Strain clamp drainage plate with temperature control heating automatic shunting and alarm apparatus

A technology of tension clamp and alarm device, which is applied to the parts, coupling devices, electrical components of connecting devices, etc., can solve the problems of being vulnerable to wind, unsightly, and swinging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

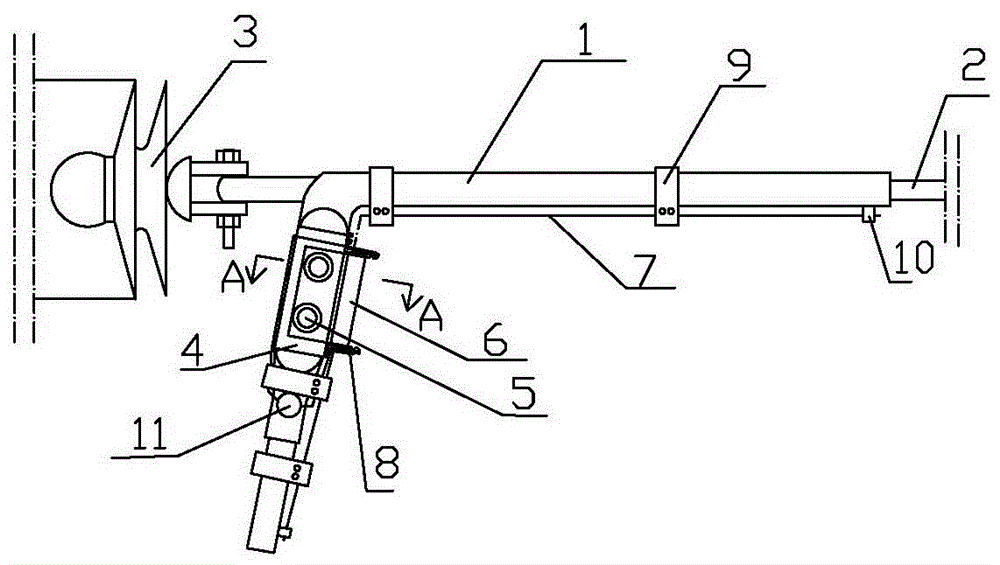

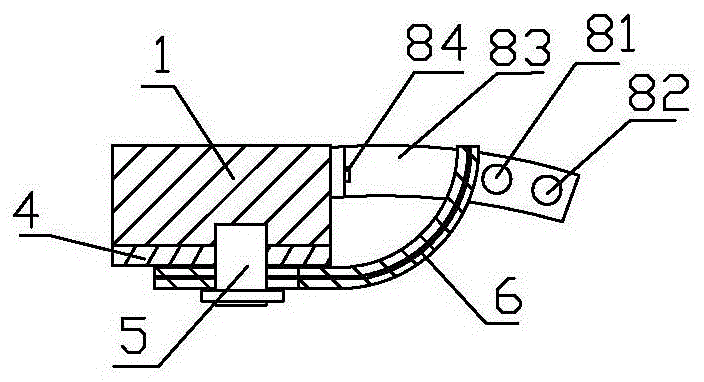

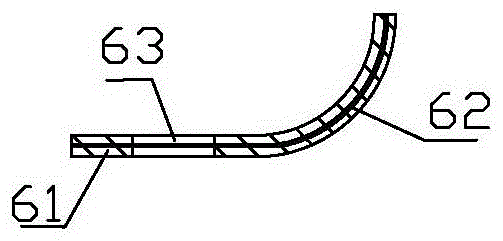

[0015] figure 1 , figure 2 , image 3 , Figure 4 An example of the invention is given. refer to figure 1 , figure 2 , image 3 , Figure 4 Make the invention. The strain clamp drainage plate with temperature control heating automatic shunt and alarm device includes a tension clamp drainage plate 1, one end of the tension clamp drainage plate 1 is connected to the drainage wire 2, and the tension clamp drainage plate 1 The bent end is connected with the insulator 3, and a bolt fixing plate 4 is provided on the handle wall of the tension clamp drainage plate 1, and the feature is that the bolt 5 is passed on the bolt fixing plate 4 of the tension clamp drainage plate 1 Fix the bimetal temperature measuring piece 6, through the bimetal temperature measuring piece 6 to detect the temperature change of the strain clamp drainage plate 1, especially the temperature change of the position of the bolt fixing plate 4; on the inner side wall of the tension clamp drainage plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com