Power control method for fuel gas heating water heater

A gas heating and power control technology, applied in the control of combustion, fluid heaters, lighting and heating equipment, etc., can solve the problems of excess performance of gas heating water heaters, reduced heating power, short use time, etc., to ensure work Effects of performance, large water flow, and high water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

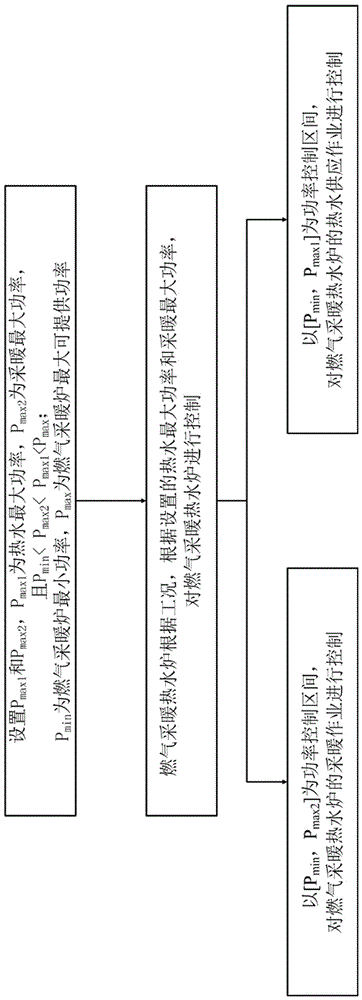

[0019] Such as figure 1 Shown is the method flowchart of the present invention: the power control method of this gas heating water heater provided by the present invention comprises the following steps:

[0020] S1. Set two powers on the control panel or operation display of the gas heating water heater, respectively P max1 and P max2 , with P max1 is the maximum power of hot water, in P max2 is the maximum heating power, and P min max2 max1 max ; where P min is the minimum power of the gas heating furnace, P max It is the maximum power available for the gas heating furnace; 1max1 / P max2 <1.5;

[0021] S2. The gas heating water heater controls the gas heating water heater according to the working conditions and the maximum power of hot water and heating set in step S1:

[0022] with [P min , P max2 ] is the power control interval, which controls the heating operation of the gas heating water heater;

[0023] with [P min , P max1 ] is the power control interval, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com