Nuclear power 1E-grade K1-type thermal shrinkage cable accessory material and preparation method thereof

A heat-shrinkable cable and nuclear power technology, applied in the direction of nuclear power generation, greenhouse gas reduction, climate sustainability, etc., can solve the problems of heat-shrinkable cable accessories, etc., achieve significant toughening effect, improve thermal stability, and improve dispersion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

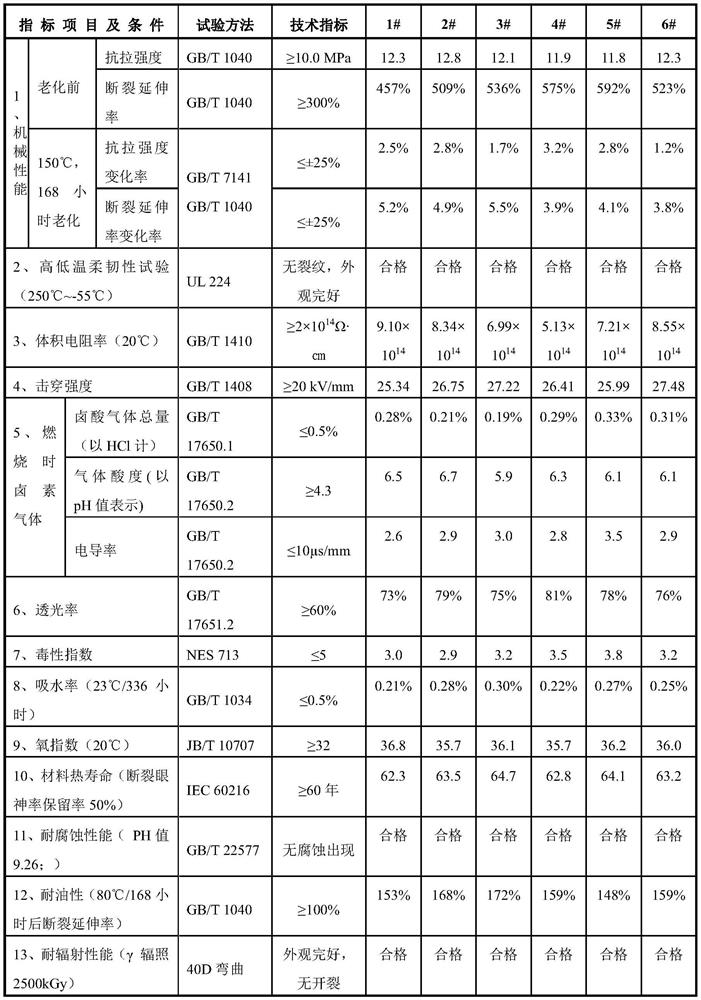

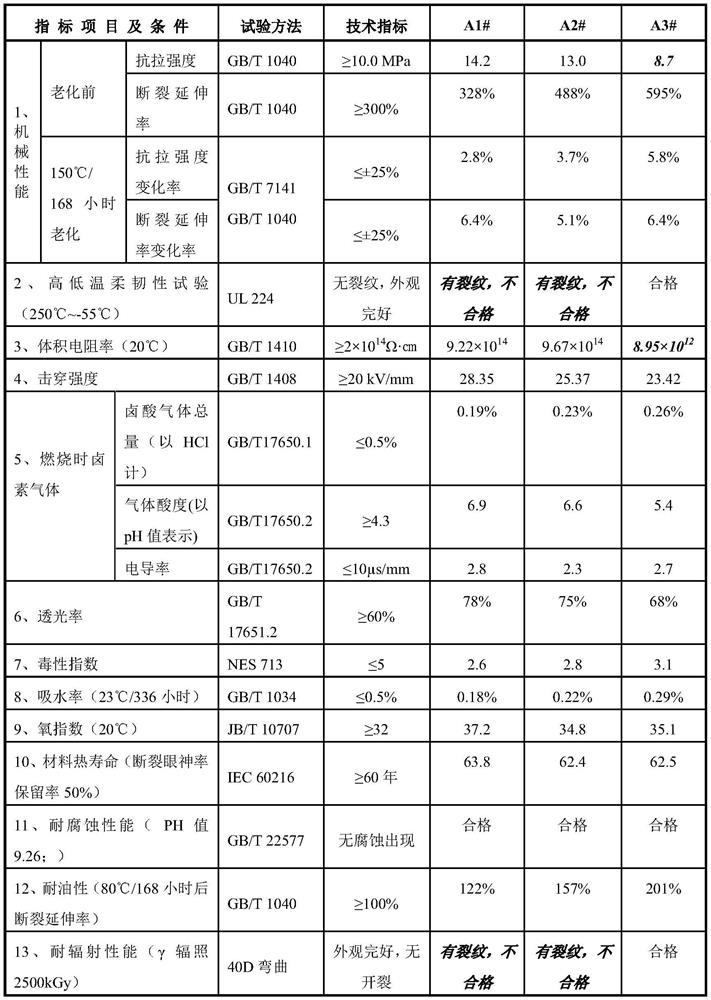

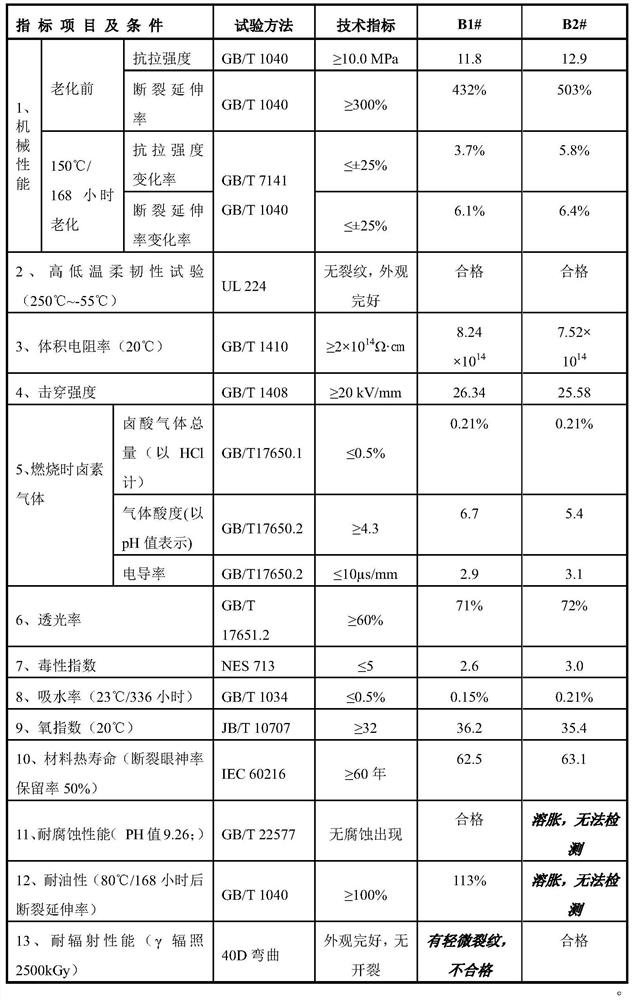

Examples

Embodiment 1

[0025] 120g LDPE18D0, 120g POE810, 5g antioxidant 1010, 2.5g antioxidant DLTP, 2.5g antioxidant 168, 90g aluminum hydroxide, 90g magnesium hydroxide, 60g lignin-based flame retardant, 10g methyl mercaptan Tin heat stabilizer is added in the internal mixer, 10g carbon black N330, 3g methyl vinyl phenyl silicone rubber raw rubber (30wt% of its phenyl content, 0.5wt% vinyl content, molecular weight 350,000 g / mol), 20g Methyl-β-nitrile ethyl siloxane rubber (the β-nitrile ethyl siloxane content is 20wt%, vinyl content is 0.15wt%, molecular weight is 600,000 g / mol), 15g sensitizer, mixed at 135°C In 30 minutes, Hualong No. 1 Class 1E K1 heat-shrinkable cable accessory materials were obtained. This material was pressed into tablets with a hydraulic press to prepare samples, and then irradiated with an electron accelerator at 150KGy to obtain sample 1 # .

Embodiment 2

[0027] Heat 140g LDPE18D0, 120g POE8150, 6g antioxidant 1010, 3g antioxidant DLTP, 3g antioxidant 168, 100g aluminum hydroxide, 100g magnesium hydroxide, 70g lignin-based flame retardant, 12g methyl tin mercaptide Stabilizer, 12g carbon black N330, 2g methyl vinyl phenyl silicone rubber raw rubber (30wt% phenyl content, 0.5wt% vinyl content, molecular weight 350,000 g / mol), 18g methyl-β-nitrile acetonitrile Silicone rubber (its β-nitrile ethylsiloxane content is 20wt%, vinyl content is 0.15wt%, molecular weight is 600,000 g / mol), 18g sensitizer is added in the internal mixer, and mixed at 135°C for 28 Minutes, get Hualong No. 1E grade K1 heat shrinkable cable accessories materials. This material is pressed into tablets with a hydraulic press to prepare samples, and then irradiated with an electron accelerator at 160KGy to obtain sample 2 # .

Embodiment 3

[0029] Heat 130g LDPELD605, 150g POE875, 6g antioxidant 1010, 3g antioxidant DLTP, 3g antioxidant 168, 100g aluminum hydroxide, 100g magnesium hydroxide, 70g lignin-based flame retardant, 12g methyl tin mercaptide Stabilizer, 12g carbon black N330, 3g methyl vinyl phenyl silicone rubber raw rubber (its phenyl content is 30wt%, vinyl content is 0.5wt%, molecular weight is 350,000 g / mol), 20g methyl-β-nitrile acetonitrile Silicone rubber (its β-nitrile ethylsiloxane content is 20wt%, vinyl content is 0.15wt%, molecular weight is 600,000 g / mol), 18g of sensitizer is added to the internal mixer, and mixed for 31 hours at 135°C Minutes, get Hualong No. 1E class K1 heat-shrinkable cable accessory material masterbatch. This material was pressed into tablets with a hydraulic press to prepare samples, and then irradiated with an electron accelerator at 160KGy to obtain sample 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com