Component detection and ammonia spraying control system of SCR denitrification process

A component detection and SCR reactor technology, applied in the field of flue gas denitrification, can solve the problems of high ammonia escape rate, blockage of air preheater, poor injection volume accuracy, etc., and achieve the effect of avoiding ammonia escape and balanced distribution of ammonia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

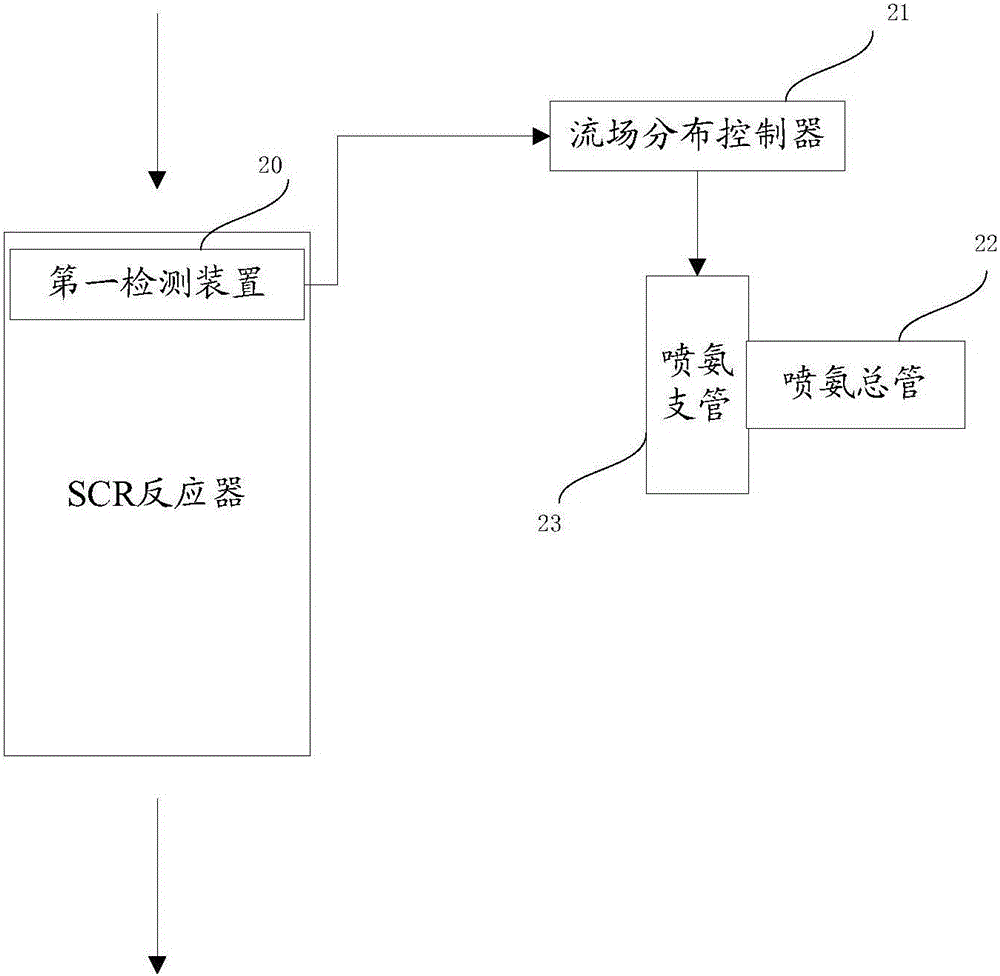

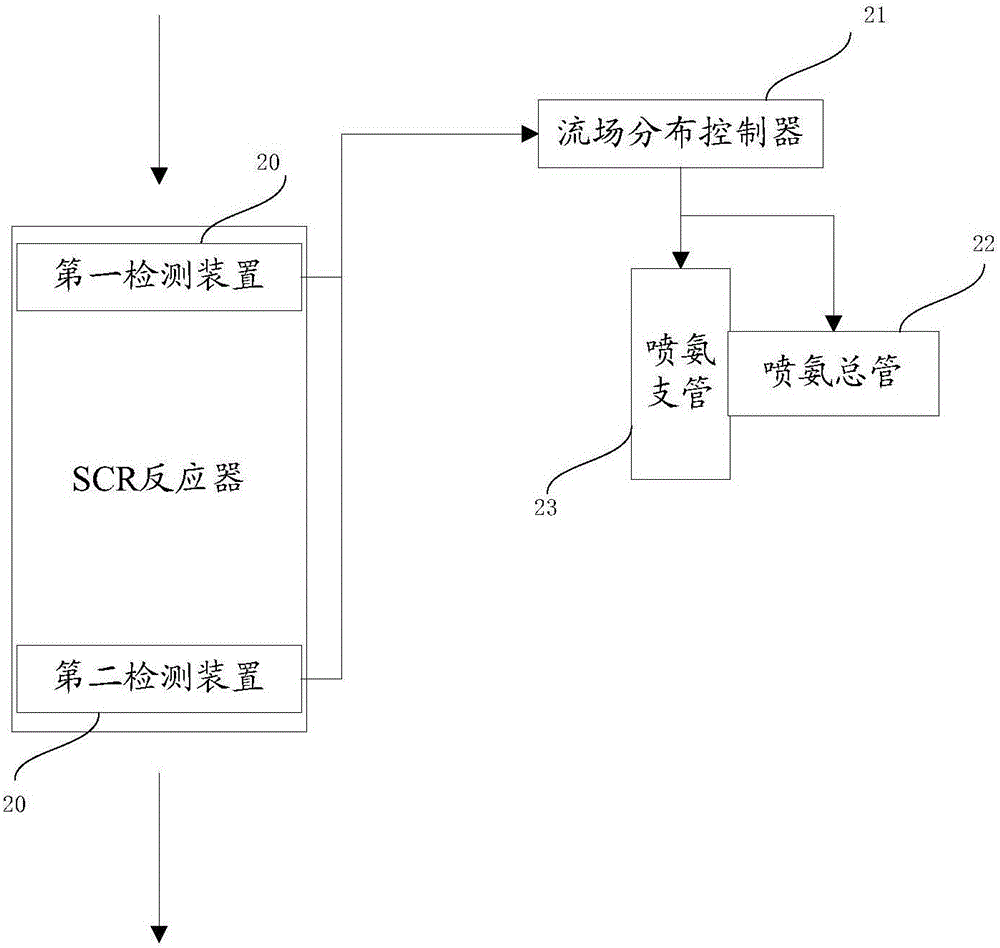

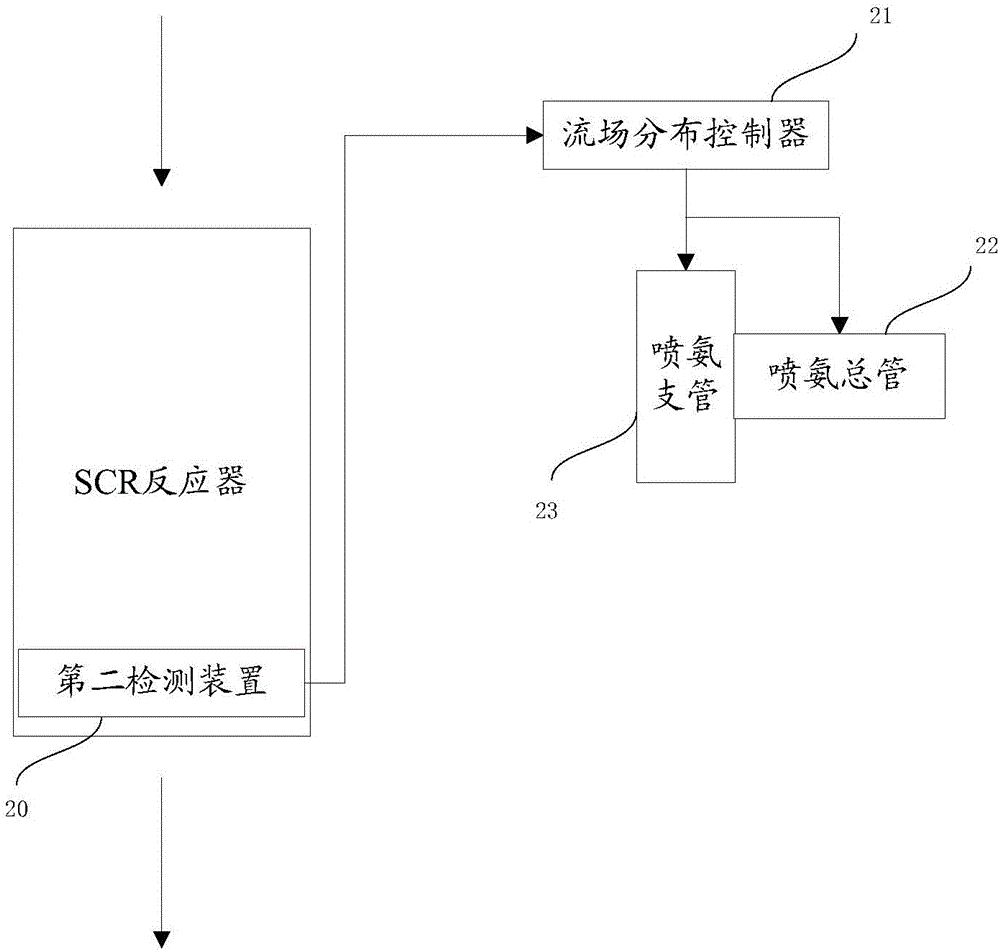

[0026] In the component detection and ammonia injection control system of the SCR denitrification process provided in the embodiment of the present application, a flue gas detection device is installed at the inlet flue and / or outlet flue of the SCR reactor, and the flue gas detection device is provided with multiple sampling heads. The gas composition data can be collected from different positions, and the flow field distribution controller can control the valve opening of the ammonia injection main pipe and the ammonia injection branch pipe according to the gas composition data, so as to accurately control the total amount of ammonia injected into the SCR re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com