Anaerobic fermentation pre-desulfurization method and device

An anaerobic fermentation and anaerobic fermenter technology, which is applied in the field of anaerobic fermentation pre-desulfurization methods and devices, can solve the problems of high desulfurization cost, low gas production efficiency, instability, etc., so as to improve desulfurization efficiency, reduce desulfurization load, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

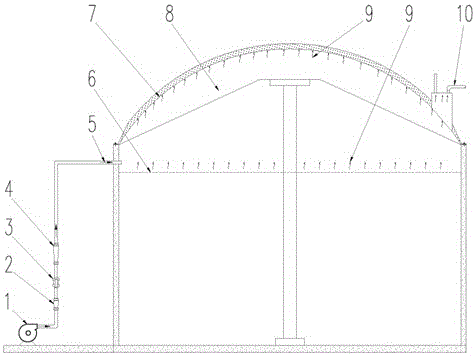

[0034] Such as figure 1 Shown in, the anaerobic fermentation pre-desulfurization method of the present invention, comprises the steps:

[0035] Step 1: extract the biogas sample in the anaerobic fermentation gas storage chamber 8 located on the top of the anaerobic fermentation tank;

[0036] Step 2: detecting the hydrogen sulfide content in the extracted biogas sample;

[0037] Step 3: According to the detected hydrogen sulfide content, when the hydrogen sulfide content is higher than 1000ppm, pass 3%-5% of the air produced in the fermentation tank into the anaerobic fermentation gas storage chamber (8), through the following reaction formula Perform a chemical reaction:

[0038] H2S + 2O2 = H2SO4

[0039] H2S + O22 = 2S + 2H2O

[0040] S + H2O + 1.5O22=H2SO4;

[0041] Step 4: After the chemical reactions in step 3 are fully reacted, re-extract the biogas sample in the anaerobic fermentation gas storage chamber 8, and detect the hydrogen sulfide content in the extracted ...

Embodiment 2

[0045] Such as figure 1 Shown in, the anaerobic fermentation pre-desulfurization method of the present invention, comprises the steps:

[0046] Step 1: extract the biogas sample in the anaerobic fermentation gas storage chamber 8 located on the top of the anaerobic fermentation tank;

[0047] Step 2: detecting the hydrogen sulfide content in the extracted biogas sample;

[0048] Step 3: According to the detected hydrogen sulfide content, when the hydrogen sulfide content is higher than 1000ppm, pass 3% of the air produced in the fermentation tank into the anaerobic fermentation gas storage chamber (8), and carry out the chemical reaction through the following reaction formula :

[0049] H2S + 2O2 = H2SO4

[0050] H2S + O22 = 2S + 2H2O

[0051] S + H2O + 1.5O22=H2SO4;

[0052] Step 4: After the chemical reactions in step 3 are fully reacted, re-extract the biogas sample in the anaerobic fermentation gas storage chamber 8, and detect the hydrogen sulfide content in the extr...

Embodiment 3

[0054] Such as figure 1 Shown in, the anaerobic fermentation pre-desulfurization method of the present invention, comprises the steps:

[0055] Step 1: extract the biogas sample in the anaerobic fermentation gas storage chamber 8 located on the top of the anaerobic fermentation tank;

[0056] Step 2: detecting the hydrogen sulfide content in the extracted biogas sample;

[0057] Step 3: According to the detected hydrogen sulfide content, when the hydrogen sulfide content is higher than 1000ppm, pass 5% of the air produced in the fermentation tank into the anaerobic fermentation gas storage chamber (8), and carry out the chemical reaction through the following reaction formula :

[0058] H2S + 2O2 = H2SO4

[0059] H2S + O22 = 2S + 2H2O

[0060] S + H2O + 1.5O22=H2SO4;

[0061] Step 4: After the chemical reactions in step 3 are fully reacted, re-extract the biogas sample in the anaerobic fermentation gas storage chamber 8, and detect the hydrogen sulfide content in the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com