Manufacturing method for water gun

A manufacturing method and water gun technology, applied to chemical instruments and methods, liquid spray guns, weapons without explosives, etc., can solve problems such as increased weight, increased cost, and unsafety, and achieve accelerated melting speed, increased use times, and lightened effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

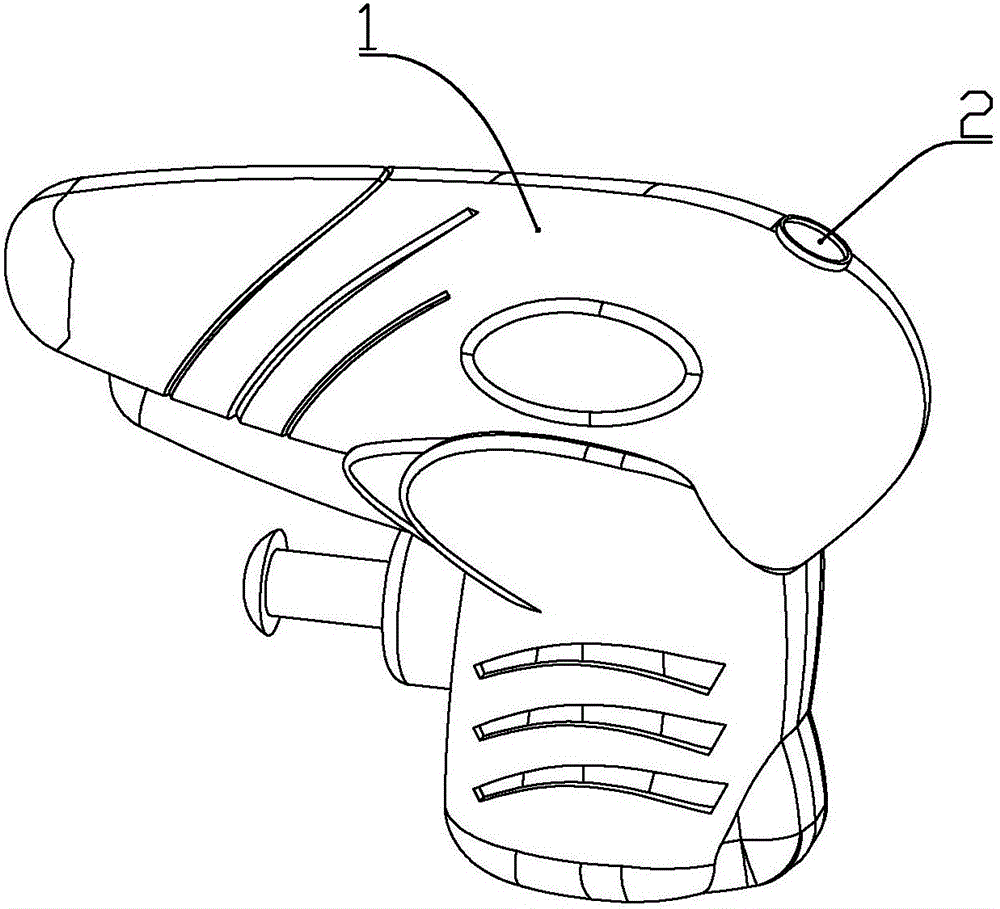

[0045] according to Figure 1 to Figure 5 As shown, this embodiment is a manufacturing method of a toy water gun. The structure of the toy water gun includes a gun body 1 and a plug 2 sealingly inserted into the water filling port of the gun body.

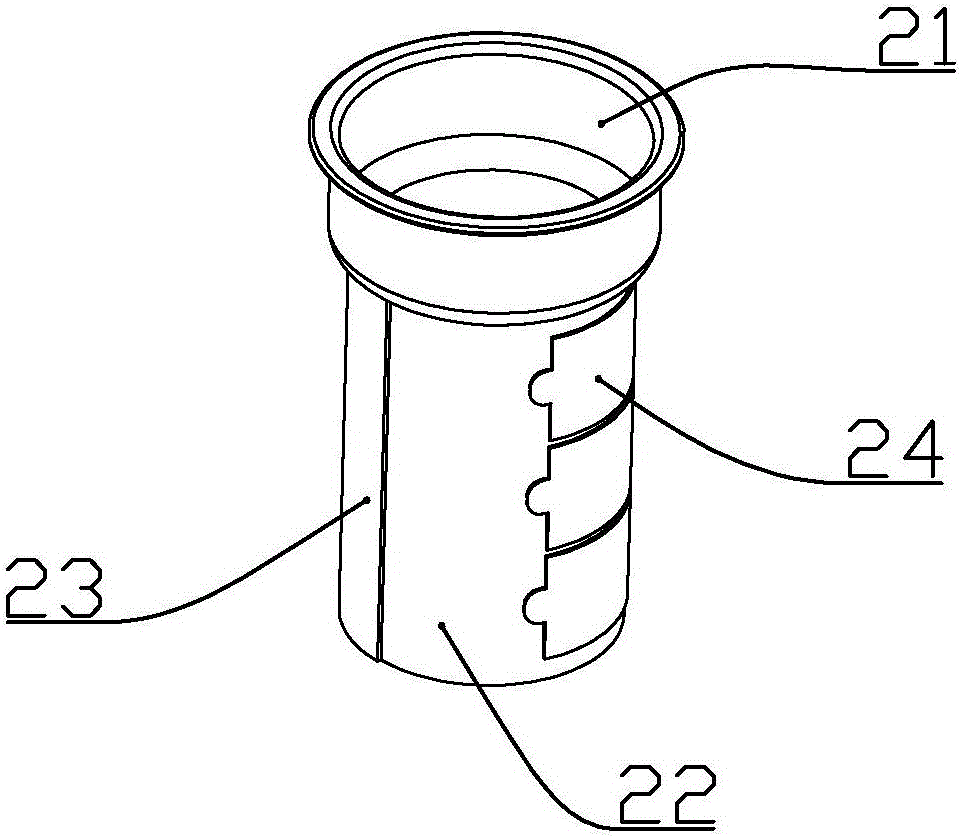

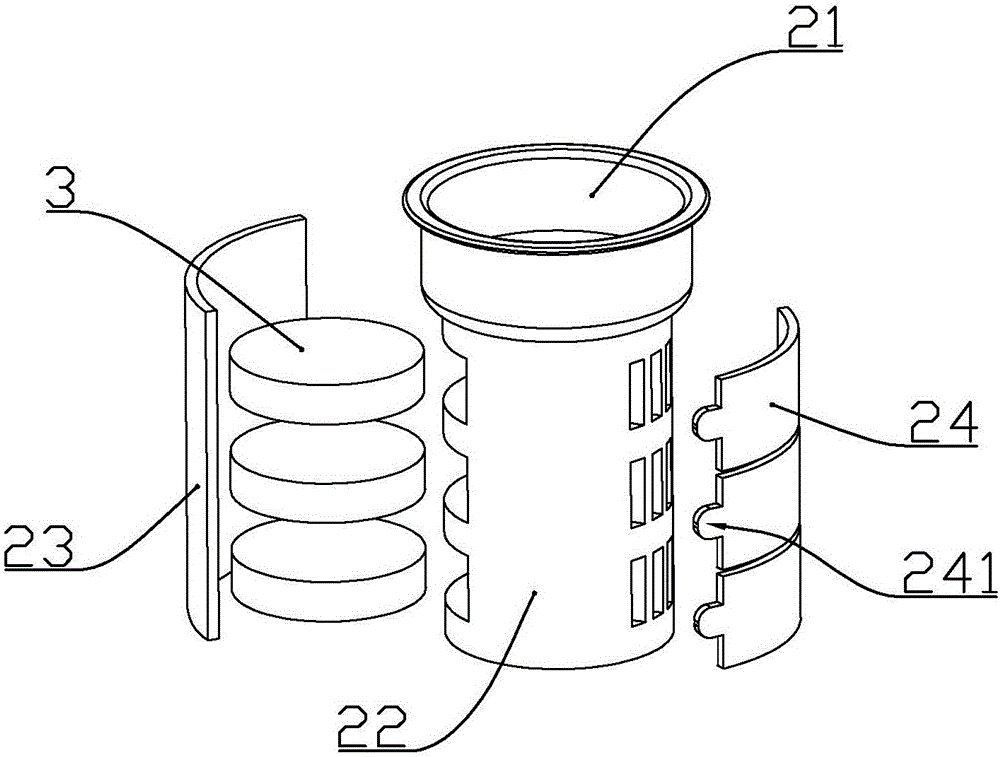

[0046] The plug includes a plug body 21 and a tablet mounting portion 22 integrally formed at the lower end of the plug body, the outer periphery of the upper end of the plug body is formed with an outer flange 211 against the outer wall of the gun; the tablet mounting portion is cylindrical , the tablet installation part is formed with more than two installation bins 220 for installing effervescent tablets along the length direction, and the side wall of the tablet installation part is formed with an inlet 221 for inserting effervescent tablets 3 corresponding to the position of each installation bin. And the grid opening 222 that is arranged opposite to the loading opening to prevent the effervescent tablet from coming out; the g...

Embodiment 2

[0075] according to Figure 1 to Figure 5 As shown, this embodiment is a manufacturing method of a toy water gun. The structure of the toy water gun includes a gun body 1 and a plug 2 sealingly inserted into the water filling port of the gun body.

[0076] The plug includes a plug body 21 and a tablet mounting portion 22 integrally formed at the lower end of the plug body, the outer periphery of the upper end of the plug body is formed with an outer flange 211 against the outer wall of the gun; the tablet mounting portion is cylindrical , the tablet installation part is formed with more than two installation bins 220 for installing effervescent tablets along the length direction, and the side wall of the tablet installation part is formed with an inlet 221 for inserting effervescent tablets 3 corresponding to the position of each installation bin. And the grid opening 222 that is arranged opposite to the loading opening to prevent the effervescent tablet from coming out; the g...

Embodiment 3

[0105] according to Figure 1 to Figure 5 As shown, this embodiment is a manufacturing method of a toy water gun. The structure of the toy water gun includes a gun body 1 and a plug 2 sealingly inserted into the water filling port of the gun body.

[0106] The plug includes a plug body 21 and a tablet mounting portion 22 integrally formed at the lower end of the plug body, the outer periphery of the upper end of the plug body is formed with an outer flange 211 against the outer wall of the gun; the tablet mounting portion is cylindrical , the tablet installation part is formed with more than two installation bins 220 for installing effervescent tablets along the length direction, and the side wall of the tablet installation part is formed with an inlet 221 for inserting effervescent tablets 3 corresponding to the position of each installation bin. And the grid opening 222 that is arranged opposite to the loading opening to prevent the effervescent tablet from coming out; the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com