Optical axis and mounting reference surface parallelism test device and method

A technology for installing benchmarks and testing devices, used in measuring devices, optical devices, instruments, etc., can solve the problems of difficult optical axis online adjustment, low degree of automation, low detection accuracy, etc., and achieve the effect of high longitude and convenient detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

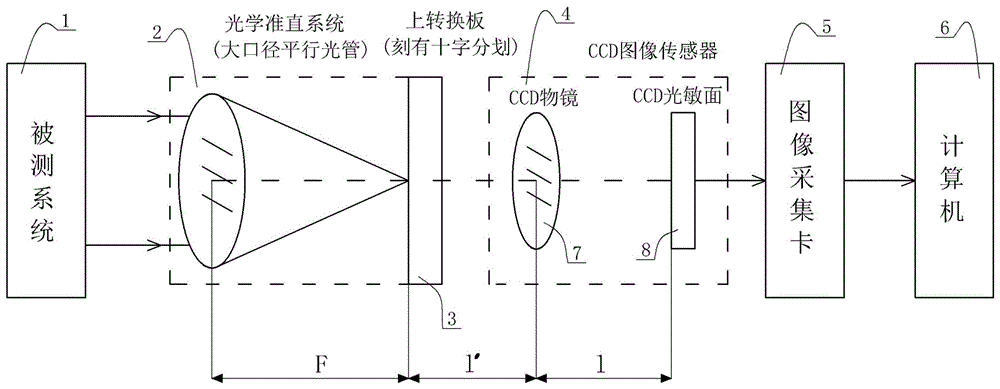

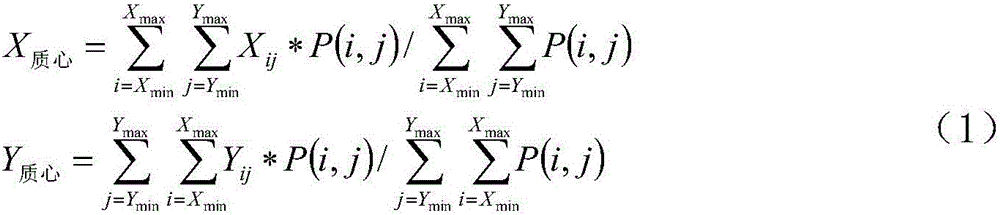

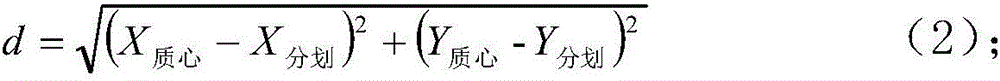

[0027] Such as figure 1 As shown, a schematic structural view of the optical axis and the installation reference plane parallelism testing device of the present invention is provided, which is composed of an optical collimation system 2, an up conversion board 3, a CCD image sensor 4, an image acquisition card 5 and a computer 6, The optical axis of the optical collimation system 2 coincides with the optical axis of the CCD image sensor 4, and is parallel to the installation reference plane of the laser illuminator. The upper conversion plate 3 is located on the focal plane of the optical collimation system 2. The laser spot emitted by the system under test 1 is focused on the up-conversion board 3 , and the CCD image sensor 4 is composed of a CCD objective lens 7 and a CCD photosensitive surface 8 . The up-conversion board 3 converts the laser spot fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com