Top drive back-up tong torque arm system

A technology of torque arm and back tong, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., which can solve the problems of lower working efficiency, complexity, and heavy back tong, so as to improve the degree of automation, reduce impact and damage, and save manpower Material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

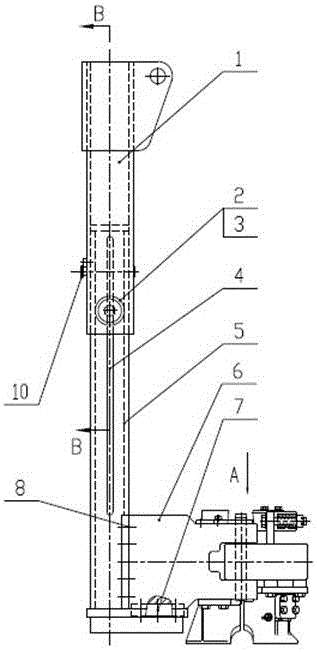

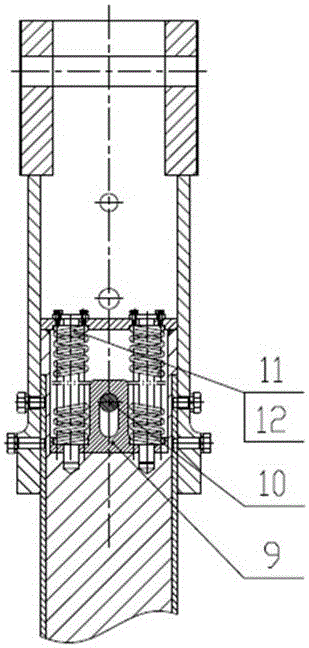

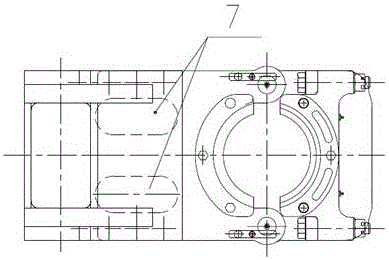

[0018] refer to figure 1 , 2 , 3, a back-up tong torque arm system for top drive, comprising an outer torque arm 1, a lifting motor 2, a lifting gear 3, a rack 4, an inner torque arm 5, a back-up tong device 6, a key 7, a bolt 8, and a connecting frame 9, connecting pin 10, spring 11, guide rod 12. The gap between the outer torque arm 1 and the inner torque arm 5 of the system is set; the inner torque arm 5 is an L-shaped structure, and the lower end of the L-shaped long arm is connected and fixed with the back clamp device 6 by bolts 8, while the L-shaped short arm The upper end surface of the arm is positioned by the key 7 and the bottom of the backup vise device 6 to transmit the make-up and breakout torque. The structure of the external torque arm 1 here is open, that is, there is a gap on the square tube structure at this place. The rack 4 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com