Method for detecting ultrasonic three-dimensional imaging of lamellarflaw distribution

A technology of three-dimensional imaging and defect distribution, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific examples of implementation.

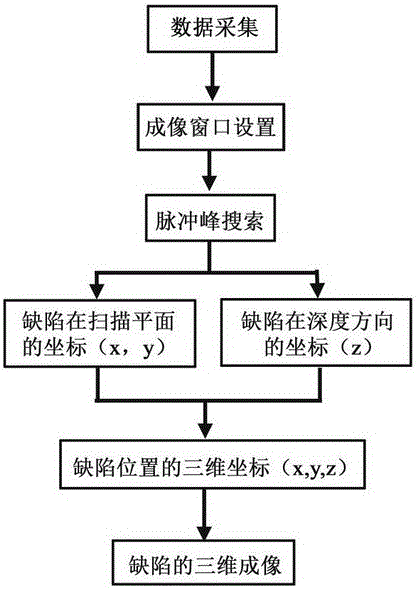

[0030] (1) 3D imaging data acquisition method

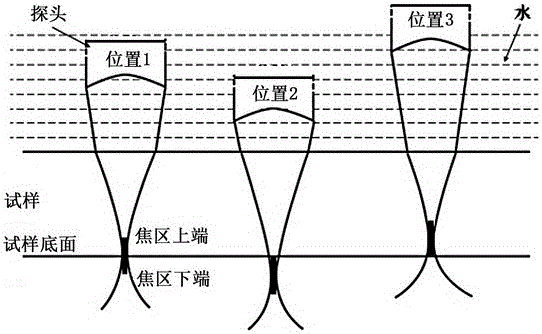

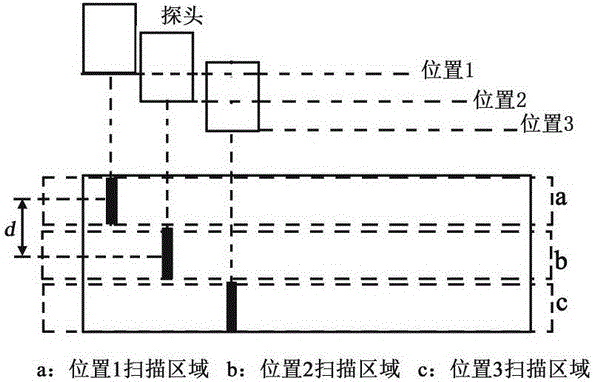

[0031] The ultrasonic water immersion focusing method can make the probe move freely above the detection object and maintain a uniform and good acoustic coupling performance. It is the main data acquisition method for automatic scanning imaging. Affected by the interference of the acoustic beam and the spherical aberration of the acoustic lens, the energy of the focused acoustic beam is not focused on one point, but a focused area with higher energy is formed near the focal point. In this focused area, better detection accuracy and sensitivity can be maintained. The invention collects layered C-scan data on the test block based on the water immersion focusing method. figure 1 Display: Set the layer scan interval to d , when the probe is at positions 1, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com