An automatic coating line for finished optical fiber

An assembly line and optical fiber technology, applied in the field of optical fiber manufacturing, can solve the problems of insecurity, instability, heavy work tasks, etc., and achieve the effect of reducing labor force, strong practicability, simple and practical combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

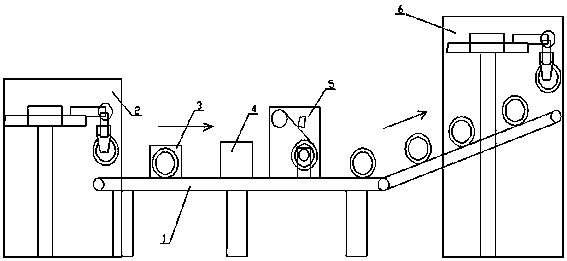

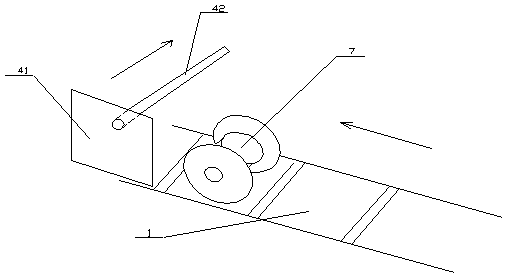

[0021] Such as figure 1 As shown, the present invention discloses an automatic coating line for finished optical fibers, including a conveyor belt 1 arranged horizontally and a feeding system 2, a scanning system 3, a sorting system 4, an automatic winding system 5, Unloading system 6; also includes a production management system electrically connected to the above system;

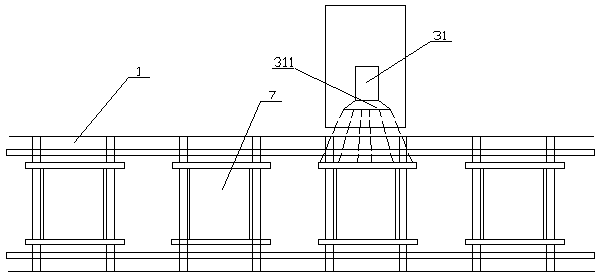

[0022] Such as Figure 6 As shown, the rack 8 carrying the optical fiber tray 7 is placed at the beginning of the conveyor belt, and the mechanical gripper 9 automatically places the optical fiber tray 7 on the conveyor belt 1 in sequence; several optical fibers uniformly distributed along the length direction of the conveyor belt 1 are placed on the conveyor belt 1 Disk 7. In the optical fiber manufacturing industry, the finished optical fiber is wound on the fiber optic disk 7. The fiber disk 7 is a hollow columnar structure with a small middle and large ends. There is a round hole in its axial center. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com