Washing machine

A washing machine and washing drum technology, applied in the field of washing machines, can solve the problems of increasing the floor area of the washing machine, the installation of various components is not firm, and the distance between the water circuit and the circuit is too close, so as to achieve a compact structure of the circulating water filtration system, convenient separation of water and electricity, and safe operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

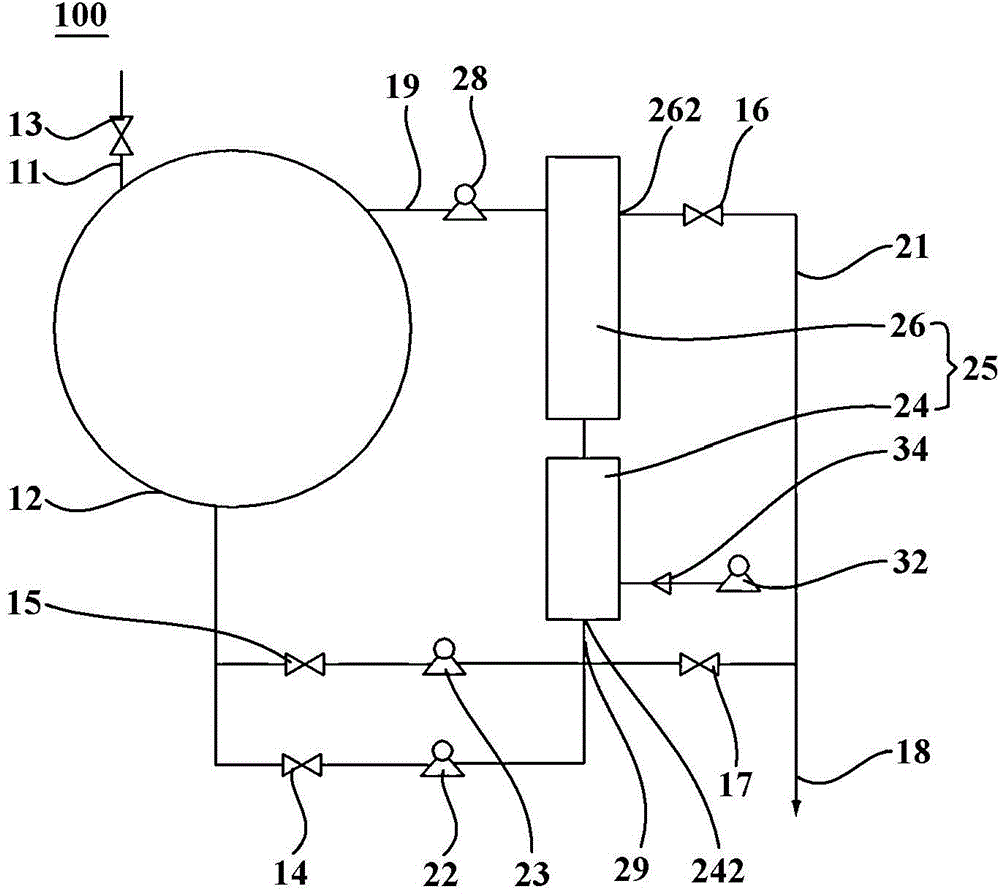

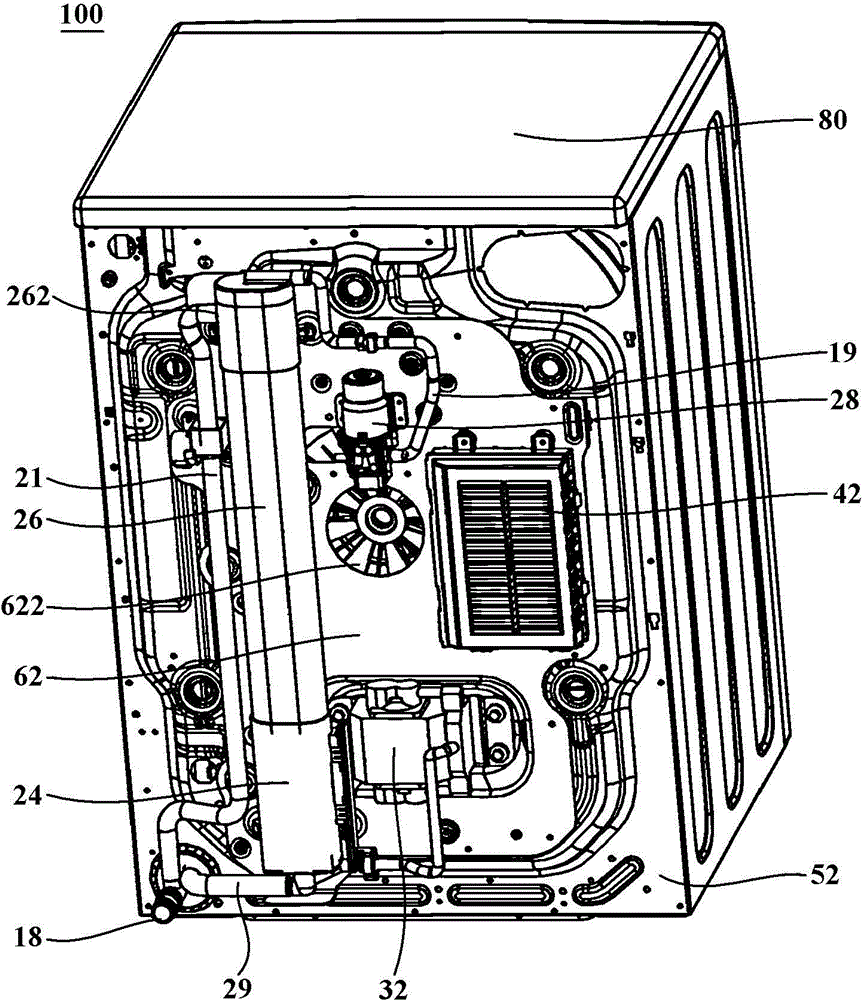

[0043] figure 1 is a schematic principle diagram of a washing machine according to an embodiment of the present invention. see figure 1 , as those skilled in the art can recognize, the washing machine 100 of the embodiment of the present invention, like the existing conventional washing machine, also includes a washing machine casing 80 (see figure 2 ) inside the washing tub 12, the washing tub 12 usually consists of an outer tub and an inner tub that can rotate in the outer tub. The top of the washing tub 12 is provided with a clear water inlet, which is connected to the tap water port by an external water inlet pipeline 11. When the water inlet valve 13 on the external water inlet pipeline 11 is opened, clear water for washing or clear water for rinsing can be entered in the washing tub 12. Usually, a drain is provided at the bottom of the washing tub 12 to drain the water in the washing tub 12 .

[0044] The washing machine 100 of the present invention may further inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com