Minitype thermoacoustic refrigerator module device

A thermo-acoustic refrigeration and micro technology, applied in refrigerators, refrigeration and liquefaction, gas cycle refrigerators, etc., to achieve high refrigeration efficiency, simple structure, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

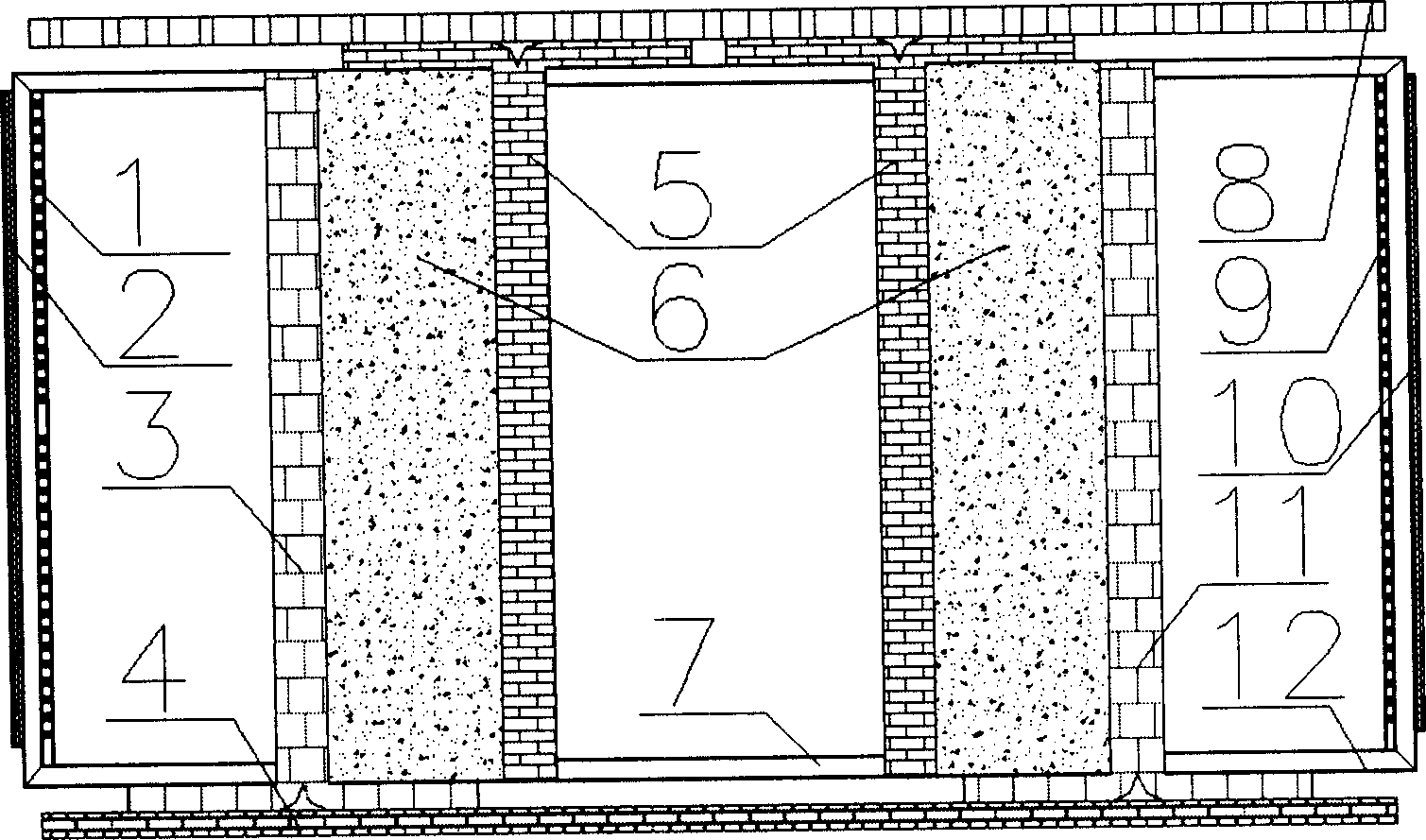

[0045] see figure 2 , a schematic diagram of the first structural scheme of the micro-thermoacoustic refrigeration module of the present invention, the refrigeration module is an acoustic refrigeration module driven by a micro-coil array membrane. The outer dimension of the present invention is 4.8×8×16mm, the total thickness direction is 4.8mm, and the effective thickness of the module is 4mm. The front end drives the film coil 1, the front permanent magnet film 2, the hot end heat exchanger 3, the hot end heat exchanger extension surface 4, the cold end heat exchanger 5, the regenerator 6, the skeleton 7, and the cold end heat exchanger extension Surface 8, back-end film coil 9, back-end permanent magnet film 10, hot-end heat exchanger 11, heat-insulating film 12 and other parts and suitable resonant cavities.

[0046] figure 2 Two sets of regenerators 6, corresponding cold-end heat exchangers 5 and hot-end heat exchangers 3 are arranged in the center. There are two laye...

specific Embodiment 2

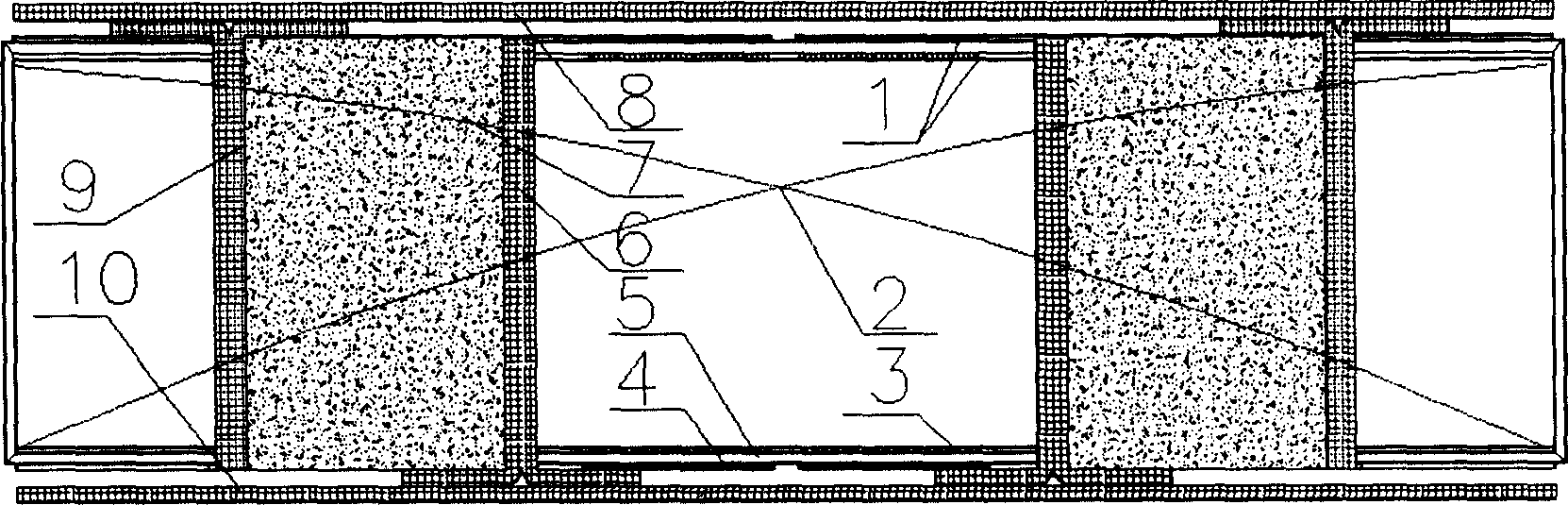

[0048] see image 3 , the second structural scheme of the miniature thermoacoustic refrigeration module composed of planar membrane arrangement of the present invention. The outer dimension of the refrigeration module of the present invention is 4.8×8×16mm, the total thickness direction is 4.8mm, and the effective thickness of the module is 4mm. Including front-end driving membrane assembly 1, rear-end membrane (planar coil) 3, cold-end permanent magnet material membrane 4, skeleton 5, cold-end heat exchanger 6, regenerator 7, hot-end heat exchanger extension surface 8, hot-end Heat exchanger 9, cold-end heat exchanger expansion surface 10 and other parts are formed, certainly also have annexes such as auxiliary insulation film. image 3 The 2 in represents the waveform line, that is, the acoustic waveform line when the thermoacoustic refrigeration module is working.

[0049] The overall dimensions of the micro-thermoacoustic refrigeration module of the present invention are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimensions | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com