A hyperspectral batch non-destructive testing method and system for the quality of agricultural and livestock products

A technology for non-destructive testing of agricultural and livestock products, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low detection speed of agricultural and livestock products, consistency of spectrum acquisition sensor signals, etc., to ensure consistency, The effect of improving detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

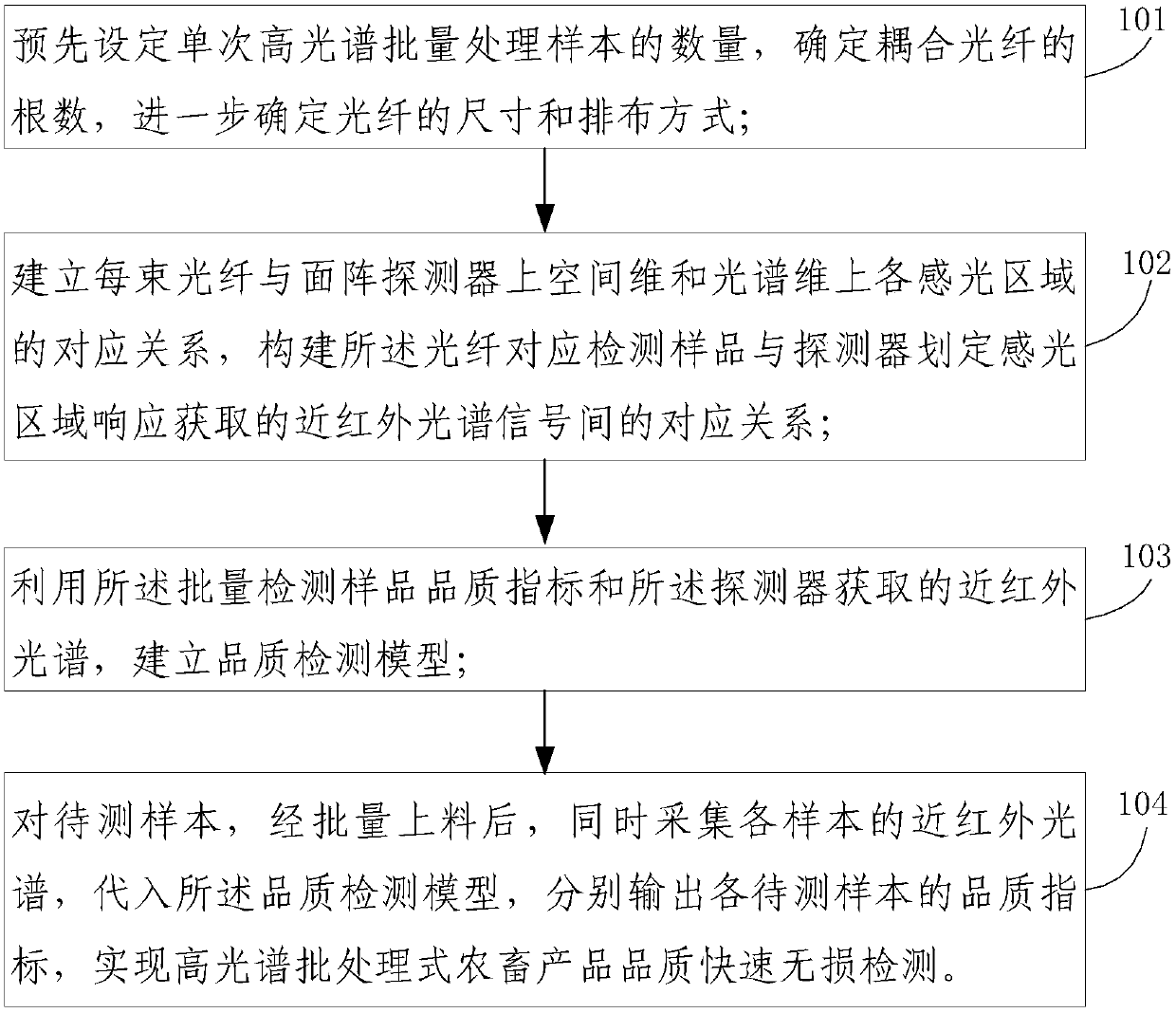

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention proposes a hyperspectral batch-processing non-destructive detection method for the quality of agricultural and livestock products, the method comprising the following steps:

[0036] Step 101: presetting the number of samples for a single hyperspectral batch processing, determining the number of coupling fibers, and further determining the size and arrangement of the fibers;

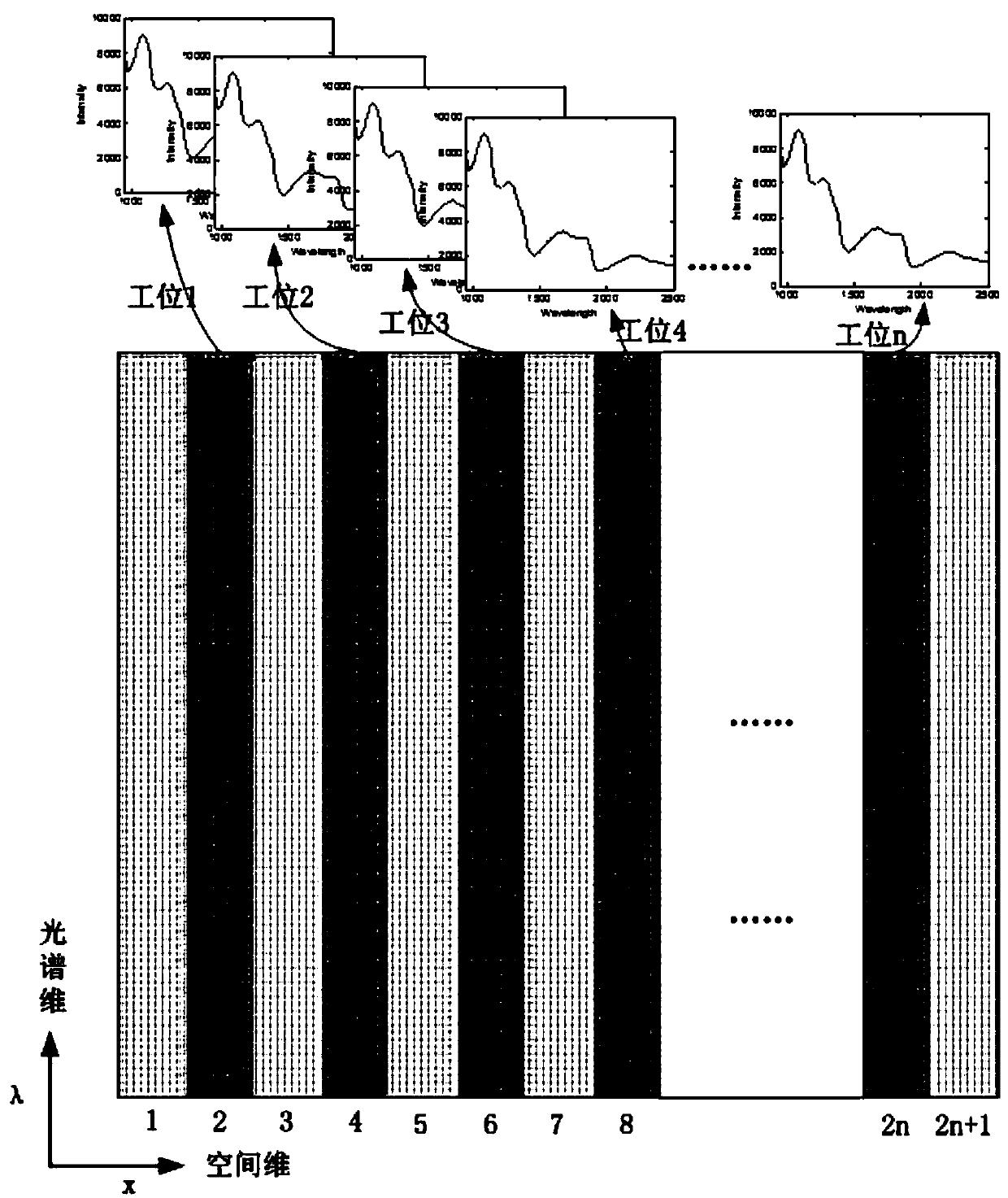

[0037] Step 102: Establish the corresponding relationship between each bundle of optical fibers and the photosensitive regions on the spatial and spectral dimensions of the area array detector, and construct the corresponding relationship between the optical fiber corresponding to the detection sample and the near-infrared spectral signal obtained in response to the delimited photosensitive region of the detector ;

[0038] Step 103: using the quality indicators of the batch testing samples and the near-infrared spectrum obtained by...

Embodiment 2

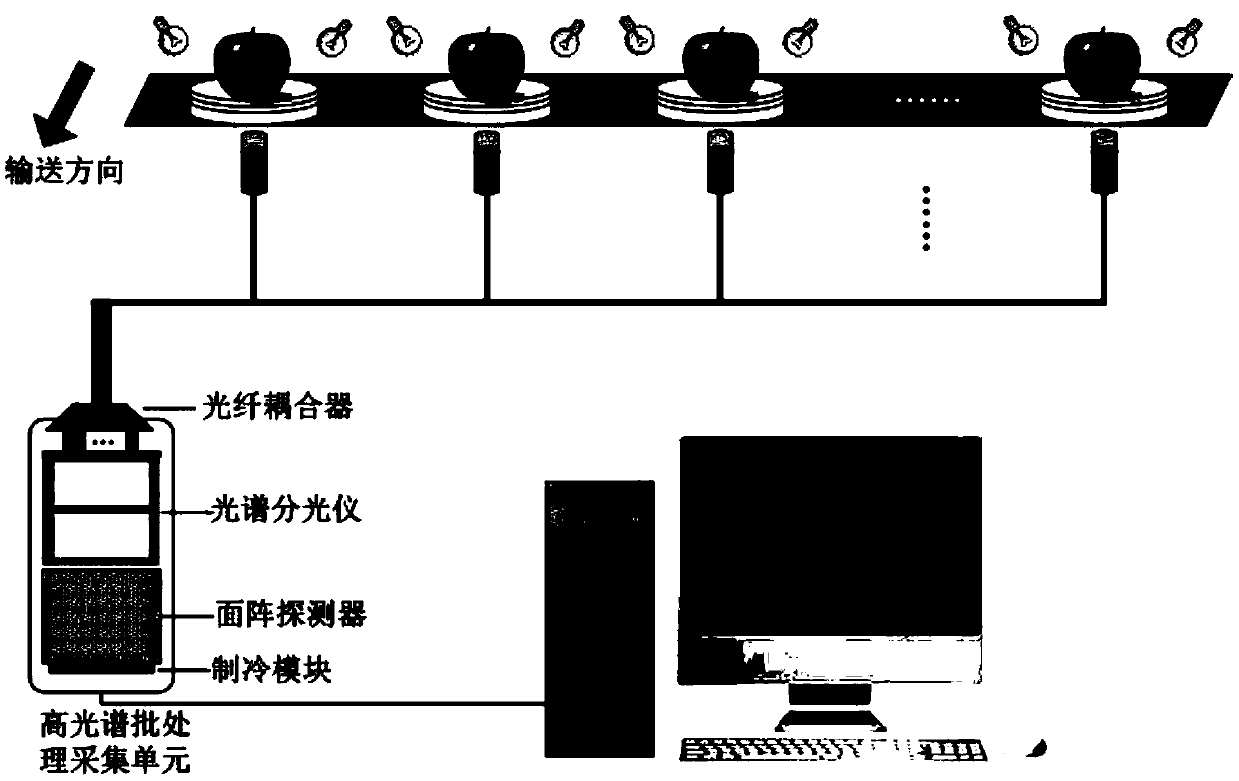

[0048] The present invention also proposes a hyperspectral batch-processing non-destructive detection system for the quality of agricultural and livestock products, such as figure 2 As shown, the system includes: a material delivery unit, a light source kit group, a hyperspectral batch processing acquisition unit, a photoelectric switch and control unit, and a computer, wherein:

[0049] The material conveying unit includes one of a conveying belt or a chain plate, and at least one tray for conveying agricultural and livestock products in batches, and the at least one tray is equidistantly arranged on the belt conveying group for batching samples to be tested transported to the set station to be inspected;

[0050] The light source kit group includes at least an even number of light source kits, a pair of light sources are symmetrically arranged on both sides of each station to be inspected, and the centers of all light sources are on the same straight line, which is used to ...

Embodiment 3

[0060] In this embodiment, apples are taken as an example, and the hyperspectral batch-processing nondestructive testing method and system for agricultural and livestock products are used to obtain near-infrared spectrum data groups representing apple quality information in batches, establish an apple quality detection model, and realize rapid nondestructive testing of apples in batches. :

[0061] The number of apples to be processed in a single batch is preset to be 10, and the number of coupling fibers to be 10, that is, an apple sample for each detection station corresponds to an optical fiber; The joints of the instrument are arranged with single lines at equal intervals, and the transmitted light of the apple sample to be tested is transmitted to the second end of the optical fiber through the first end of the optical fiber, and enters the spectral spectrometer at the second end through the slit of the spectroscopic spectrometer, Through the prism-grating-prism combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com