Intelligent design method of clamp structure

A technology of intelligent design and fixtures, applied in computing, special data processing applications, instruments, etc., can solve problems such as low design efficiency and difficulty in reusing knowledge in the field of fixture design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

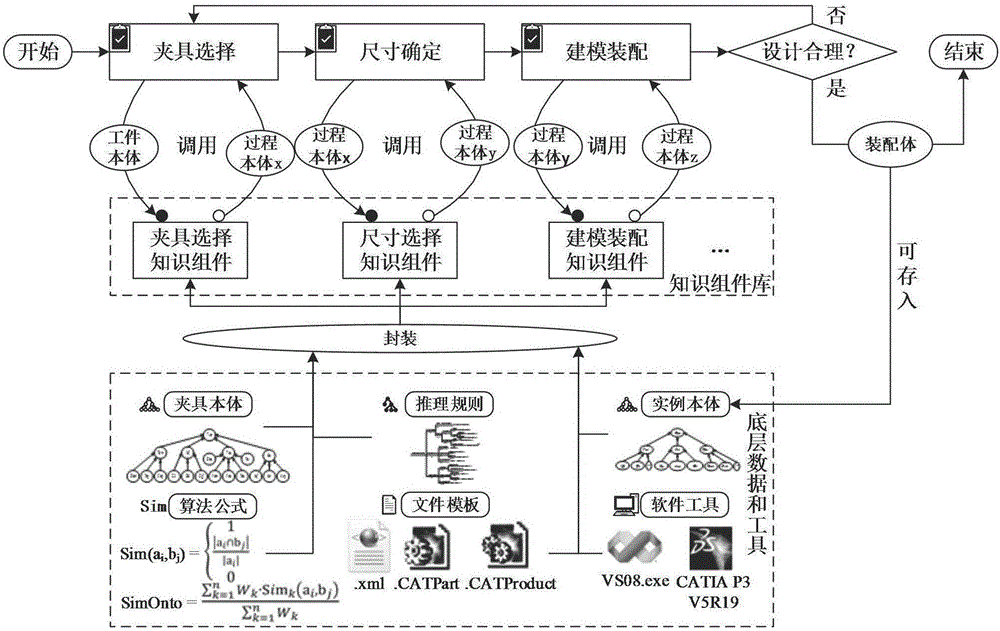

Method used

Image

Examples

Embodiment 1

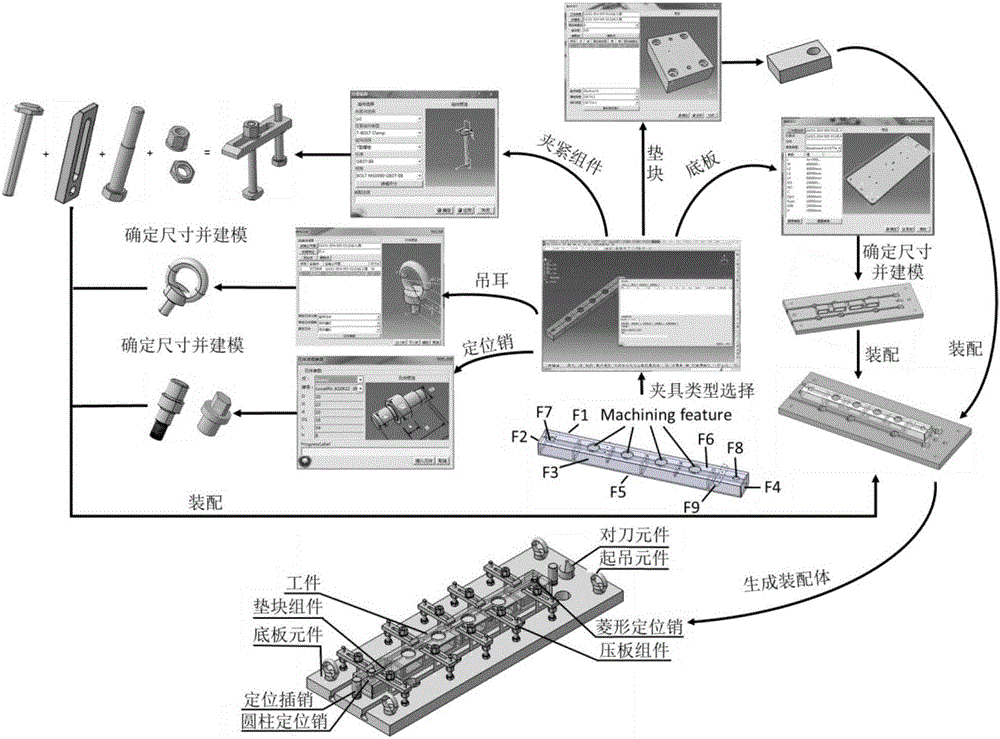

[0054] An intelligent design method for a fixture structure, the specific steps are as follows:

[0055] Step 1. Construct the ontology model of a certain beam part on the aircraft by using ontology-based representation method, and establish the fixture component ontology library and instance ontology library;

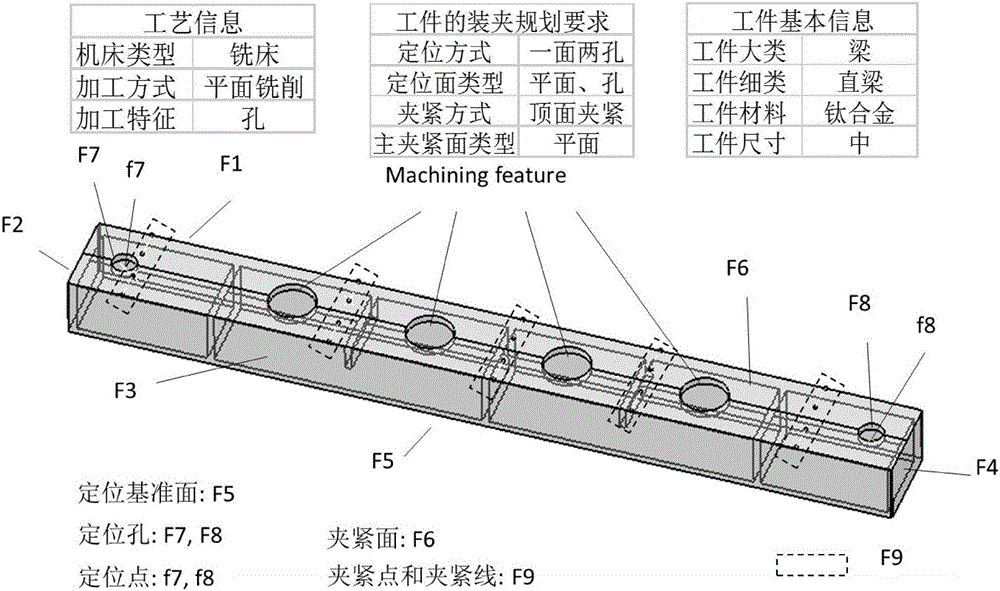

[0056] (1) Construct the body model of a beam part on the aircraft. like figure 1 As shown in the figure, a beam part on the aircraft needs to mill holes on the surface F6, and its body model includes the three-dimensional solid model of the workpiece, the basic information of the workpiece and the clamping planning requirements of the workpiece. Among them, the basic information of the workpiece includes: the major category of the workpiece is beam; the fine category of workpiece is straight beam; the material of the workpiece is titanium alloy; the size of the workpiece is medium size. The clamping planning requirements of the workpiece are: the positioning method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com