Shielding cover frame and manufacturing process thereof

A manufacturing process and technology of shielding cover, applied to the field of shielding cover frame and its manufacturing process, can solve the problems of increasing mold maintenance cost, production efficiency, high frequency of use of spare parts, poor dimensional stability, etc., and achieve material strength enhancement and mold repair. Cost reduction and residual stress relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

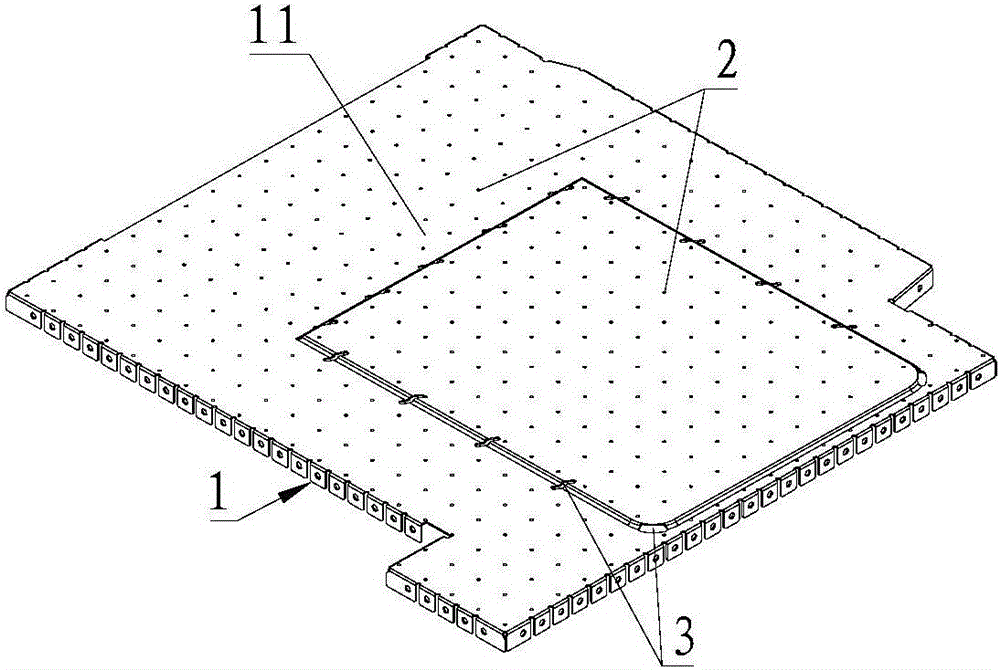

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

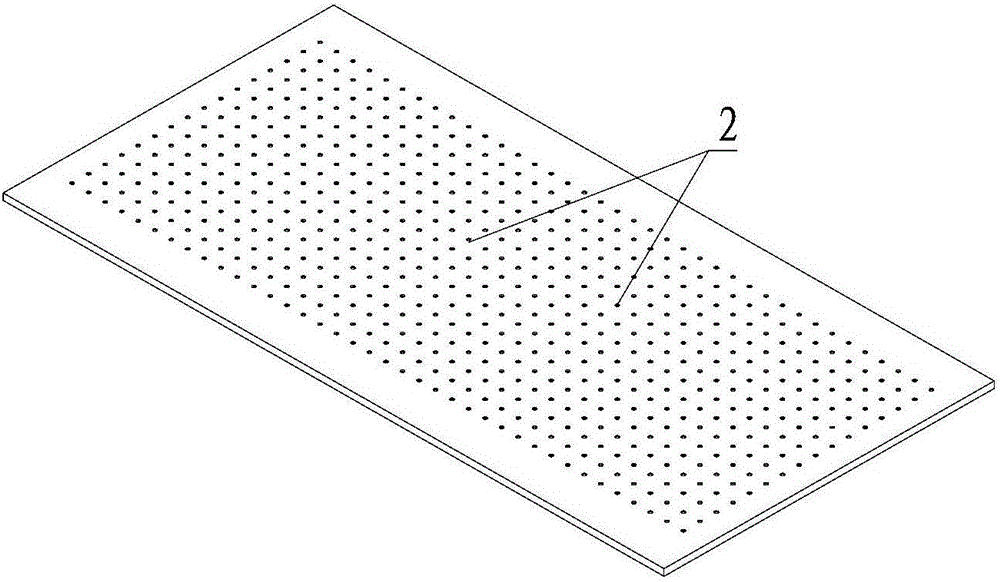

[0019] The most critical idea of the present invention is that: the present invention prints marking points 2 on the raw material tape to manufacture the body 1, and the shield frame with the depression or protrusion can effectively ensure the flatness.

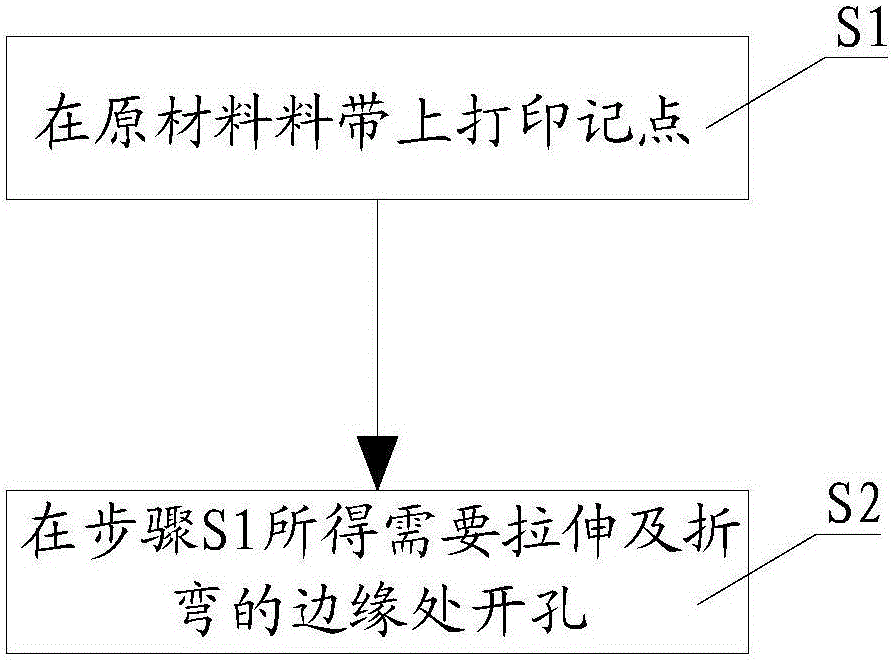

[0020] see figure 1 , the manufacturing process of the shielding case frame of the present invention comprises the following steps:

[0021] S1. Print marking points on the raw material tape, the marking points are depressions or protrusions arranged at intervals to prepare blanks;

[0022] S2. Open holes on the edge of the blank that needs to be stretched and bent.

[0023] It can be seen from the above description that the beneficial effect of the present invention lies in that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com