A Method for Fabricating Two-Dimensional Flexible Light-Emitting Arrays Using Local Stress

A light-emitting array and local stress technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve problems such as the inability to control the light-emitting parts of devices, and achieve the effect of meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

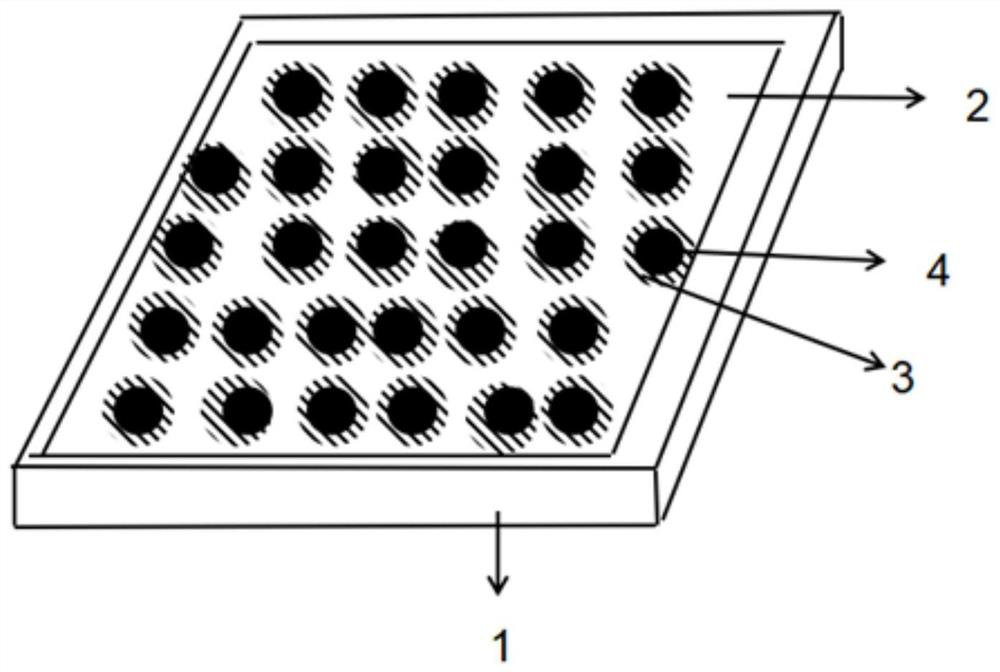

[0030] A method for preparing a two-dimensional flexible light-emitting array using local stress, comprising the following steps:

[0031] (1) Using flexible materials as the substrate;

[0032] (2) Depositing a layer of metal material on the substrate;

[0033] (3) carrying out microwave annealing to the substrate after depositing the metal material in step (2), so that the metal material forms metal islands on the substrate;

[0034] (4) Continue to transfer a layer of tungsten diselenide layer on the metal island formed in step (3), which is completed.

[0035] In this embodiment, in step (1), the flexible material is polyimide. In step (2), the metal material is gold with a thickness of 20-50nm. In step (3), the process conditions of microwave annealing are: microwave power 2000-5000 watts, annealing time 1-10 minutes. . In step (4), the thickness of the tungsten diselenide layer is two atomic layers.

Embodiment 2

[0037] Compared with Embodiment 1, most of them are the same, except that in this embodiment, the flexible material is polyethylene naphthalate.

Embodiment 3

[0039] Compared with Embodiment 1, most of them are the same, except that in this embodiment, the flexible material is polyethylene terephthalate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com