Method for gob-side entry retaining of medium-thickness coal seam

A technology of thick coal seam and empty entry retaining, which is applied in earthwork drilling, filling, safety devices, etc., can solve problems such as high cost, achieve low cost, good supporting effect, and ensure the stability of surrounding rock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

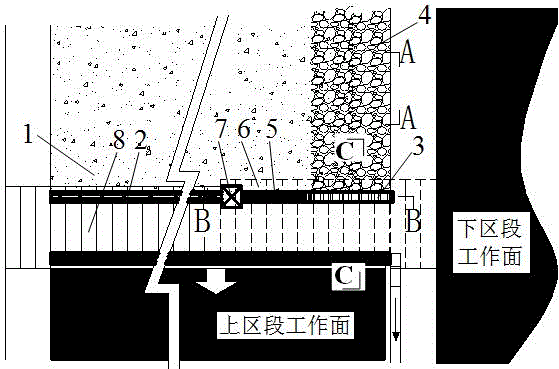

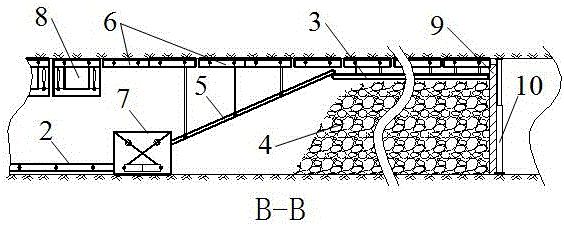

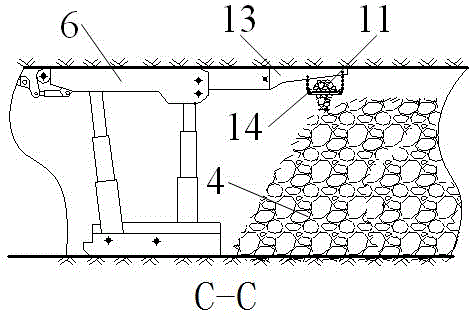

[0019] refer to figure 1 , 2 , 3, 4, and 5 illustrate the present invention, a method for retaining roadway along the goaf in a medium-thick coal seam, utilizes the advantage of large space in the working face of a medium-thick coal seam, at first changes part of the support of the working face on the side of the roadway into the top-coal caving support 8 And the long tail beam support 6, and the scraper conveyor 2, the reloading crusher 7, the transfer belt conveyor 5, and the lifting conveyor 3 are arranged behind the working surface support. During the advancing process of the working face, the gangue 11 above the goaf 1 is lowered directly by the top-coal caving support 8, transported by the scraper conveyor 2, crushed by the reloading crusher 7, and transferred by the transfer belt conveyor 5 to the descending conveyor 3, The lowering conveyor 3 lifts the lowered gangue 11 to the goaf 1 on the side of the roadway to form the roadside support 4, and the whole process is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com