A water craft or flying craft having a propeller

A technology of propulsion and tools, applied in the direction of ship propulsion, propulsion components, power plant types, etc., can solve the problems of increasing the loss of pumping energy, affecting the control experience, reducing the propulsion force, etc., to improve propulsion efficiency, flexible operation, The effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

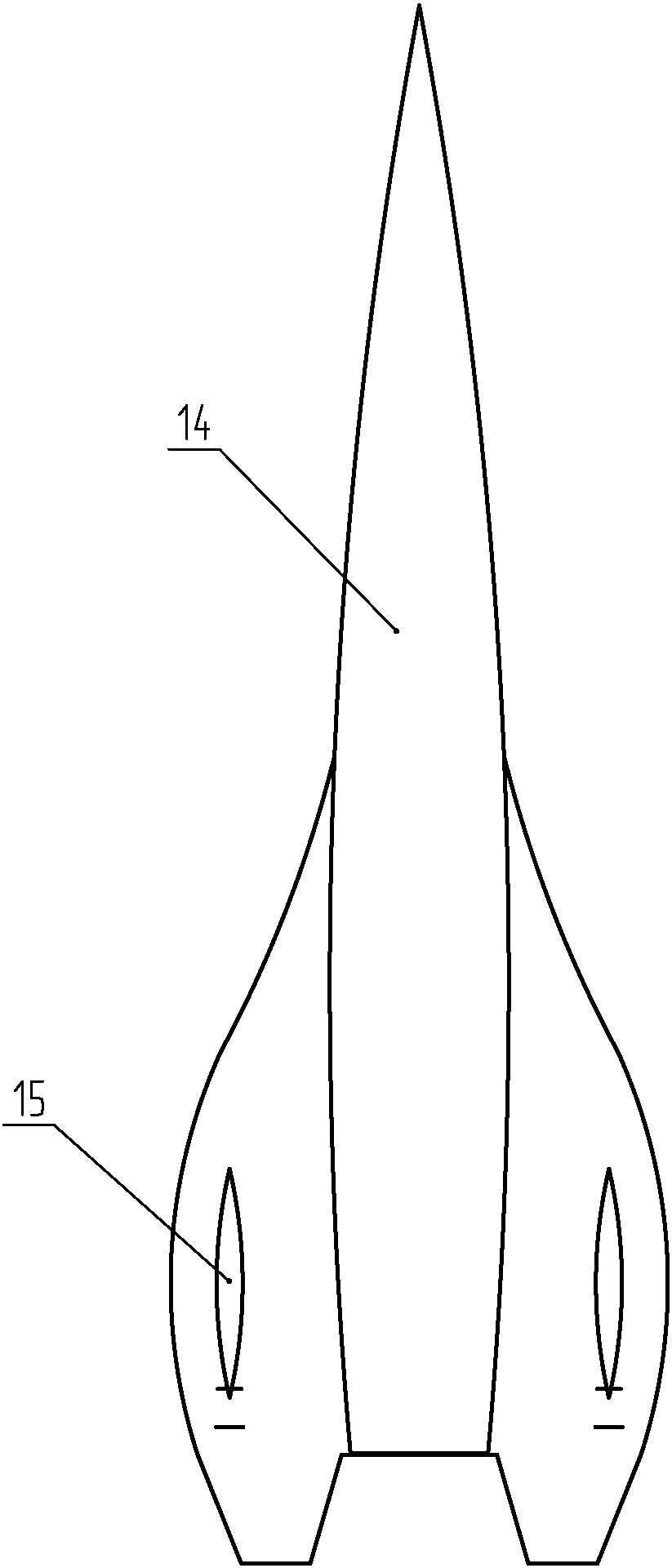

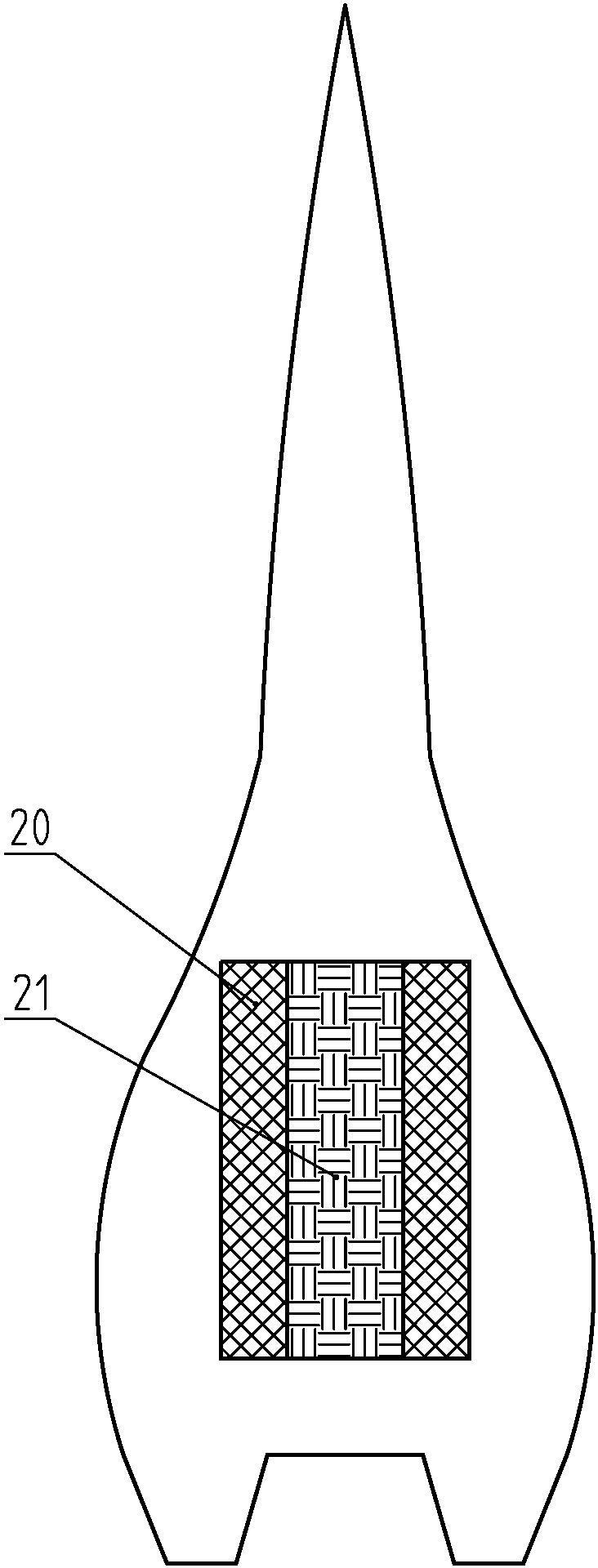

[0035] like Figures 1 to 6 As shown, a water tool with an improved thruster includes a tool body 14, two guide bodies 15, two propulsion devices, a control device, a control device, and a power supply device.

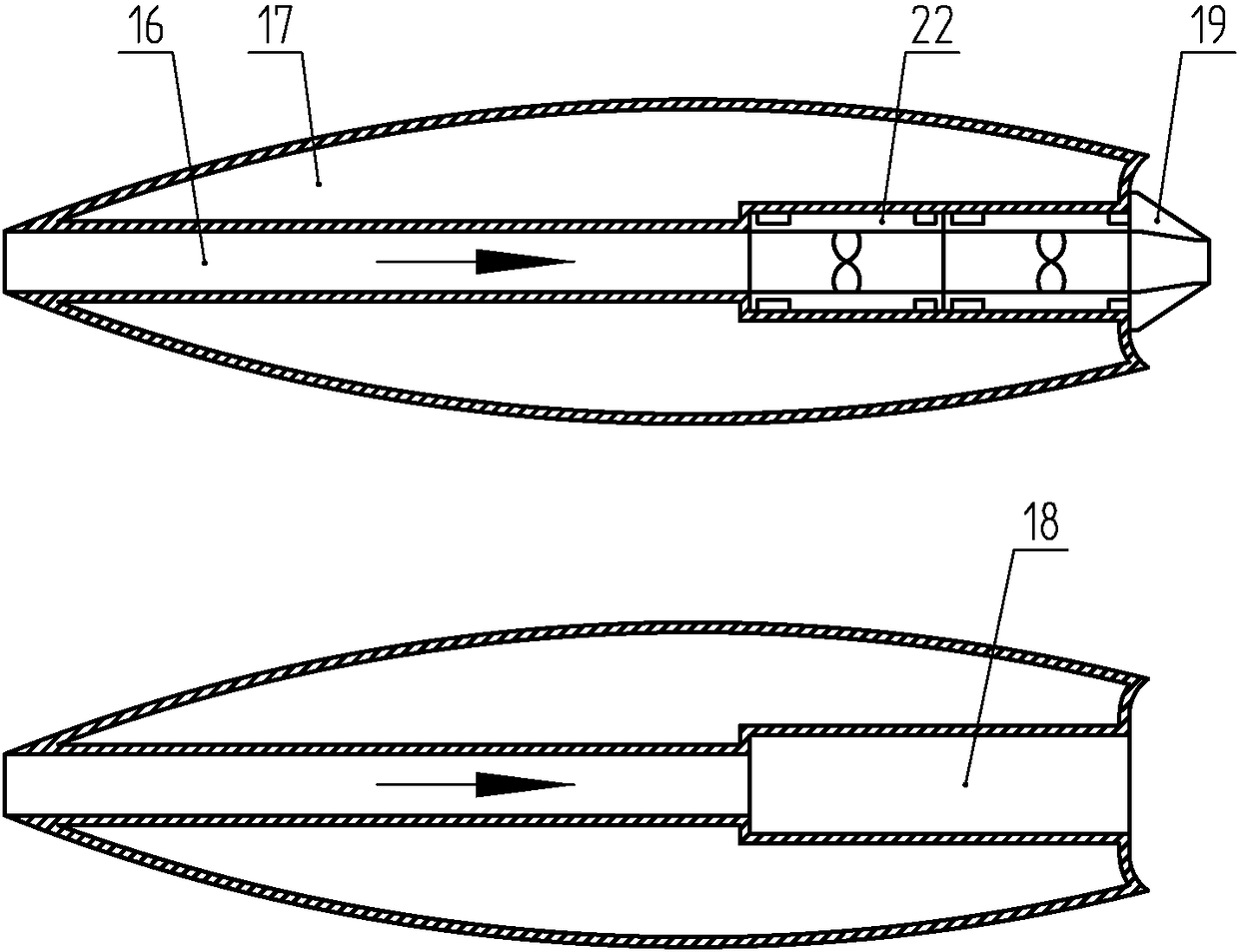

[0036] The guide body 15 is spindle-shaped, and it is symmetrically installed on the left and right sides of the bottom end of the tool body 14. The inside of the guide body 15 is provided with a closed cavity 17 that provides buoyancy, and a flow channel 16 is provided along the axial direction of the guide body 15. 16 rear and the installation hole 18 that communicates with its coaxial, respectively install a propulsion device in each installation hole 18.

[0037] Each propulsion device comprises two propellers 22 installed in series before and after, the propeller 22 positioned at the front is a primary propeller, and the propeller 22 positioned at the rear is a secondary propeller; The inner diameters of the Venturi tube 19 and the Venturi tube 19 decrease sequen...

Embodiment 2

[0050] The difference from Embodiment 1 is that in this embodiment, the number of propulsion devices is one, and the control device only includes a speed sensor, and the speed is adjusted by stepping on the speed sensing area on the surface of the water skateboard, while the steering is performed by swinging the limbs Realize, similar to the steering of the ground skateboard.

Embodiment 3

[0052] The difference from Embodiment 1 is that in this embodiment, the control device can capture body movements instead of pressure sensing, that is, the somatosensory camera recognizes specific body commands and converts them into control signals and transmits them to the control device for manipulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com