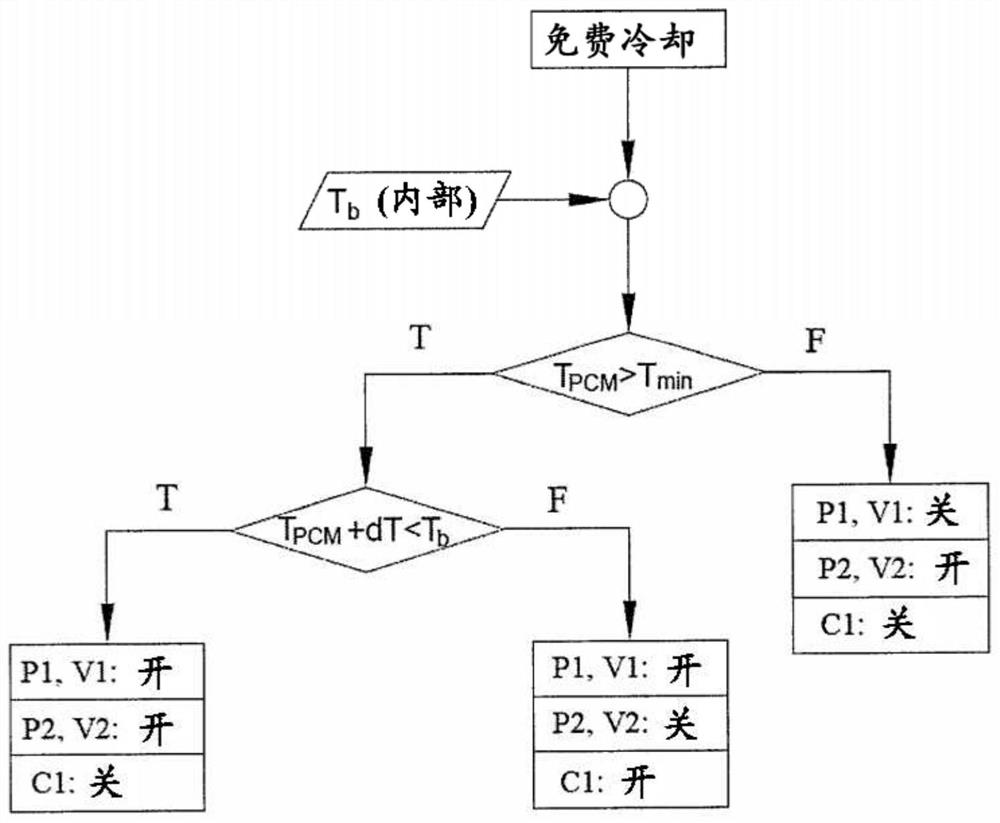

A system and an application for the regulation of temperature in a server room

The object of the invention is a system for regulating the temperature of particularly a server room, where the premises are equipped with an air-conditioning unit. The object of the invention, furthermore, is an application intended to operate the foregoing system, where an external primary circuit, an internal secondary circuit and an air- conditioning unit is operated during the operation of the system. The system according to the invention is characterized in that it furthermore includes a cooling array complete with a thermal regenerator that includes a cooling array complete with a thermal regenerator (T1) that includes an external primary circuit and an internal secondary circuit; where the external primary circuit is primed with a primary transmitting medium which may be circulated with a first fluid machinery, expediently a primary pump (P1), and passes through a primary heat exchanger (HI) unit located outside the premises; the internal secondary circuit is primed with a secondary transmitting medium which may be circulated with a second fluid machinery, expediently a secondary pump (P2), and passes through a secondary heat exchanger (H2) unit located inside the premises; and the external primary circuit and the internal secondary circuit can be controlled independently of each other, by a model suitable for control. The application according to the invention is characterized in that during the operation of the system, the following operating modes alternate: free cooling, case 1 according to the HV model, case 2 according to the HV model or case 3 according to the HV model.

Owner:换热器有限公司

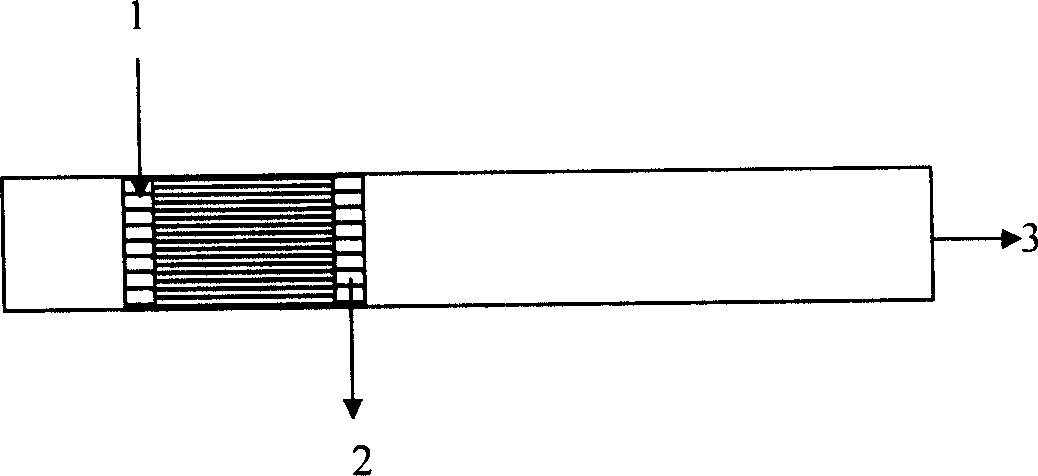

A method for reducing axial heat conduction of regenerator regenerator material of regenerative cryogenic refrigerator

InactiveCN101762119BReduce axial heat conductionThe heat exchange effect is sufficientSuperheatersRecovery methodWorking fluid

The invention relates to a method for reducing the axial heat conduction of a regenerator cold storage material by a regenerative low temperature refrigerator. In this method, when filling the cold storage material of the regenerator of the refrigerator, the thermal barrier made of the heat insulating material is put into the regenerator cylinder according to a certain interval distance, and the cold storage material of the regenerator is divided into several sections that are thermally disconnected. There are even and densely distributed small holes in the middle of the blocker, which does not affect the reciprocating flow of the working medium in the regenerator, and the small holes are arranged locally and regularly, which is beneficial to the heat exchange between the working medium and the cold storage material. The thermal resistance of the thermal isolator is more than 40 times that of the thermal storage material of the same thickness of the regenerator, but it has little effect on the thermal efficiency of the regenerator. The invention effectively reduces the axial heat conduction of the regenerator of the refrigerator, and the directional flow path of the working medium gas is unobstructed without gas retention, thereby improving the effective cooling capacity and efficiency of the refrigerator. This method can be applied to various regenerative cryogenic refrigerators.

Owner:WUXI HONGRUI AEROSPACE MECHANICAL & ELECTRICAL EQUIP CO LTD

Mixed working medium deep-freezing adsorption refrigerating device

InactiveCN100392332CImprove efficiencySimple structureClimate change adaptationEnergy efficient heating/coolingAdsorption refrigerationDesorption

Present invention discloses a mixing working medium deep refrigeration deep refrigeration adsorption refrigerator. It in turn connected first sorption / desorption unit, second sorption / desorption unit, condensator, constituent element separation module, second throttling set, second thermal regenerator, first thermal regenerator, first throttling set and evaporator, solid sorbent installed in first sorption / desorption unit and second sorption / desorption unit. Said invention applies self overlapping mixing working medium refrigerator principle to adsorption refrigeration system to fully utilize different kinds of high low temperature waste heat low temperature waste heat low temperature waste heat, to simplify tradition overlapping type adsorption refrigeration system realizing -60 to -200 degree centigrade deep refrigeration with simple structure, reliable performance, and high efficiency.

Owner:ZHEJIANG UNIV

Solar energy multi-stage solution reclaimer and method

InactiveCN100549563CRegenerator successfully realizes solar photothermal conversionRealize light-to-heat conversionSolar heat devicesClimate change adaptationThermodynamicsEngineering

The solar energy multi-stage solution regeneration device and method provide a new solar energy solution regeneration device for two-stage regeneration of the solution for the solar solution dehumidification evaporation cooling air-conditioning system. On the basis of constructing the primary and secondary solar heat collector / regenerator, the dilute solution is regenerated in the primary solar heat collector / regenerator by directly introducing outdoor air; The air is drier air that has been dehumidified by the air preconditioner, so as to achieve the function of further regeneration of the solution. The device is composed of primary and secondary solar heat collectors / regenerators, air preconditioners, solution heat exchangers and other main components. The device combines traditional heat collector / regenerator and single-stage air pretreatment heat collector / regenerator in one, so as to improve the regeneration performance of solar solution regenerator, especially suitable for solution dehumidification and cooling system of solution dehumidification and cooling system in summer high humidity in southern my country regeneration.

Owner:JIANGSU FOCUS NEW ENERGY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com