A quick-loading protective sleeve structure for drilling tools

A protective cover and quick-installation technology, which is applied in the directions of packaging, transportation, packaging, closing, etc., can solve the problems of laborious installation or removal operation, large axial distance of the protective cover, and few times of repeated use, etc. The effect of small space, simple structure and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

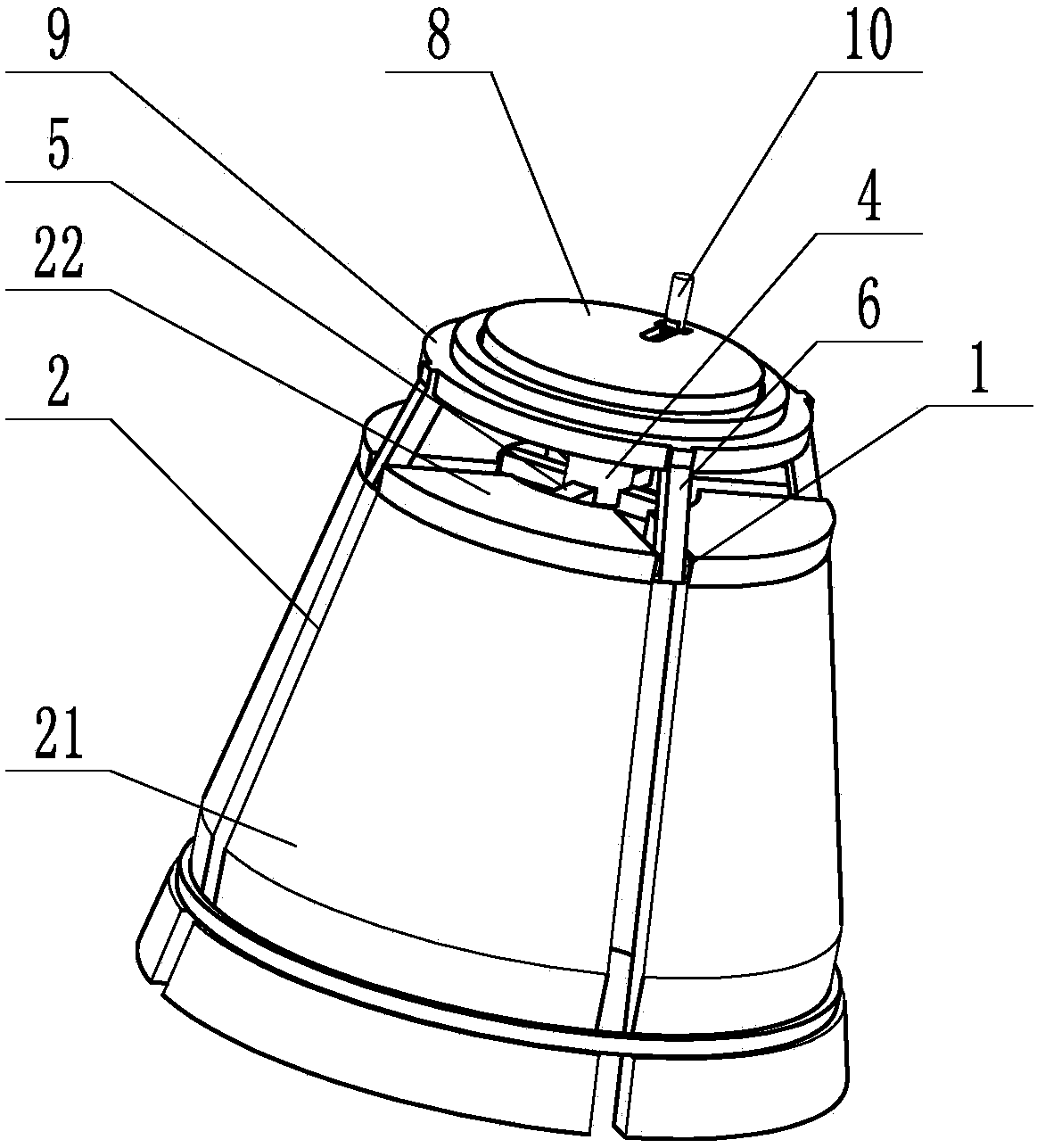

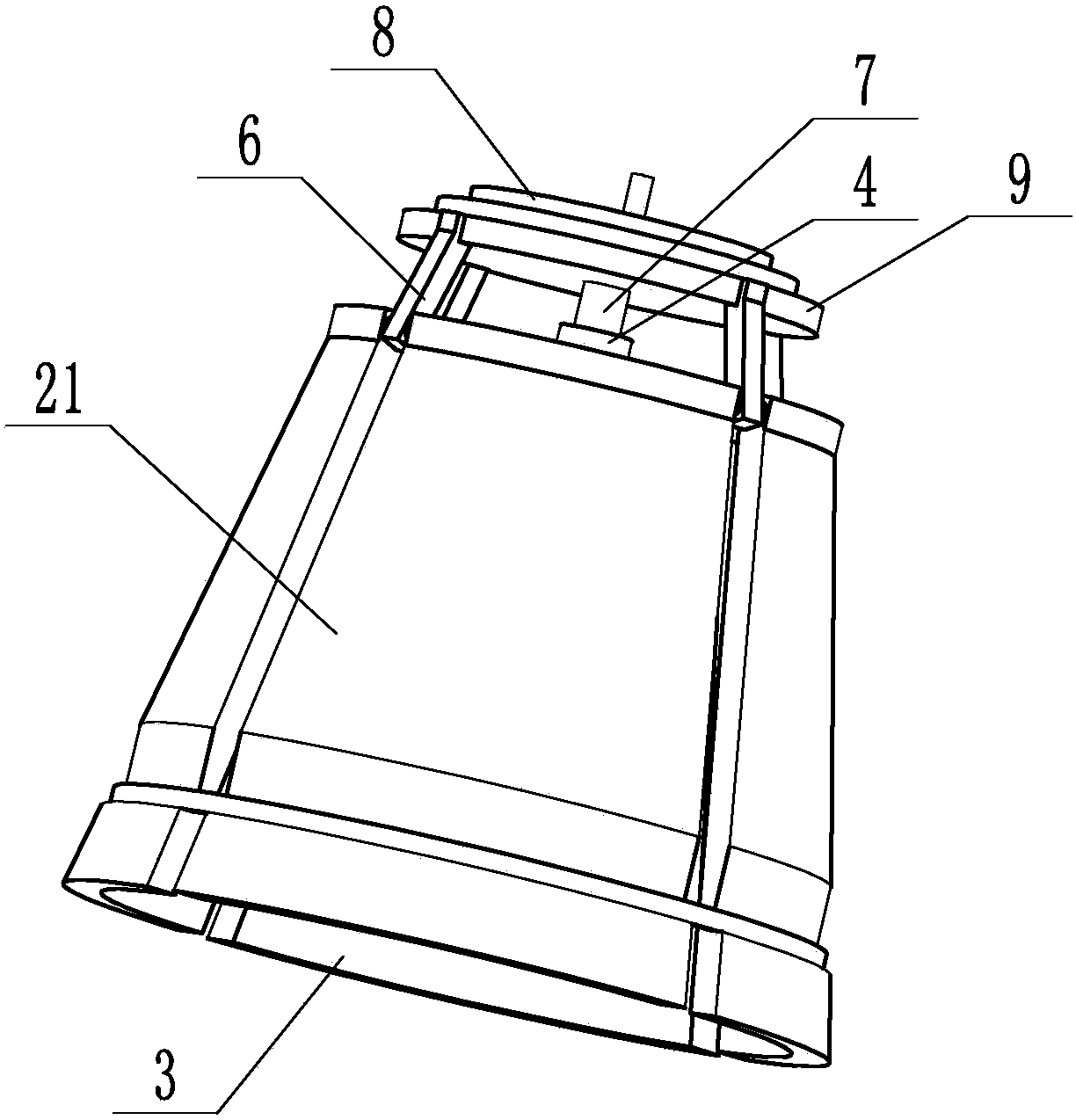

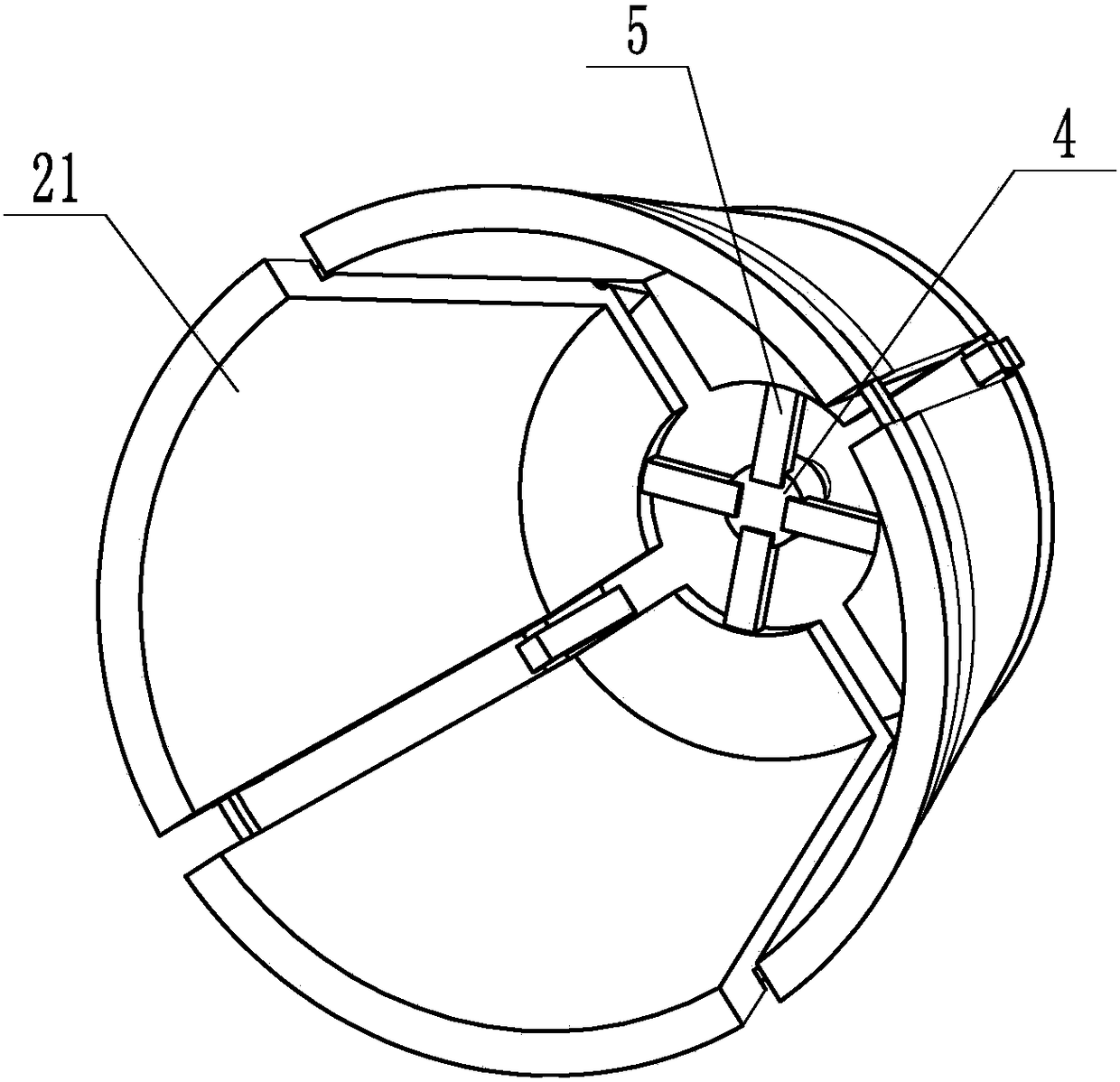

[0015] Such as Figure 1 to Figure 3 As shown, the quick-loading protective sleeve structure of the drilling tool in this embodiment includes a protective ring 1, and a plurality of protective sheets 2 are arranged at intervals along the circumferential direction of the protective ring 1, and the plurality of protective sheets 2 form a cone shape as a whole. The protection chamber 3, the drilling tool is placed in the protection chamber 3; the protection sheet 2 includes a wrapping sheet 21 for wrapping the drilling tool and a swing sheet 22 placed in the protection ring 1, the swing sheet 22 and the wrapping sheet 21 are Formed in one piece, the connecting turning point of the swinging piece 22 and the wrapping piece 21 is rotated and installed on the protection ring 1, and an adjusting sleeve 4 is arranged in the center of the enclosed are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com