Transformer coil

A technology of transformers and coils, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor components, inductor/transformer/magnet manufacturing, etc. Achieve the effect of increasing winding times, stable winding state, improving skin effect and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

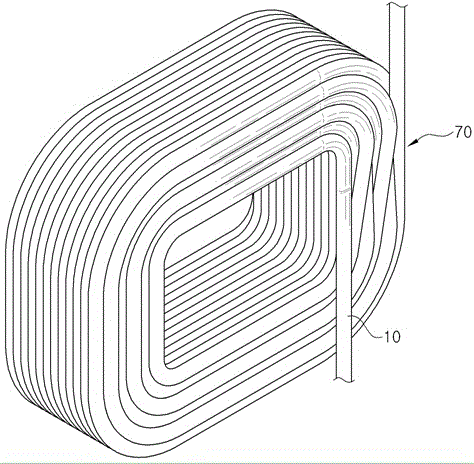

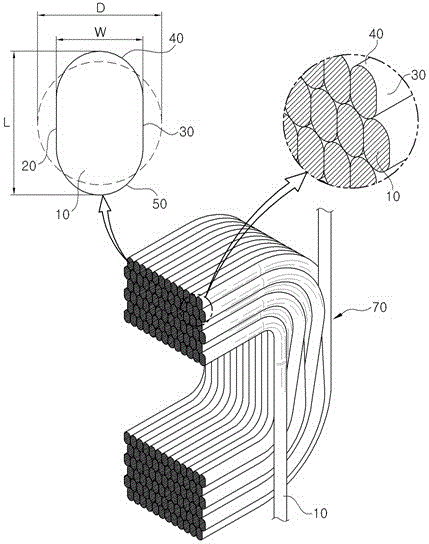

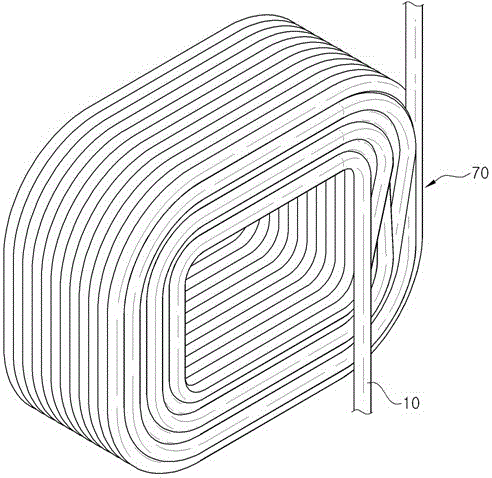

[0027] figure 1 It is a perspective view of a transformer coil applicable to an embodiment of the present invention (D:W=1:0.89, D:L=1:1.03), figure 2 Yes figure 1 cross-sectional oblique view of image 3 It is a perspective view of a coil for a transformer applicable to another embodiment of the present invention (D:W=1:0.79, D:L=1:1.04), Figure 4 Yes image 3 cross-sectional oblique view.

[0028] like figure 1 arrive figure 2 As shown, the coil for a transformer in a preferred embodiment of the present invention, wherein the coil for a transformer formed by winding a coil wire is characterized in that: the above-mentioned coil wire 10 with a specific diameter D and a circular cross-section is tightly wound from left to right, wherein the above-mentioned coil The left side 20 and the right side 30 of the wire 10 are flat up and down, the upper side 40 of the above-mentioned coil wire 10 is circularly convex upward, and the lower side 50 of the above-mentioned coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com