Hydraulic herringbone steel dam

A technology of hydraulic pressure and beam steel, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of high power of the driving device, sensitive foundation deformation, and limited use conditions, etc., and achieves fast dam erection, simple structure, and long life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

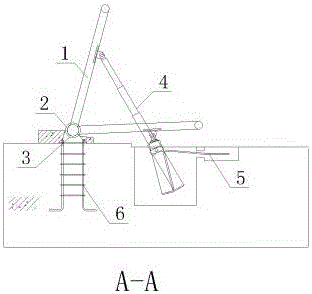

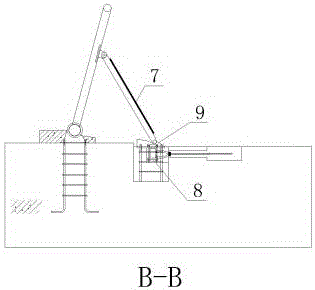

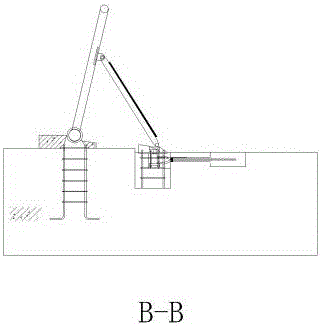

[0024] In order to understand the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0025] see figure 1 — Figure 7 The hydraulic herringbone steel dam is composed of several water-blocking panels 1 according to the width of the water-blocking surface of the river, and each water-blocking panel 1 is firmly connected to the dam foundation by the bottom shaft 2 through the hinge support 3; The back of the water panel 1 is only connected to a large hydraulic cylinder 4 and a support system. By controlling the expansion and contraction of the large hydraulic cylinder 4 and the length of the expansion and contraction, the rotation of the water blocking panel 1 is driven, thereby realizing dam erection, dam release and adjustment of water blocking Height; when the water blocking panel 1 reaches the design support position, the support system will play a role, forming a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com