Modularized cabinet

A modular and chassis technology, applied to stackable modules, support structure installation, electrical equipment construction parts, etc., can solve the problem of electromagnetic compatibility performance and heat dissipation performance, quick disassembly performance rejection, and module vibration and shock resistance. Strong and difficult to replace modules in the chassis, etc., to achieve the effect of improving rapid response capability, reducing professional skill requirements, and improving maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

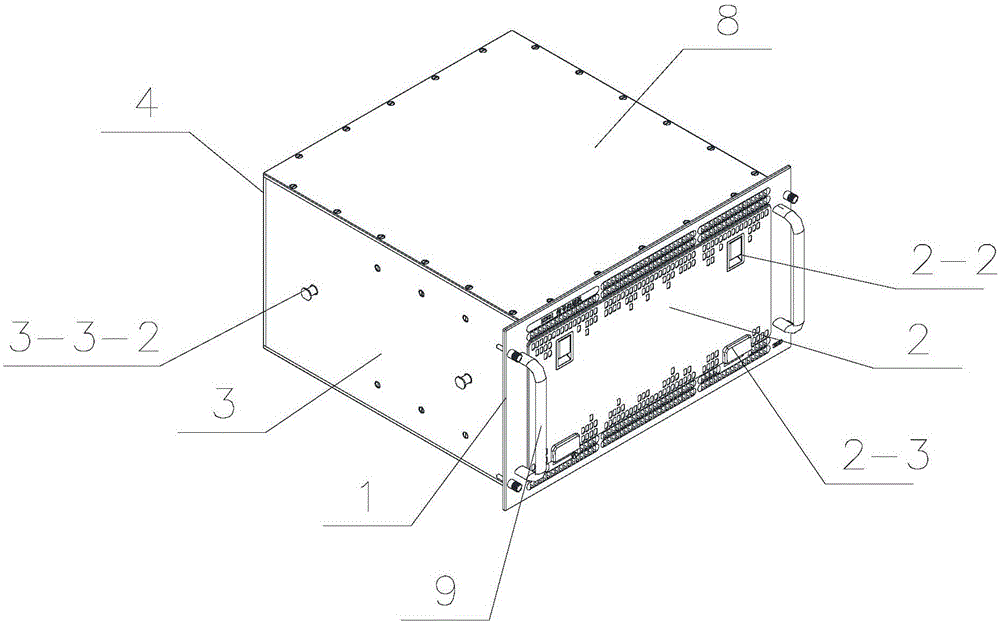

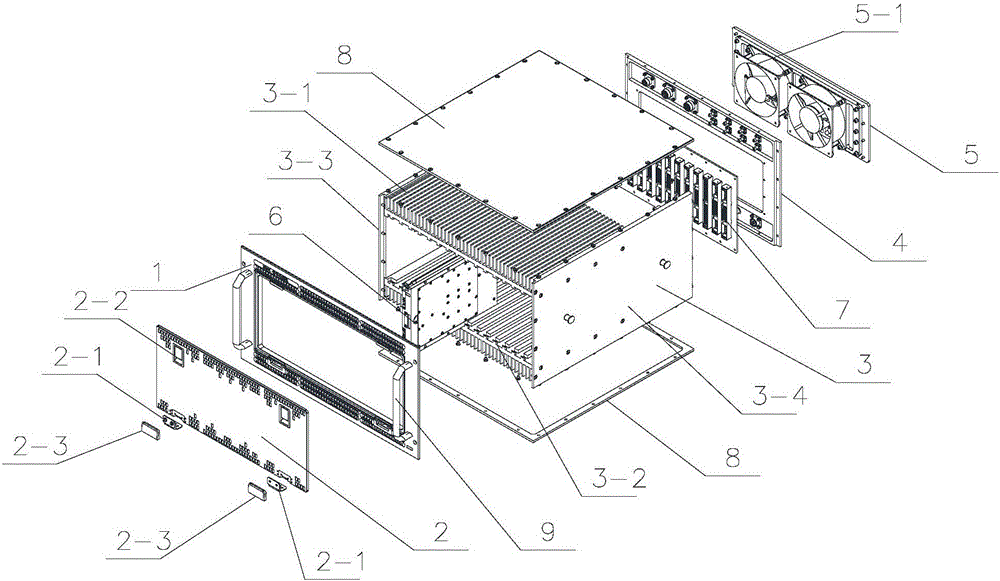

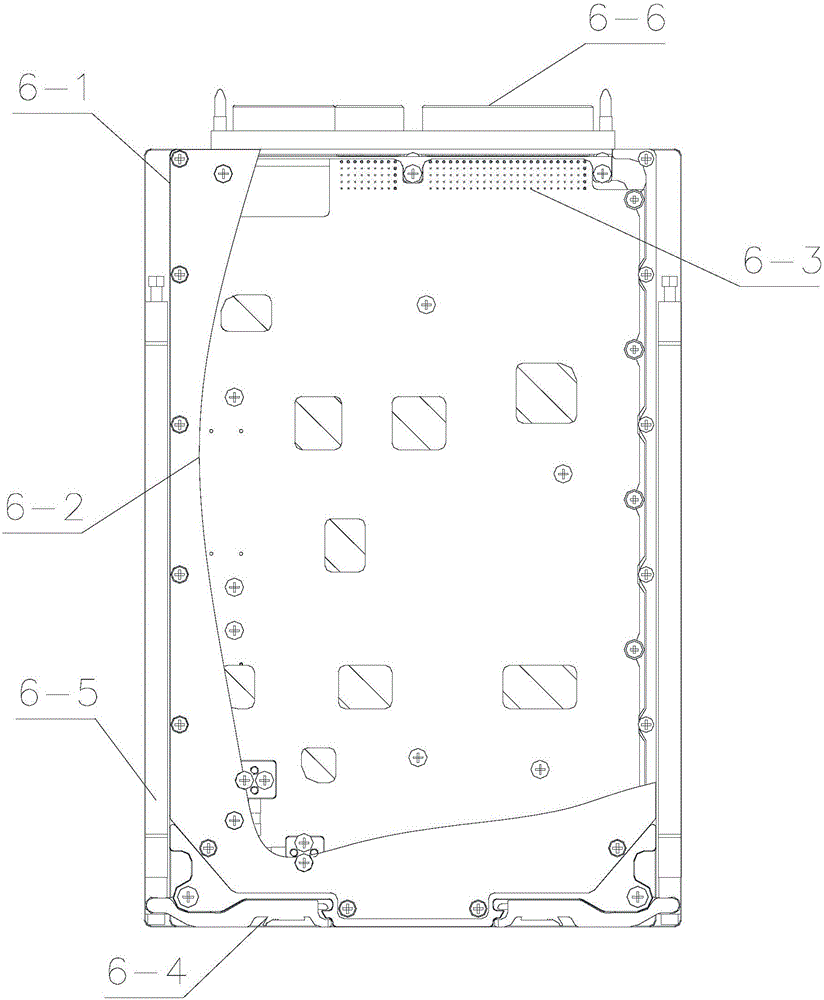

[0050] (1) If figure 1 , figure 2 , image 3 Shown is an embodiment of the present invention. In this embodiment, the 19-inch standard chassis is transformed into a type that can realize quick plugging and unplugging capabilities, quick module removal capabilities, radio frequency blind insertion capabilities, high heat dissipation capabilities, high electromagnetic shielding capabilities, and anti-corrosion. It is a 19-inch standard high-performance modular chassis with strong vibration and shock resistance, strong anti-salt spray ability, and independent fan components.

[0051] The entire chassis adopts a modular design idea, and the functional modules 6, front panel 1, rear panel 4, independent fan assembly 5, guide rail support, cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com