Packaging structure for photoelectron integrated chip

A packaging structure and integrated chip technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve problems affecting the transmission and reflection characteristics of devices, and achieve the effects of reducing the impact, avoiding the use of gold wires, and good impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

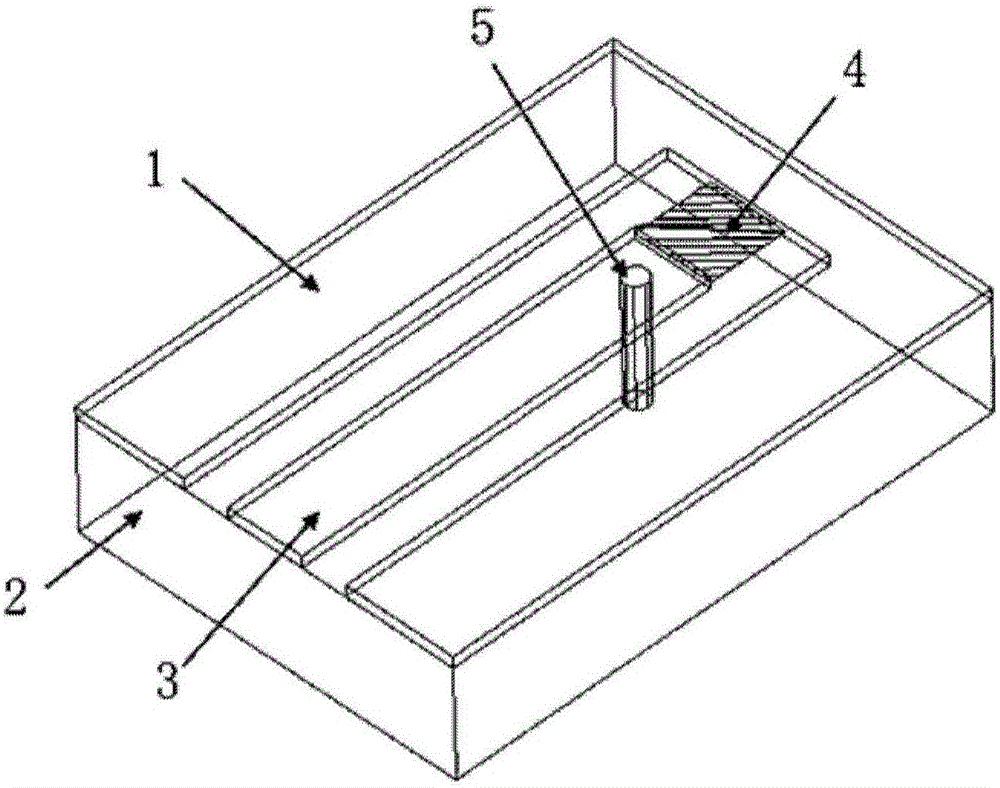

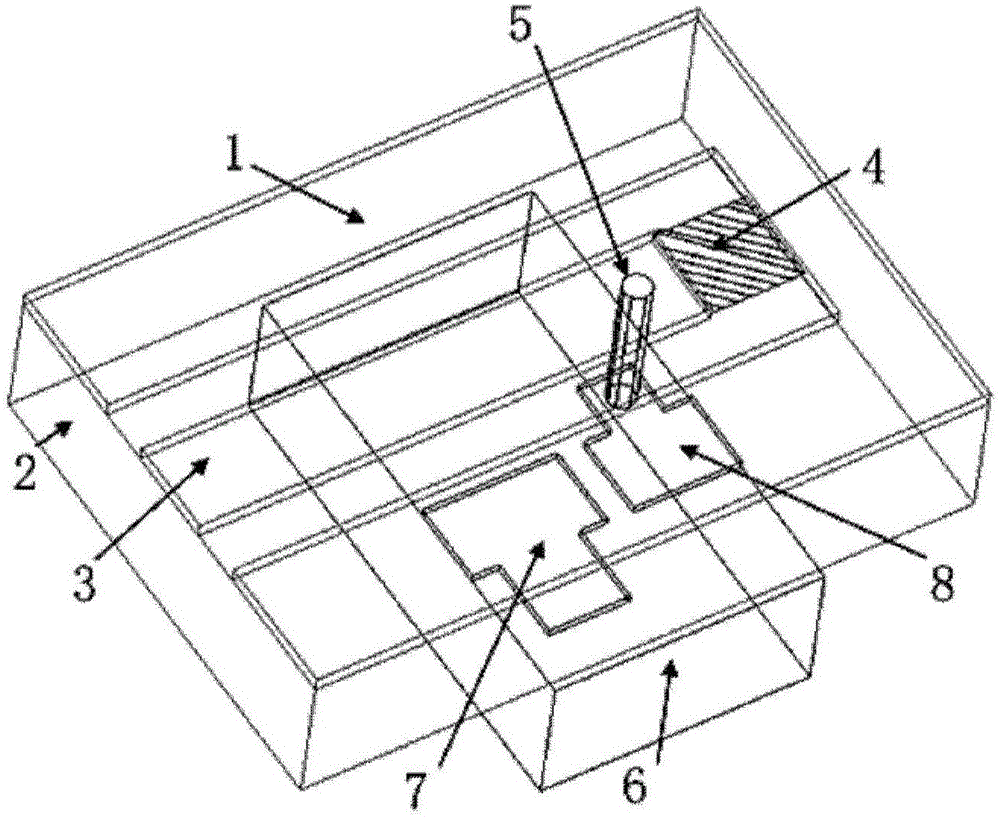

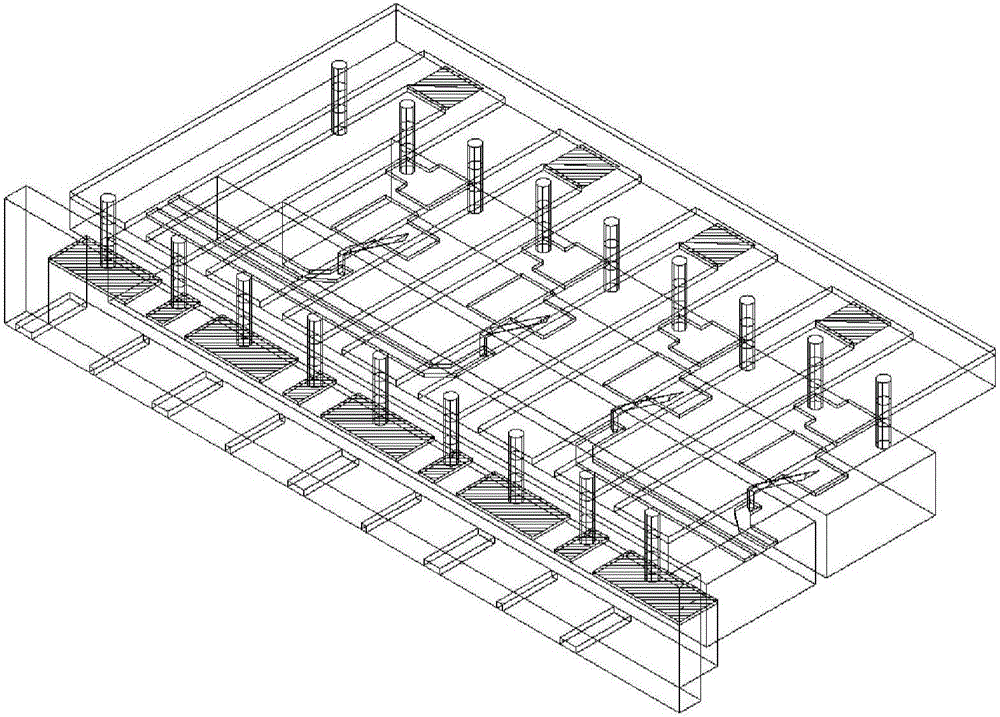

[0027] The invention discloses a packaging structure for an optoelectronic integrated chip, comprising:

[0028] A dielectric substrate, which mainly plays the role of supporting the surface electrodes and confining the electromagnetic field; the surface of the dielectric substrate is evaporated with a certain thickness of coplanar waveguide electrodes by thin film technology, that is, the ground electrode G, the signal electrode S, and the thin film resistance;

[0029] A metal via post, mainly used for signal transmission, connecting signal electrodes and chip electrodes, and supporting dielectric substrate; it can be made by via hole and filling process;

[0030] A matching resistor, connected in parallel with the chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com