Wheat sowing and fertilizer applying machine

A fertilizer applicator and wheat technology, applied in the direction of sowing, until sowing, fertilizer and sowing equipment, etc., can solve the problems of affecting the germination rate of seeds, high soil air permeability, and non-concentrated fertilizers, so as to avoid soil moisture evaporation and soil compaction , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

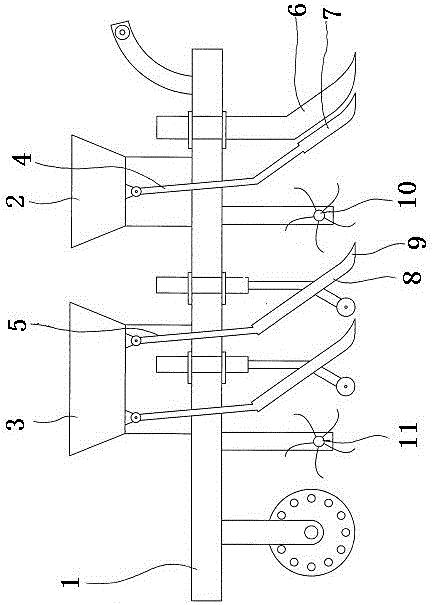

[0022] The wheat sowing and fertilizing machine provided by the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] like figure 1 As shown, the wheat seeding and fertilizing machine includes a frame body 1, a fertilizer box 2 and a seed box 3 are arranged above the frame body 1, a fertilizer guiding pipe 4 is arranged below the fertilizer box 2, and a seed guiding tube 4 is arranged below the seed box 3. The pipe 5 is provided with a fertilizing columbine foot 6 in front of the frame body 1, and a fertilization conduit 7 is arranged behind the fertilization columbine foot 6, and the lower end of the fertilizer guide pipe 4 is inserted in the fertilization conduit 7, and a lower end with The seeding columbine foot 9 of the sowing conduit 8, the lower end of the seed guide pipe 5 is inserted into the sowing conduit 8, the first straw paving mechanism 10 is arranged between the sowing columbine foot 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com