A rotor core structure of electric excitation brushless DC motor

A brushed DC motor, rotor core technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts, manufacturing stator/rotor body and other directions, can solve the problems affecting the effective power of the motor, reducing the motor efficiency, etc. Good performance, improve motor efficiency, increase the effect of main magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

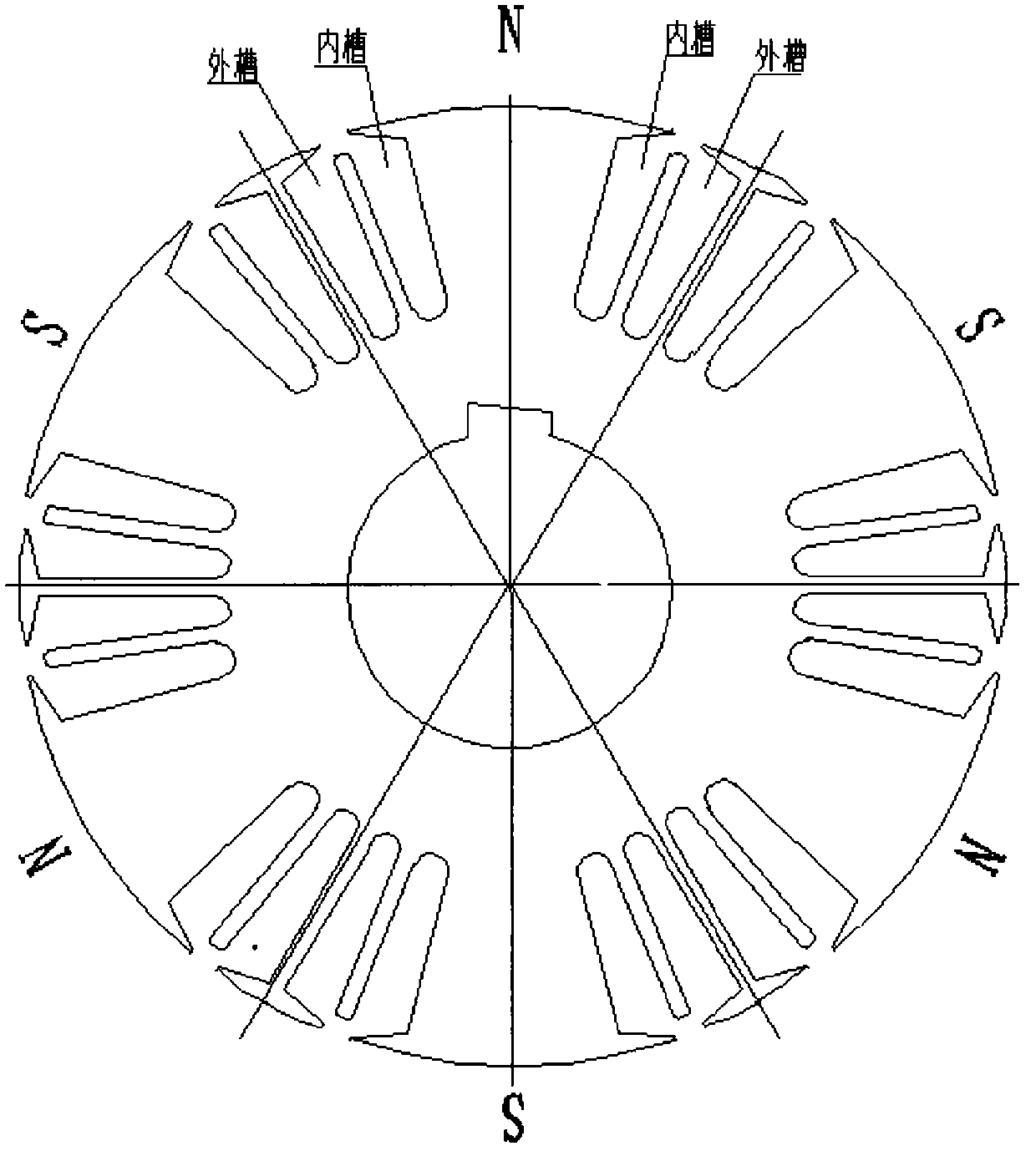

[0011] The rotor core structure of an electrically excited brushless DC motor according to the present invention, as shown in Figure 1, punches or processes the field winding slots on the rotor core, and the field winding slots of each pole are symmetrically distributed on two sides of the center line of the magnetic poles. On the side, remove the iron core near the notch in the middle of the inner and outer grooves on both sides of the center line of each pole to form a large notch, which can be called a public notch. The public notch separates the inner and outer grooves. The magnetic circuit is equivalent to increasing the reluctance, forcing the magnetic field lines grown in the outer groove to pass through the polar arc surface between the two common grooves as much as possible.

[0012] The removed iron core part near the notch in the middle of the inner and outer slots should be properly controlled. The height of the removed iron core is about 3 to 5 times the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com