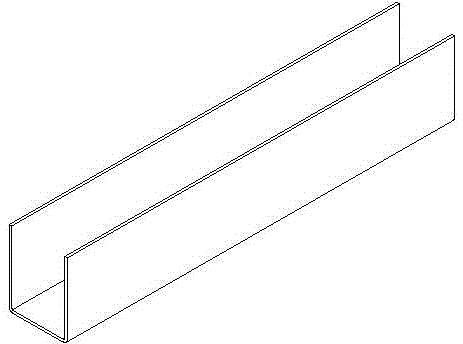

U-shaped beam forming machine with rack type blank centring devices

A centering device and rack-type technology, applied in the field of U-shaped beam forming machines, can solve the problems of high cost, high labor intensity, and different plate thicknesses, etc., and achieve ingenious connection technology, flexible rolling, and fast forming speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

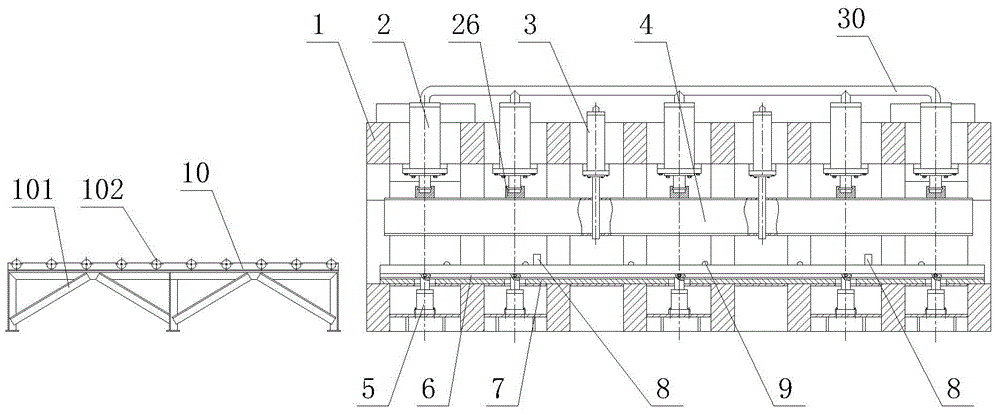

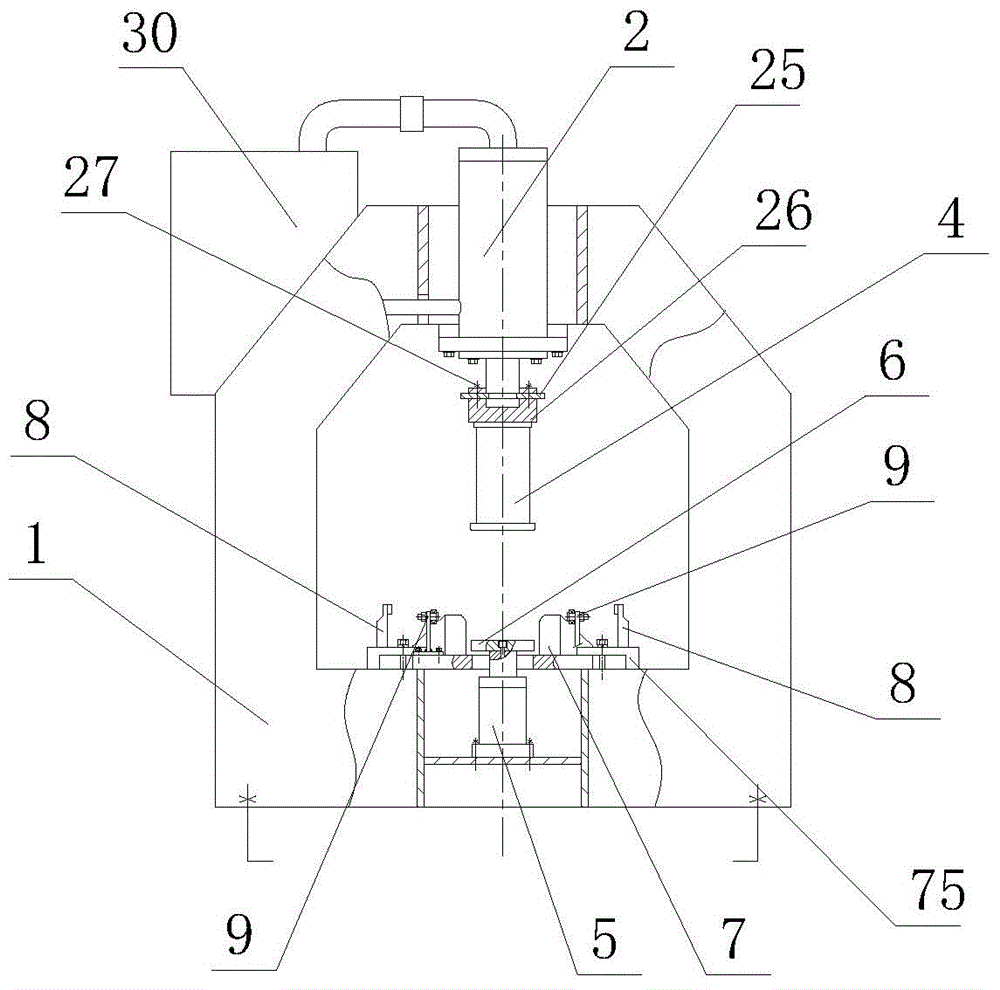

[0031] Such as figure 2 , image 3 As shown, a U-shaped beam forming machine with a rack-type blank centering device includes a frame 1, a bending cylinder 2, an upper mold 4, a lower mold 7, an upper demoulding cylinder 3, a lower demoulding cylinder 5, Hydraulic system 30, rack-type blank centering device 8, booster device 9 and front platform 10, the cylinder bodies of the multiple bending cylinders 2 are connected to the upper beam of the frame 1; the bending cylinders 2 The piston rod is connected with the upper mold 4 through the piston connection seat 26, the insert pin 25, and the bolt 27; The piston rod of the oil cylinder 3 can pass through the inside of the upper mold 4 during telescopic activities. After the upper mold 4 is ejected, if the U-shaped beam can clamp the upper mold 4, the upper demoulding cylinder 3 is started at this time, and the piston rod of the upper demoulding cylinder is extended. The U-shaped beam will be pushed down to solve the problem of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com