Dishwasher condensation drying system, condensation drying method and dishwasher

A technology of condensation drying and dishwasher, which is applied to the parts of dishwashing machine/rinsing and washing machine, etc., can solve the problems of affecting the life of metal and electronic components, damage to the electric control system of the fan, and reduction of drying efficiency, so as to improve drying condensation. Efficiency, extended fan life, accelerated drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

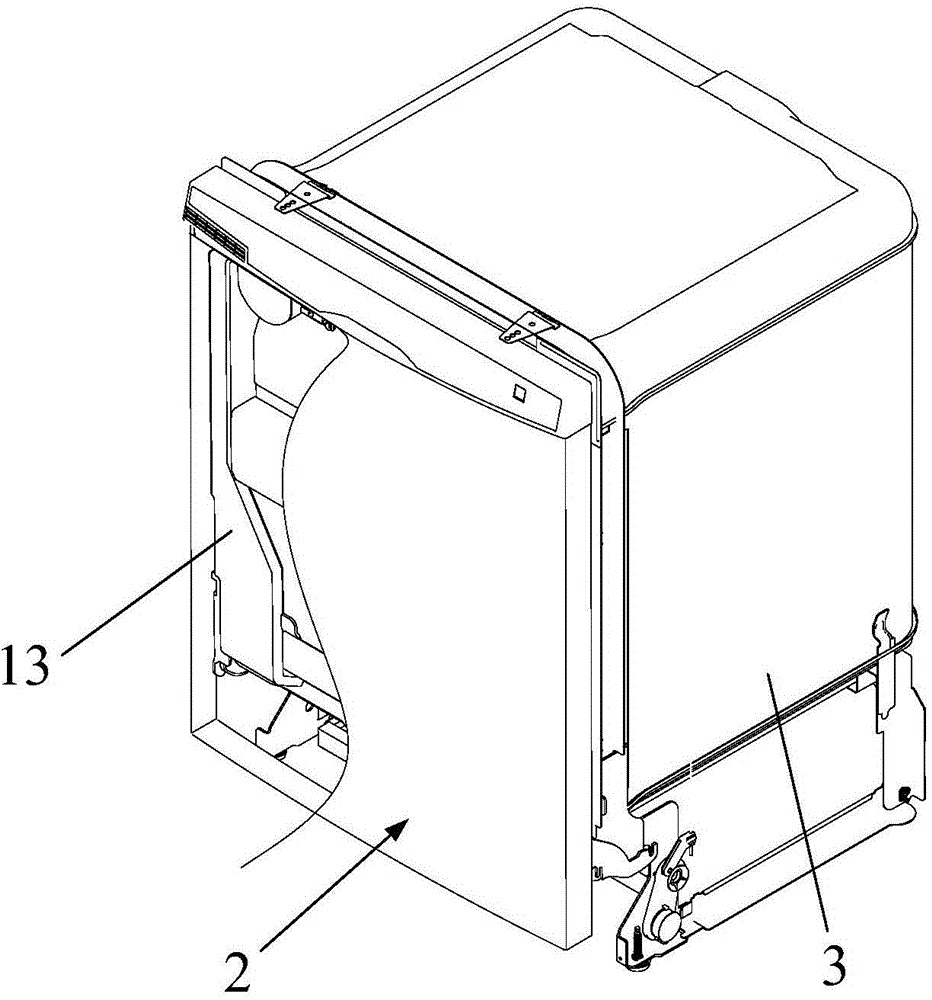

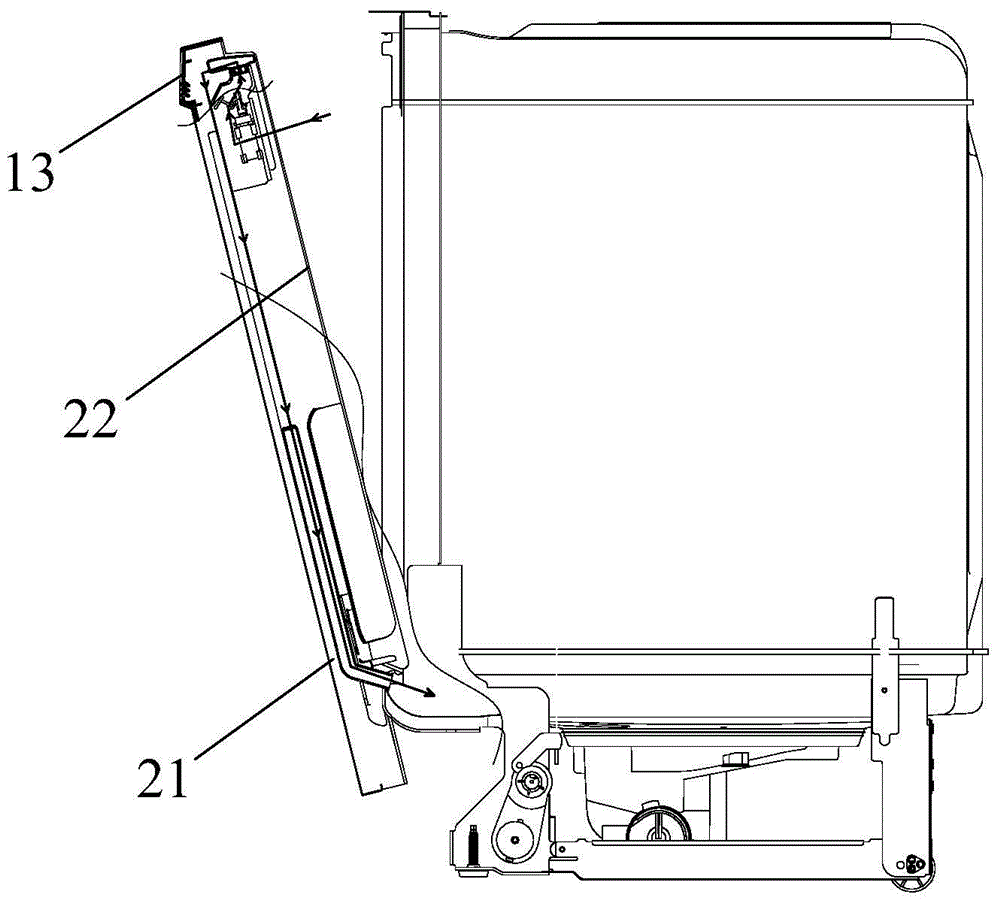

[0050] Such as figure 1 with figure 2As shown, the dishwasher includes an inner container 3 which encloses a washing cavity for placing and washing tableware. An opening is provided in front of the inner container 3, and a door body 2 for closing the aforementioned opening is arranged at the opening, and a cavity is jointly surrounded by the door body 2 and the inner container 3. The door body 2 has an outer door shell 21 and an inner door liner 22 , the door shell 21 and the door liner 22 are fitted together, and an accommodation cavity is formed between the door liner 22 and the door shell 21 .

[0051] In this embodiment, at least one condensation drying system 1 is disposed in the accommodation cavity formed between the door liner 22 and the door shell 21 .

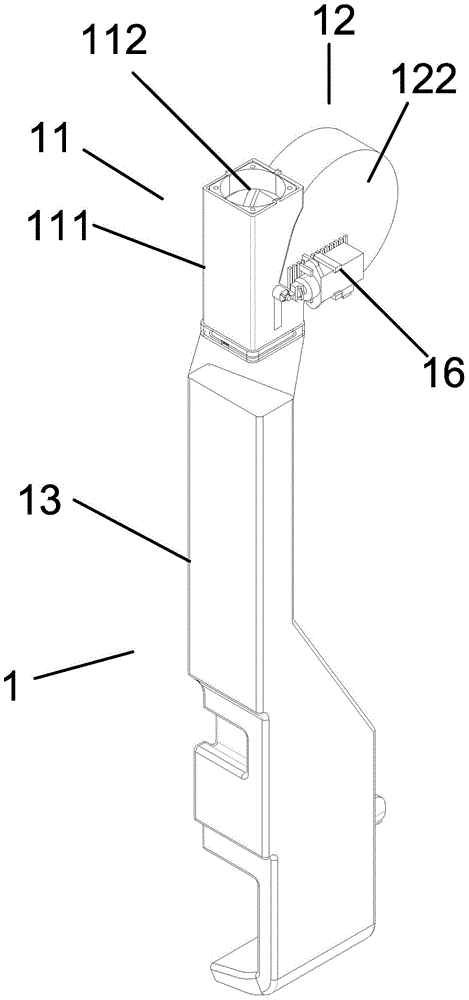

[0052] Specifically, such as Figure 3 to Figure 6 As shown, the condensation drying system 1 includes an air extraction device 11 and a collection chamber 12 for collecting the gas in the washing chamber, the col...

Embodiment 2

[0066] The dishwasher provided in this embodiment is different from the dishwasher provided in Embodiment 1 in that the condensation drying system 1 is located on the outer wall of the inner container 3 . In this solution, the first through hole corresponding to the collection chamber 12 of the condensation drying system 1 and the second through hole corresponding to the return port of the condensation chamber 13 are both arranged on the inner container 3 .

[0067] In addition, the dishwasher provided in this embodiment is the same as the dishwasher provided in Embodiment 1, and will not be repeated here.

[0068] method embodiment

[0069] The condensation drying method provided by the present application is applied to the above-mentioned condensation drying system of the dishwasher, wherein the condensation drying method comprises steps:

[0070] S1. The fan 112 draws external air into the condensation chamber 13 , and when the air passes through the casing 111 , a negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com