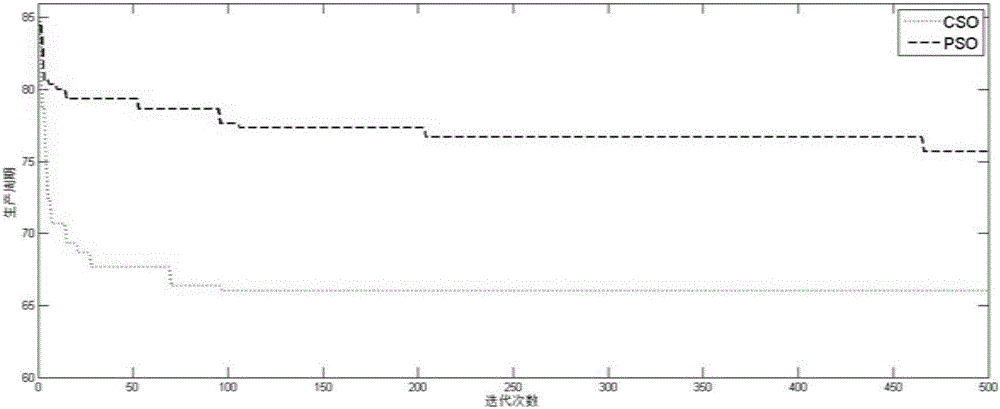

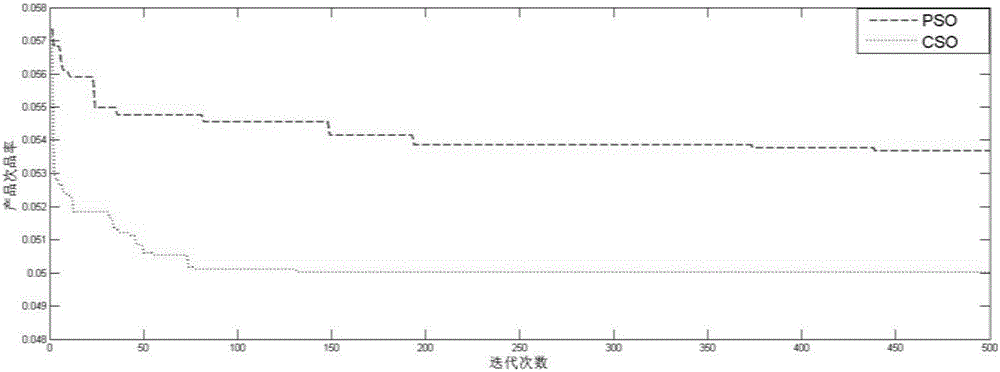

Discrete manufacture workshop scheduling method based on improved cat group algorithm

A technology of discrete manufacturing workshop and cat group algorithm, which is applied in the direction of control/regulation system, calculation, calculation model, etc., and can solve problems such as convergence accuracy and speed that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

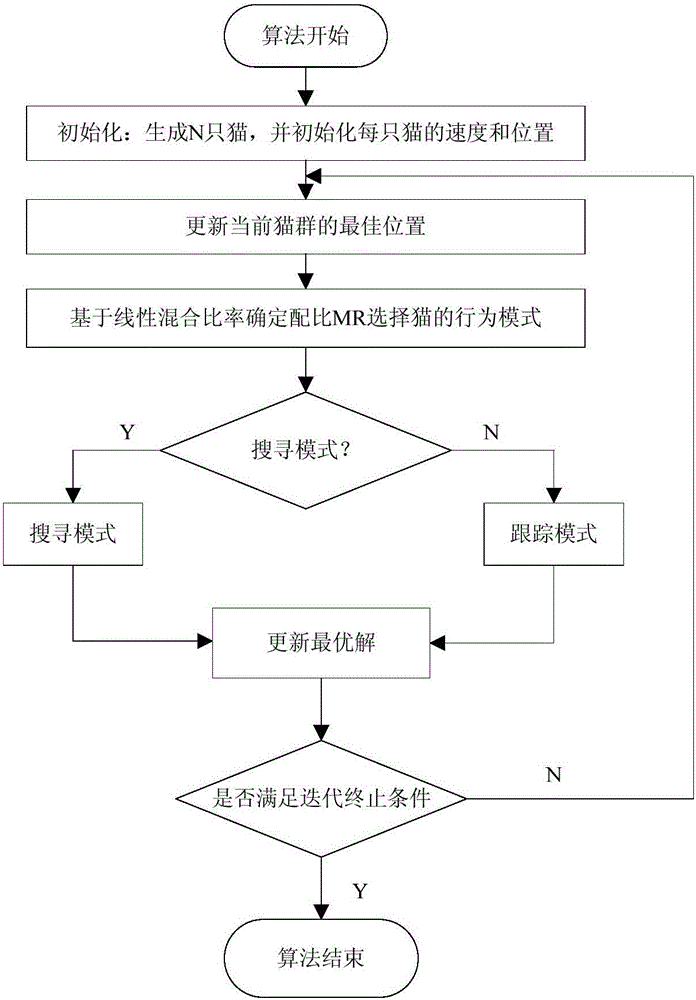

[0064] The implementation of the present invention generally includes three stages:

[0065] The first stage: Establish a multi-objective scheduling model for the workshop. The first stage includes two steps:

[0066] Step 1: According to the scheduling goal, determine the objective function of the workshop scheduling: production cycle, product defective rate, maximum completion time, production energy consumption, and describe them with mathematical functions.

[0067] Step 2: According to the production status of the workshop, product processing requirements, and order requirements, determine the scheduling constraints, including three conditions: process constraints, machine constraints, and time constraints.

[0068] The second stage: cat group algorithm. Cats are generally in two modes: searching mode and tracking mode. Designate a ratio MR so that a small number of cats are in tracking mode and most of the remaining cats are in hunting mode, and combine these two modes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com