Twisting machine

A twisting machine, organic technology, applied in textiles and papermaking, etc., can solve the problems of twisting thread not meeting product requirements, high labor intensity, high rework rate, and achieve the effect of concise design, convenient operation, and increased output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

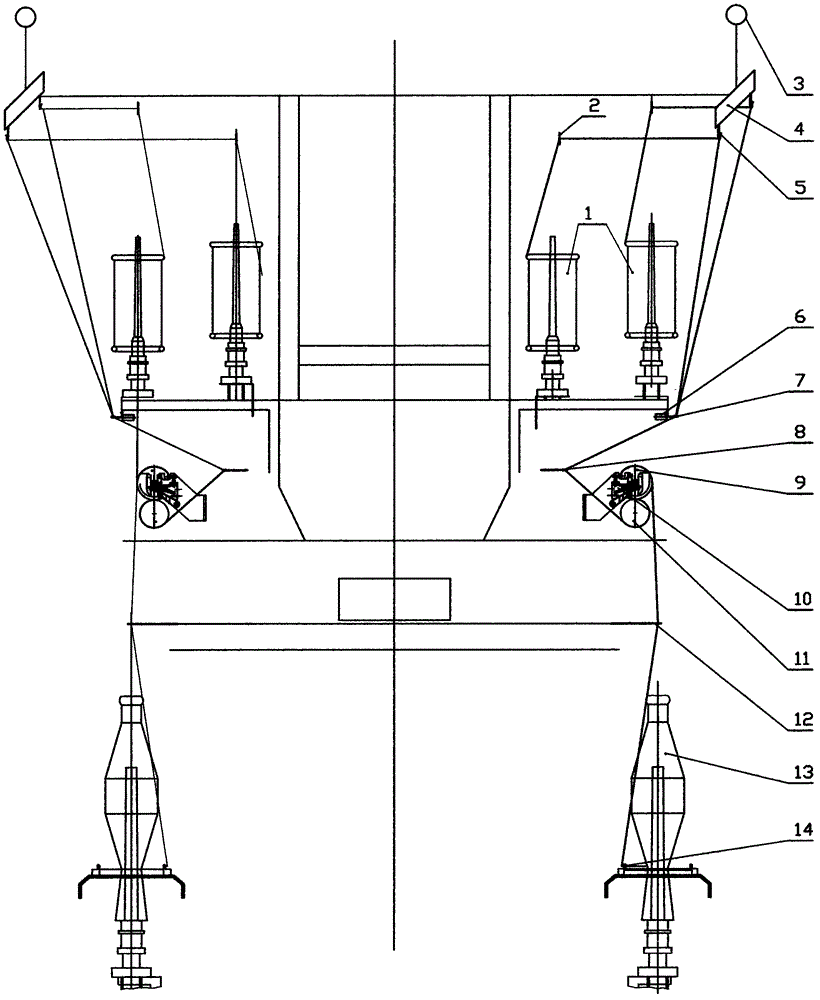

[0024] In order to better understand the technical solutions of the present invention, the following detailed descriptions are given through specific embodiments in conjunction with the drawings:

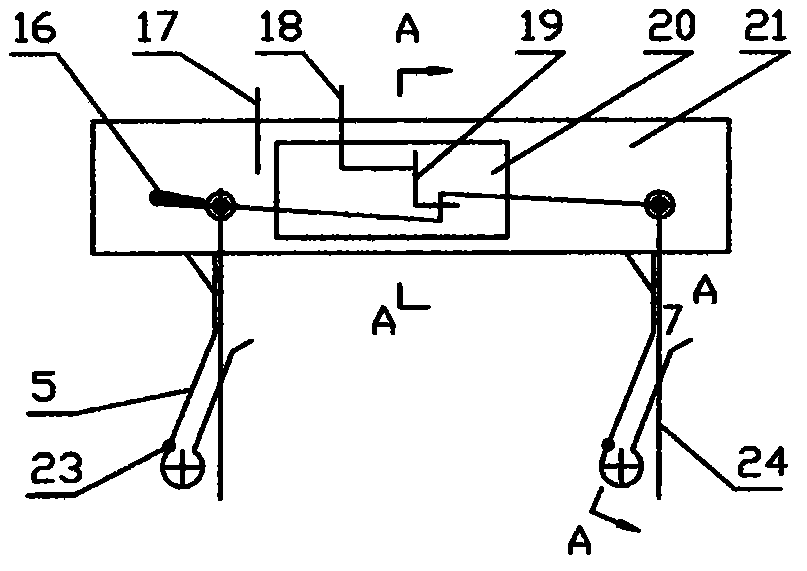

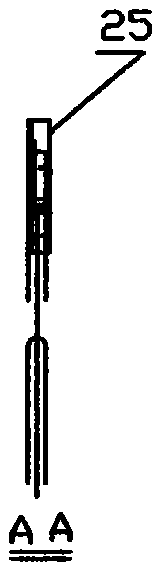

[0025] See first figure 1 It is a schematic diagram of the mutual position of the broken wire switch 4, the wire breaking device 6, the wire winding switch 10, and the wire break and wire indicator lights of the present invention; Figure 2 to Figure 4 It is a schematic diagram of broken wire switch 4, Figure 5 to Figure 8 Is a schematic diagram of the wire breaking device 6; Figure 9 to Figure 13 Schematic diagram of wire wrap switch. among them:

[0026] Figure 2 to Figure 4 Broken wire switch 4 shown: on the bottom plate 21 are welded to the left and right, there are guide wire hooks 5, a fixed pin 28, an insulating plate 20 is installed between the fixed contact 19 and the bottom plate 21, there are switch wires A17 and B18 , The pendulum rod 24 is integrated with the arm rod 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com