Flexible flat cable for high-speed signal transmission

A high-speed signal transmission, flexible flat technology, used in flat/ribbon cables, communication cables, flexible cables, etc., can solve problems such as deterioration, poor product attenuation, inability to transmit 10Gbps high-speed differential signals, etc., to improve crosstalk performance, thin thickness, the effect of increasing the ground signal layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

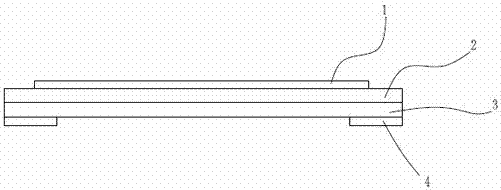

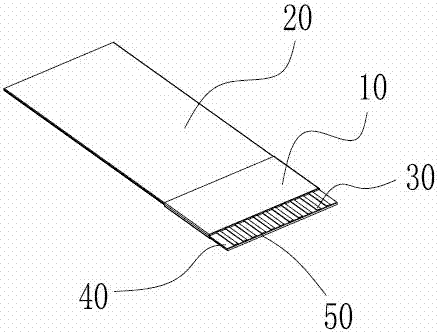

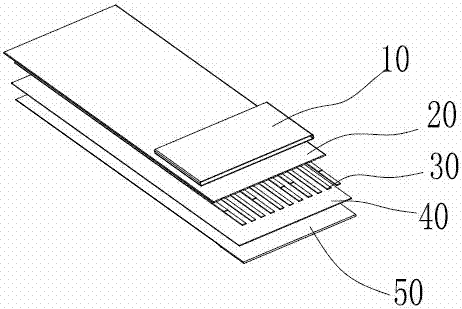

[0018] like figure 2 , 3 As shown, a flexible flat cable for transmitting high-speed signals, the flexible flat cable includes: a ground signal layer 10, an upper insulating layer 20, a conductive wire layer 30, a lower insulating layer 40 and a reference plane layer 50, the The conductive wire layer 30 includes a plurality of conductors arranged in parallel at the same pitch, and the conductive wire layer 30 can be made into a trapezoidal, circular or rectangular shape as required; the upper insulating layer 20 and the lower insulating layer 40 are bonded on the conductive wire layer 30 And below and wrapping the conductive wire layer 30 in the middle, the upper insulating layer 20 and the lower insulating layer 40 use high-frequency insulating materials, such as TEF, so that the attenuation of the signal is smaller and the transmission is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com