Macroelement water-soluble fertilizer containing polymorphic nitrogen and preparing method of macroelement water-soluble fertilizer

A technology of a large number of elements and polymorphic nitrogen, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problem that urea and nitrate nitrogen materials cannot be directly mixed, and achieve good effect of inhibiting fertilizer dissolution, capillary adsorption, and water solubility. , the effect of preventing soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

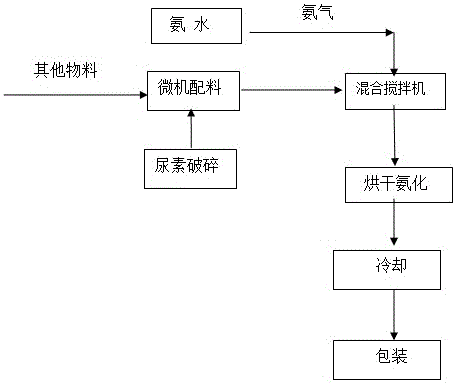

[0028] The preparation method of the described macroelement water-soluble fertilizer containing polymorphic nitrogen comprises the following steps:

[0029] (1) Urea pulverization: pulverize urea to 100-120 mesh;

[0030] (2) Material mixing: add the measured potassium nitrate, ammonium dihydrogen phosphate, potassium dihydrogen phosphate, magnesium nitrate, water-soluble polymer and urea from step (1) into the mixing mixer through the computer batching system, and at the same time After the ammonia water is gasified, it is passed into the material layer of the mixing mixer in proportion, and the uniform mixing time is 3 to 5 minutes;

[0031] (3) Drying ammonification: the mixed material enters the dryer, and the ammoniation treatment of potassium nitrate, ammonium dihydrogen phosphate, and potassium dihydrogen phosphate is completed at the drying temperature, and the outlet gas temperature of the dryer is controlled at 50°C-60°C , the drying time is 15-20min, and the moistu...

Embodiment 1

[0035] Embodiment 1: 14-20-25 high-potassium water-soluble fertilizer, taking 1 ton of product raw material consumption quota as example:

[0036] Raw material name: input amount (kg) nitrate nitrogen % ammonium nitrogen % amide nitrogen % P2O5 % K2O %

[0037] Urea 1296.0

[0038] Ammonia: 892.2

[0039] Potassium nitrate: 3504.916.1

[0040] Ammonium dihydrogen phosphate: 1101.36.7

[0041] Potassium dihydrogen phosphate: 26513.39.0

[0042] Magnesium nitrate: 17

[0043] Polyacrylamide: 20

[0044] Polyacrylate: 20

[0045] Total: 10004.93.56.020.025.1

[0046] According to computer measurement, 129 kg of urea (containing N46.2%, mass percentage, the same below) will be pulverized to 100-120 mesh, 350 kg of potassium nitrate (containing N14%, K2O46%), ammonium dihydrogen phosphate (containing N12%, P2O561%) 110 kg, potassium dihydrogen phosphate (containing P2O550%, K2O34%) 265 kg, magnesium nitrate 17 kg, polyacrylamide 20 kg, polyacrylic acid salt 20 kg into the m...

Embodiment 2

[0047] Embodiment 2: 20-30-10 high-phosphorus water-soluble fertilizer, taking 1 ton of product raw material consumption quota as example:

[0048] Raw material name: input amount (kg) nitrate nitrogen % ammonium nitrogen % amide nitrogen % P2O5 % K2O %

[0049] Urea 28513.2

[0050] Ammonia: 461.2

[0051] Potassium nitrate: 1031.44.7

[0052] Ammonium dihydrogen phosphate: 3654.422.3

[0053] Potassium dihydrogen phosphate: 1557.85.3

[0054] Magnesium nitrate: 10

[0055] Polyacrylamide: 20

[0056] Polyacrylate: 16

[0057] Total: 10001.45.613.230.110.0

[0058] After microcomputer measurement, crush 285 kg of urea (containing N46.2%, mass percentage, the same below) to 100 mesh-120 mesh, 103 kg of potassium nitrate (containing N14%, K2O46%), ammonium dihydrogen phosphate (containing N12%, P2O561%) 365 kg, potassium dihydrogen phosphate (containing P2O550%, K2O34%) 155 kg, magnesium nitrate 10 kg, polyacrylamide 20 kg, polyacrylic acid salt 16 kg were added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com