Photosensitive device and its preparation method, photosensitive detector

A technology for photosensitive detectors and photosensitive devices, which is applied in the manufacture of semiconductor devices, electrical components, and final products. The effect of improving detection accuracy and improving photosensitive accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

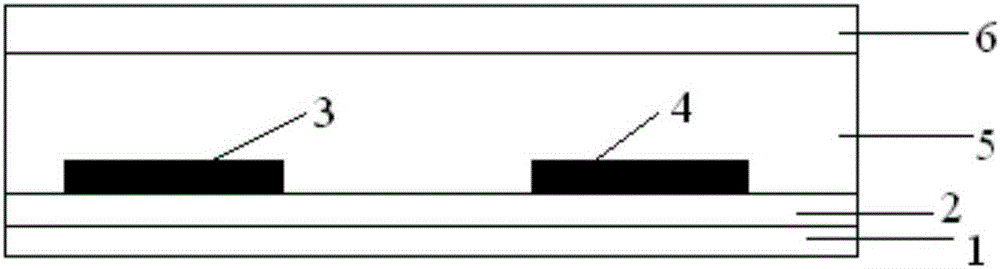

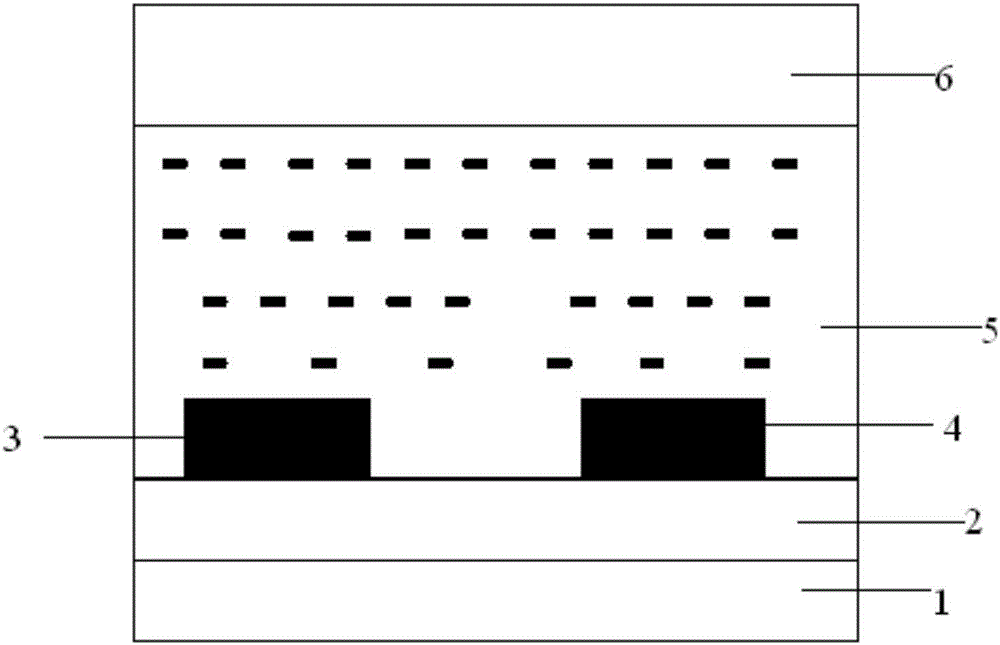

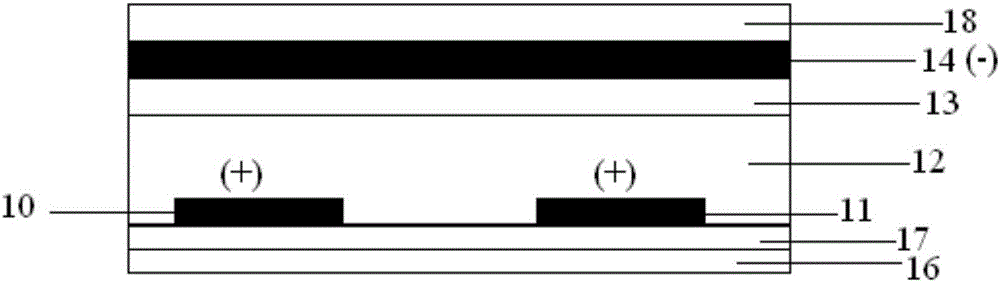

[0028] image 3 A schematic structural diagram of a photosensitive device provided by an embodiment of the present invention; Figure 4 for image 3 Schematic diagram of the electric field within the active photosensitive layer of the photosensitive device shown; see also image 3 with Figure 4 , The photosensitive device provided by the embodiment of the present invention includes: a first electrode 10 , a second electrode 11 , an active photosensitive layer 12 , a first insulating layer 13 and a transparent electrode layer 14 . Wherein, the first insulating layer 13 is formed on the first surface of the active photosensitive layer 12, the active photosensitive layer 12 may be but not limited to GaAs, the first insulating layer 13 may be but not limited to SiN x The transparent electrode layer 14 is formed on the surface of the first insulating layer 13 opposite to the active photosensitive layer 12, the transparent electrode layer 14 can be but not limited to ITO materia...

Embodiment 2

[0042] An embodiment of the present invention provides a photosensitive detector, including a photosensitive device, and the photosensitive device adopts the photosensitive device provided in Embodiment 1 of the present invention.

[0043] The photosensitive detector provided by the present invention can improve detection accuracy because it adopts the above-mentioned photosensitive device provided by the present invention.

Embodiment 3

[0045] Figure 7 For the flow chart of the preparation method of the photosensitive device provided by the embodiment of the present invention, please refer to Figure 7 , the embodiment of the present invention also provides a method for preparing a photosensitive device, comprising the following steps:

[0046] S1, providing an active photosensitive layer, one side of which is formed with a first electrode and a second electrode.

[0047] S2, a first insulating layer is formed on the first surface of the active photosensitive layer, and the first insulating layer is disposed opposite to the first electrode and the second electrode;

[0048] S3, forming a transparent electrode layer on the first insulating layer, where the transparent electrode layer is disposed opposite to the active photosensitive layer;

[0049] S4. Connect both the first electrode and the second electrode to a first power supply, connect the transparent electrode layer to a second power supply, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com