Portable motor mobile device

A mobile device and portable technology, applied in the field of machinery, can solve problems such as personal safety hazards, people falling and being injured, easy to pry empty, etc., and achieve the effects of easy manufacturing, convenient portability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

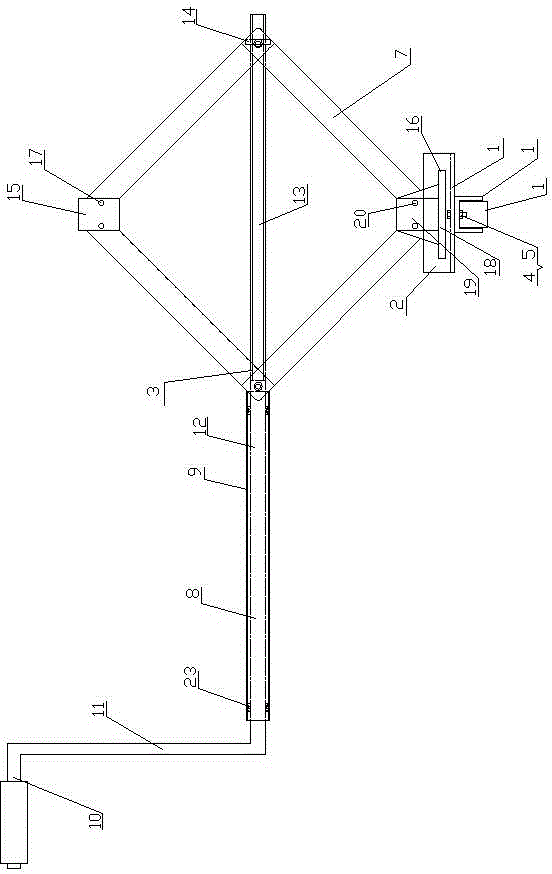

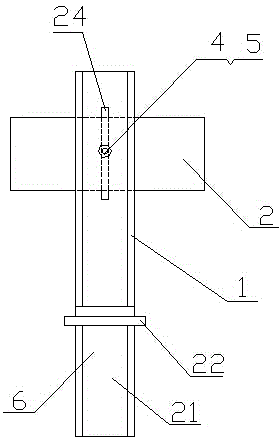

[0012] Such as figure 1 As shown, the portable motor moving device includes a support frame 1, a support base 2, a horizontal jack 3. The support base 2 is fixed on the support frame 1 by bolts 4 and nuts 5. The support frame 1 is arranged vertically when in use, and the support frame The lower part of 1 is used as a plug-in seat 6. The support seat 2 is set horizontally when in use. The support frame 1 and the support seat 2 are respectively a profile channel steel; the horizontal jack 3 includes four first-position mutually hinged arms 7 and a "Z" "" type rocker 8, a sleeve 9, "Z" type rocker 8 includes starting section rod body 10, transition section rod body 11, end section rod body 12, "Z" type rocker 8 starting section rod body 10 is Handle, the end rod body 11 of the "Z" rocker 8 is provided with a screw rod 13, the sleeve 9 is sleeved on the end rod body 12 of the Z-shaped rocker 8, the screw rod 13 extends out of the sleeve 9, the screw rod 13 passes through the two di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com