Manufacturing technology of LED bracket with good air-tightness

A LED bracket and manufacturing process technology, applied in the field of LED brackets, can solve problems such as easy contamination of the coating and poor airtightness of the LED bracket, and achieve the effects of improving airtightness, ensuring airtightness, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

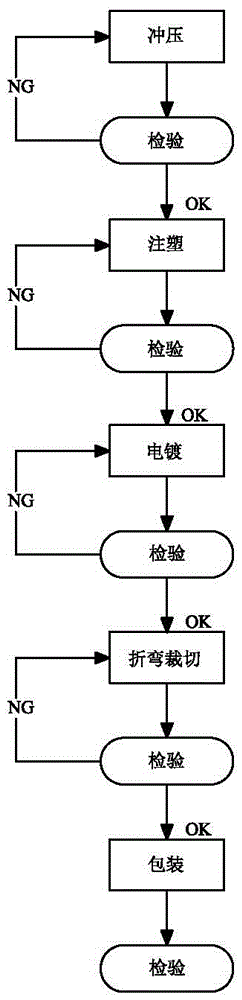

[0023] The invention discloses a manufacturing process of an LED bracket with good airtightness, such as figure 1 shown, including the following steps:

[0024] (1) Stamping: use a press and a mold to stamp and form a metal bracket.

[0025] (2) Inspection: The metal bracket is inspected to sort out qualified products and defective products. If the metal bracket is NG, it will return to stamping. If the metal bracket is OK, it will enter the next process. The inspection adopts the combination of first article inspection and patrol inspection. way.

[0026] (3) Injection molding: put the qualified metal bracket into the injection mold for injection molding to form an insulator, so that the metal bracket and the insulator are fixed together by mosaic molding.

[0027] (4) Inspection: inspect the semi-finished products after injection molding to sort out qualified products and defective products; if the semi-finished products are NG, return to continue injection molding, if the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com