Aluminosilicate glass, its preparation method and application

A technology of aluminosilicate glass and liquid glass, applied in optics, instruments, nonlinear optics, etc., can solve the problems of glass covers failing to achieve the original goal of protecting display equipment, broken glass covers, and reduced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The above-mentioned preparation method of aluminosilicate glass greatly reduces or controls the introduction of coloring elements Fe and S by adjusting the composition of raw materials, added clarifiers and heating methods, so that the glass is colored amber or sulfur or brown-yellow or colored Factor (FeS x ) content is reduced, so that the visible light transmittance of the glass is high, the glass color index is basically close to neutral color, and the visible light transmittance is high.

[0049] A strengthened glass according to one embodiment is obtained by strengthening the above-mentioned aluminosilicate glass.

[0050] Preferably, it is strengthened by means of chemical strengthening. Since the total mass percentage of alkali metal oxides in the aluminosilicate glass is greater than or equal to 9% and less than or equal to 23%, the content of alkali metal oxides is relatively high, which is convenient for chemical strengthening treatment.

[0051] A glass pl...

Embodiment 1~20

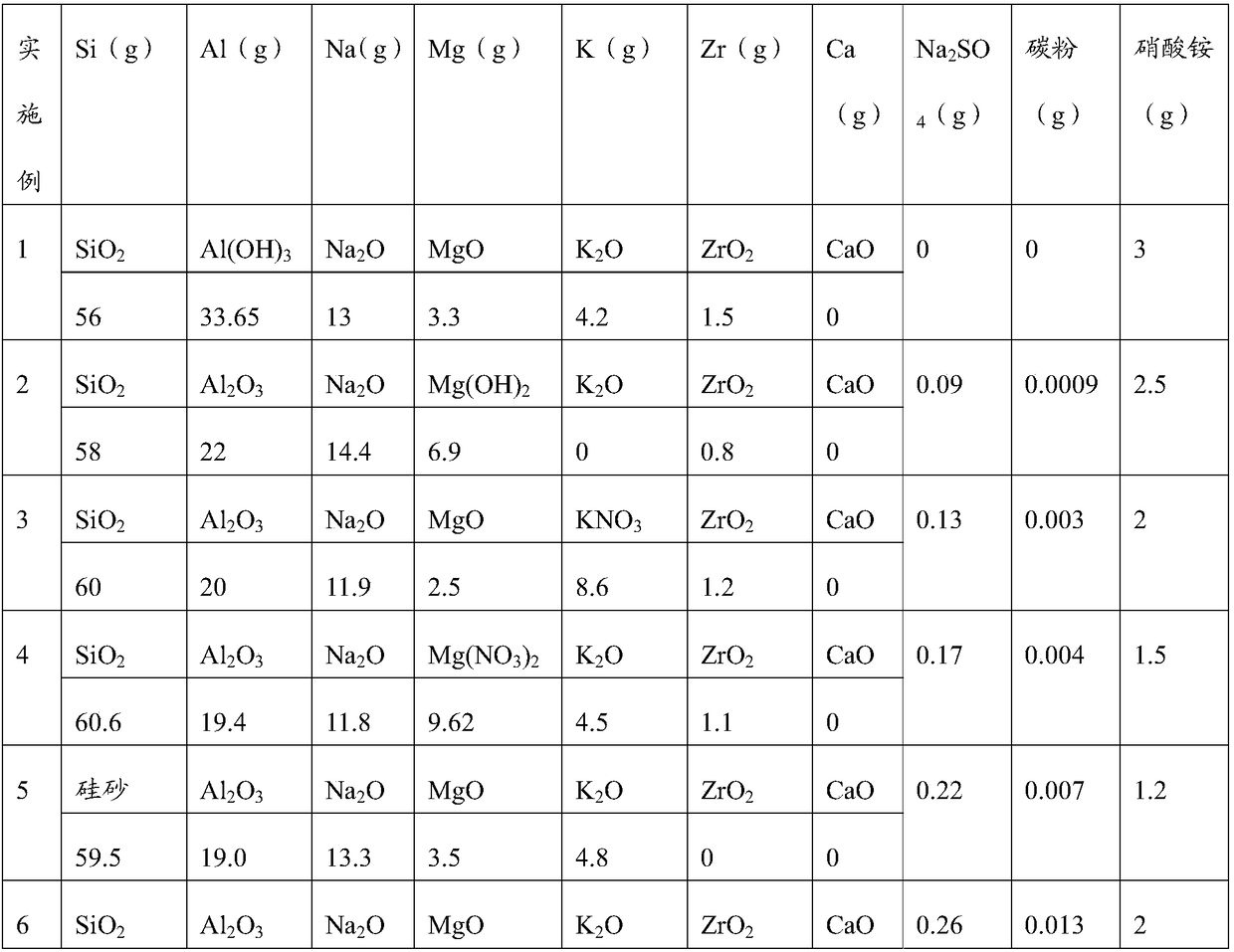

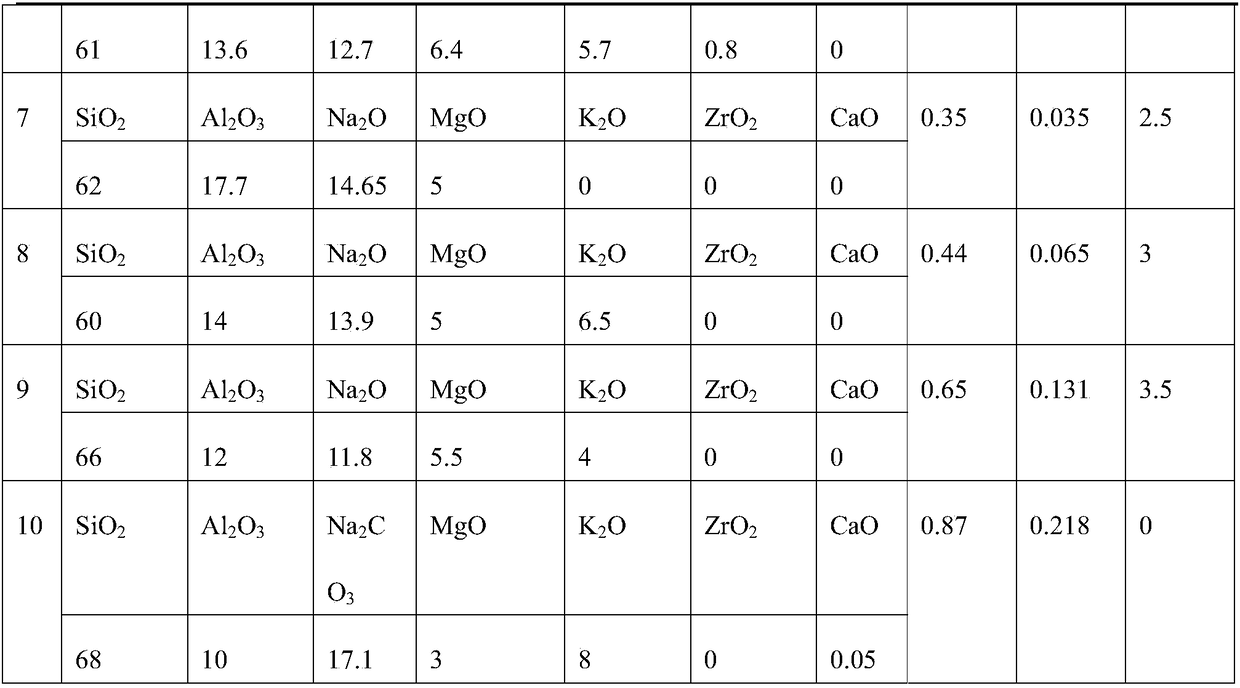

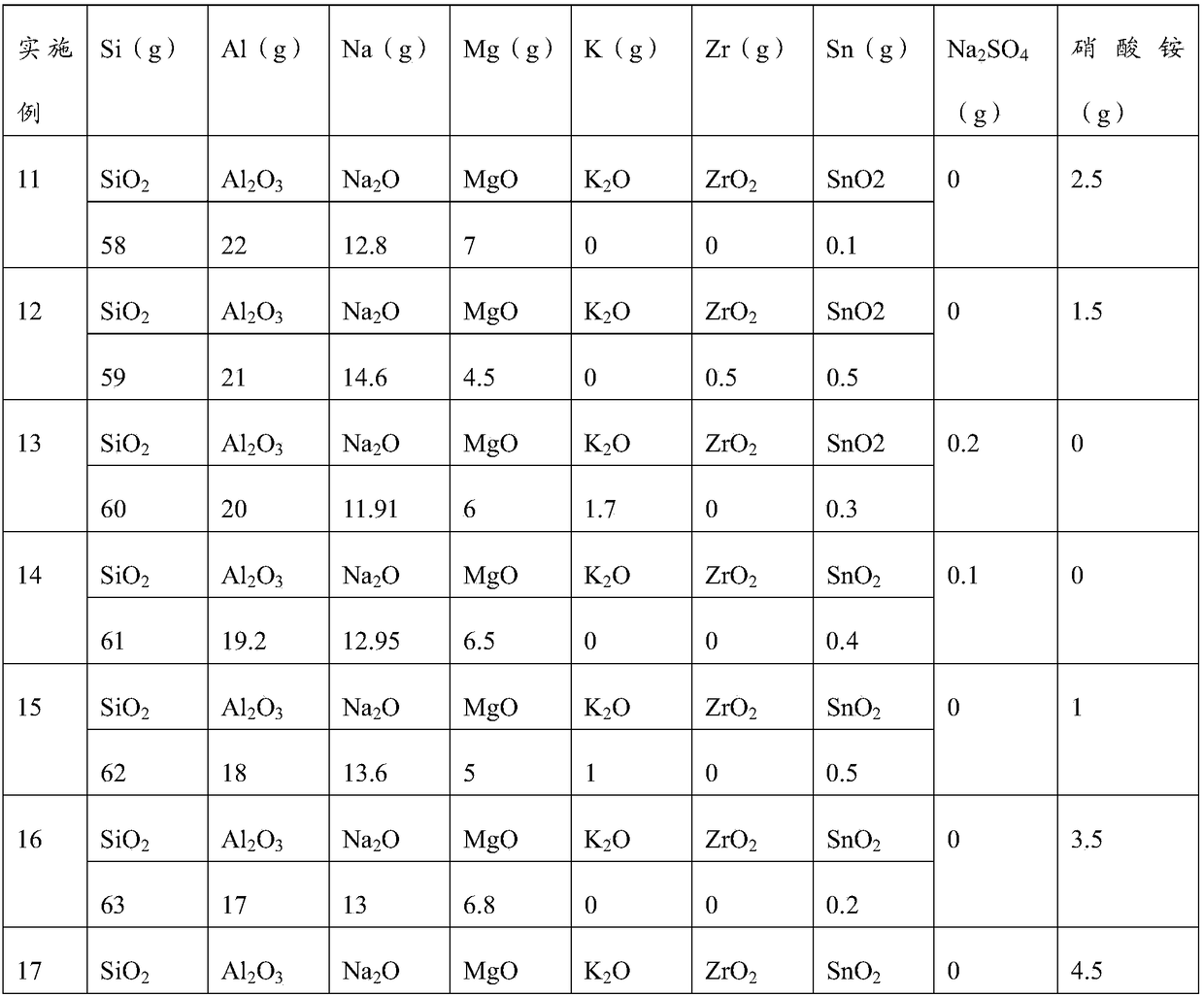

[0056] For the aluminosilicate glasses of Examples 1-10, weigh the corresponding raw materials according to the proportions in Table 1, and for the aluminosilicate glasses of Examples 11-20, weigh the corresponding raw materials according to the proportions in Table 2, and mix thoroughly Finally, put it into a platinum crucible, and carry out melting and clarification for 6 hours under a high-temperature electric furnace at 1620°C. The molten glass is poured into a graphite mold to shape, and kept at 650°C for half an hour, and then cooled to room temperature with the furnace to obtain a glass block. After mechanical cutting, rough grinding, fine grinding, and polishing, it becomes a sheet glass with a thickness of 1.1mm. The composition of the final glass (including Fe 2 o 3 with SO 3 ) is tested by XRF, and the results are shown in Table 3 and Table 4 in terms of the mass percentage of the oxide standard;

[0057] Table 1

[0058]

[0059]

[0060] Table 2

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com