A fermentation accelerator for preparing feed from air-dried bagasse

A fermentation accelerator, bagasse technology, applied to bacteria, animal feed, animal feed and other directions used in food preparation, can solve the problem of restricting the development of lignocellulosic biomass conversion feed, low degradation rate of lignocellulosic enzymes, and promoting fermentation. It can reduce the loss, have good adaptability, and have strong acid-producing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] S3, the preparation of fermentation accelerator: after each bacteria reaches the corresponding effective viable count, mix by volume ratio of 1:1:1:3-5 to make fermentation accelerator;

[0030] S4. Preparation of fermentation material: use MRS-S medium to adjust the moisture content of air-dried bagasse crushed material to 65-75%, add 0.5% urea, 1% ammonium sulfate, 8% sucrose by dry weight, stir evenly, and make fermentation material ;

[0031] S5. Anaerobic fermentation: The bacterial liquid of the fermentation promoter in S3 is evenly sprayed on the fermentation material in S4 according to the concentration ratio of 10%, stirred evenly, strictly compacted, sealed with three layers of plastic film, solid anaerobic at 33-37 ° C Fermentation promoters for the desired feeds can be prepared after 20 to 25 days of fermentation.

[0032] In this embodiment, the fermentation material can also be prepared by using air-dried bagasse and molasses alcohol waste mash. Specifica...

Embodiment 1

[0033]Embodiment 1, fermentation accelerator is prepared as follows:

[0034] 1) Inoculate Lactobacillus plantarum stored at -80°C into 100mL MRS-S medium at 37°C for anaerobic culture for 24 hours for activation, and then expand the culture with 10% of the inoculum;

[0035] 2) Inoculate Pediococcus lactis stored at -80°C into 100mL MRS-S medium at 37°C for anaerobic culture for 24 hours for activation, and then expand the culture with 10% of the inoculum;

[0036] 3) Inoculate Streptococcus faecalis stored at -80°C into 100Ml MRS-S medium at 37°C for anaerobic culture for 24 hours for activation, and then expand the culture with 10% of the inoculum;

[0037] 4) Inoculate Bacillus subtilis stored on a -4°C slant into 100mL LB medium, 37°C shake flask culture for 24 hours for activation, and then expand the culture with 10% of the inoculum;

[0038] 5) Preparation of fermentation accelerator: Lactobacillus plantarum, Pediococcus lactis, Streptococcus faecalis, mixed and prepa...

Embodiment 2

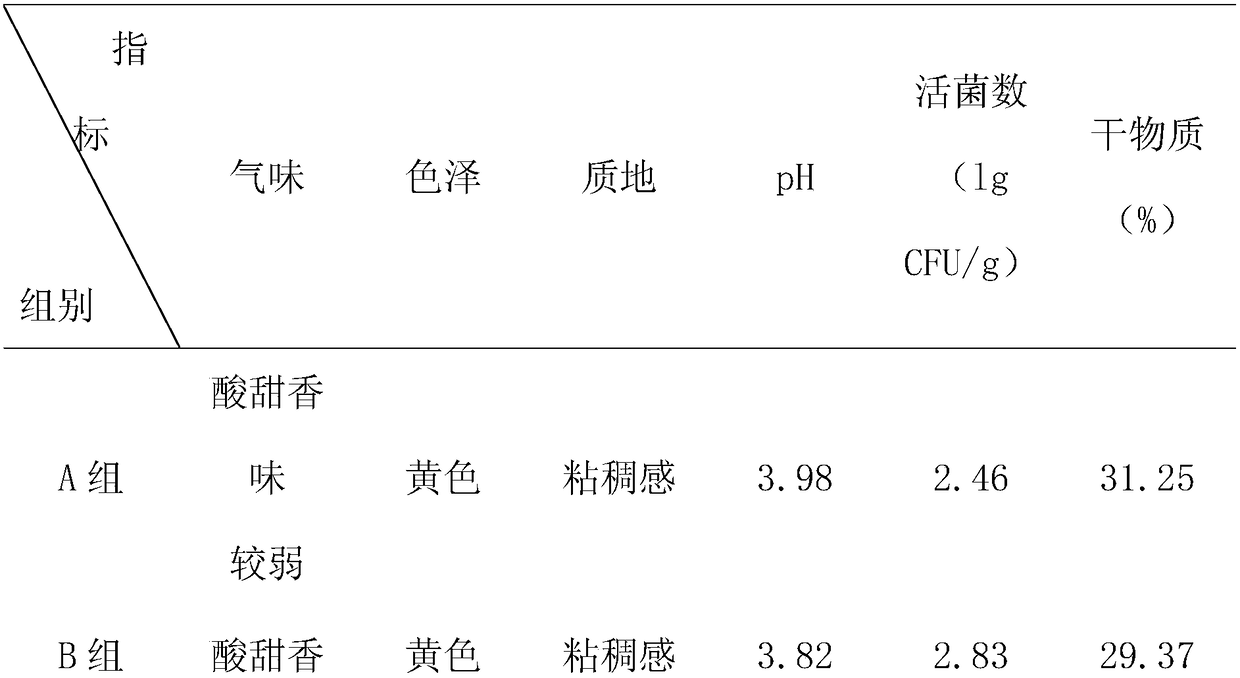

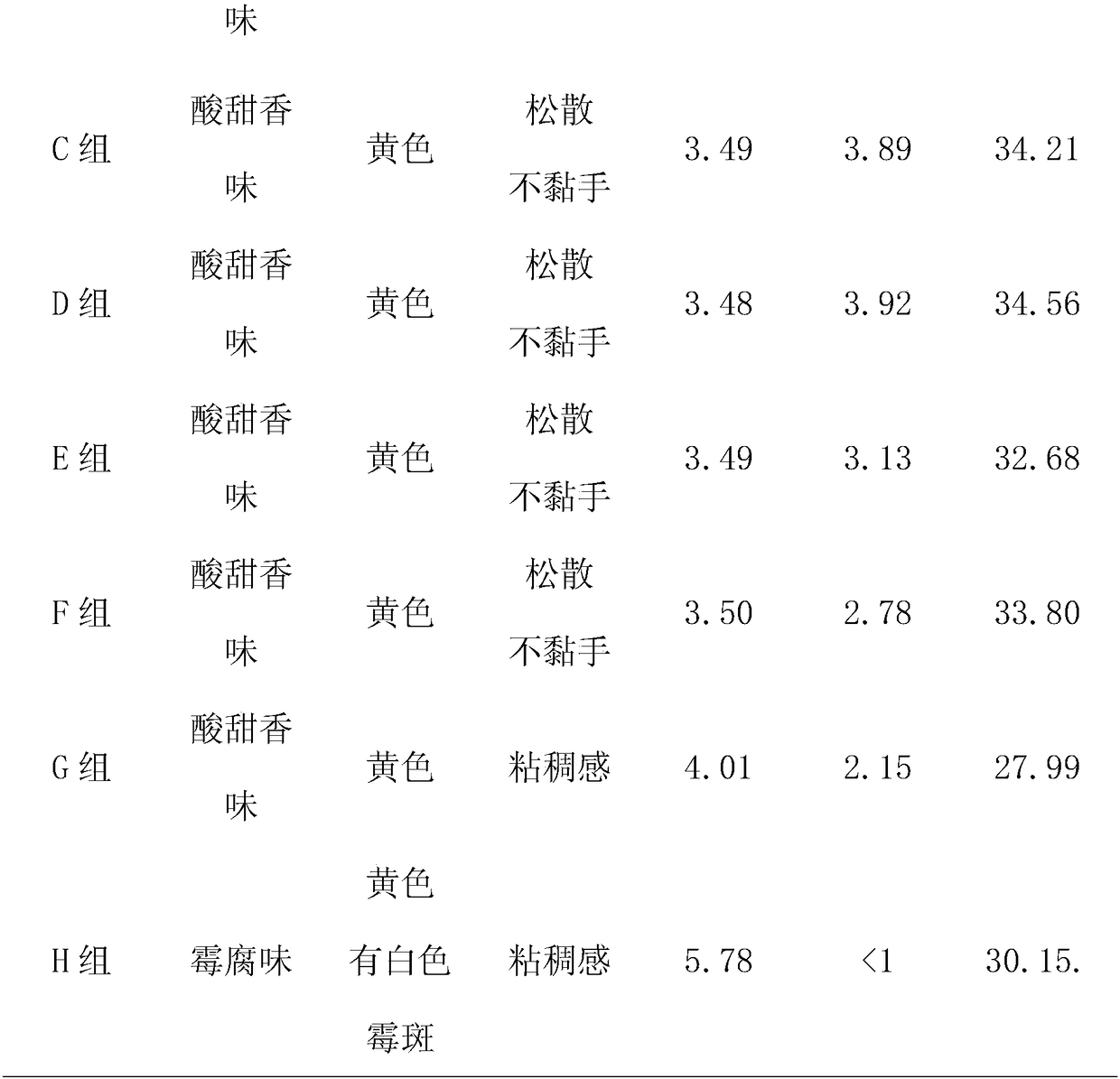

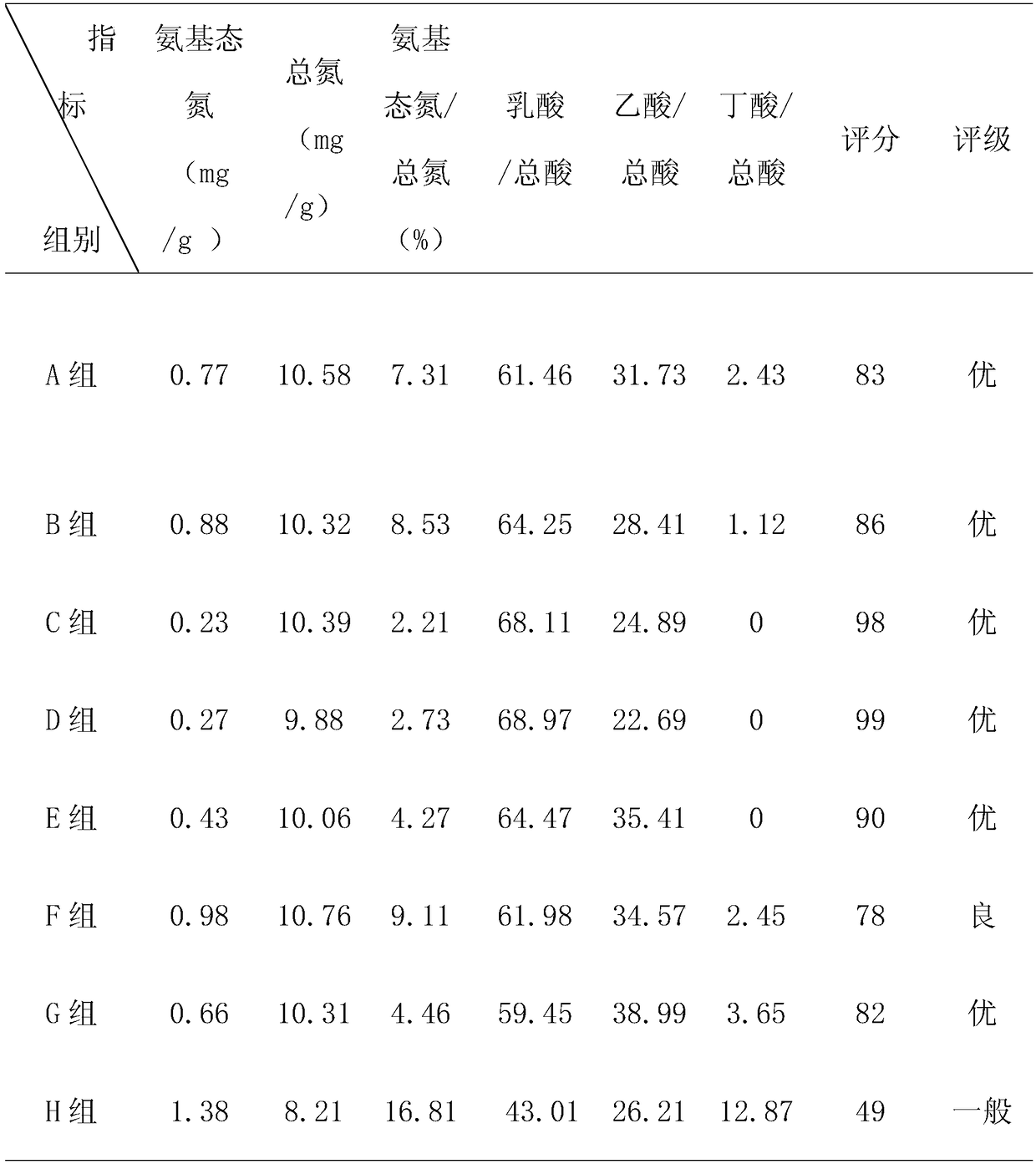

[0043] Embodiment 2 The influence of different lactic acid bacteria fermentation accelerators on the fermentation effect of air-dried bagasse

[0044] (1) prepare lactic acid bacteria fermentation accelerators A, B, C, D, E, F, G;

[0045] (2) the bagasse is air-dried and pulverized to 40 meshes;

[0046] (3) Load the bagasse pulverized material into a plastic bucket with a diameter of 30cm and a height of 40cm, adjust the moisture content of the air-dried bagasse pulverized material to 65-75% by using MRS-S medium, add 8% sucrose and 0.5% urea by dry weight , 1% ammonium sulfate, stir evenly, prepare 8 portions, spray fermentation accelerators A, B, C, D, E, F, G respectively, stir evenly, seal and compact with plastic film multiple times to ensure anaerobic environment, seal After 30 days of fermentation, open the sealing film and take samples; the uninoculated group is marked as H;

[0047] (4) Take 200g of each sample in this example A, B, C, D, E, F, G, and H for sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com