Method for producing flos rosae rugosae hydrosol

A technology of rose hydrosol and production method, which is applied to the functions of food ingredients, food heat treatment, food ingredients containing natural extracts, etc., and can solve the problems of products needing to be refrigerated, short shelf life, and poor sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Using a low-temperature vacuum circulation extraction device to distill and extract rose dew from fresh roses at 30°C;

[0026] (2) Ultra-high temperature equipment preparation stage: After confirming that the parameters of the equipment are within the normal range, then connect the power supply, water source and air source, and start the ultra-high temperature equipment normally;

[0027] (3) Sterilization in place (SIP): Set the pump speed to 45Hz, the material pump pressure to 5bar, set the heating temperature of the first section to 120°C, and the heating temperature of the second section to 152°C, and wait until the temperature of the buffer tank reaches the specified When the temperature is measured, time it for 10 minutes or longer;

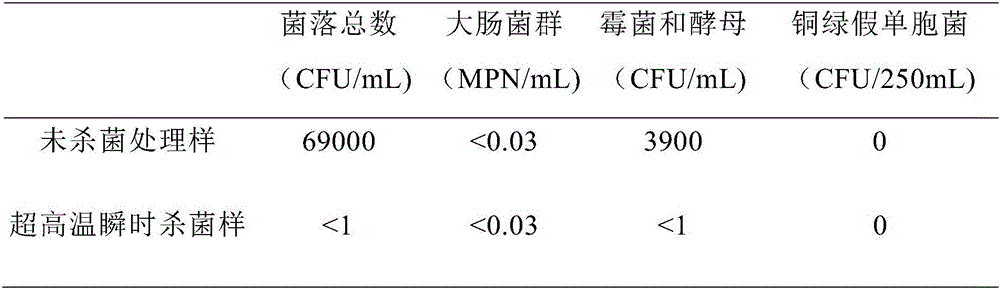

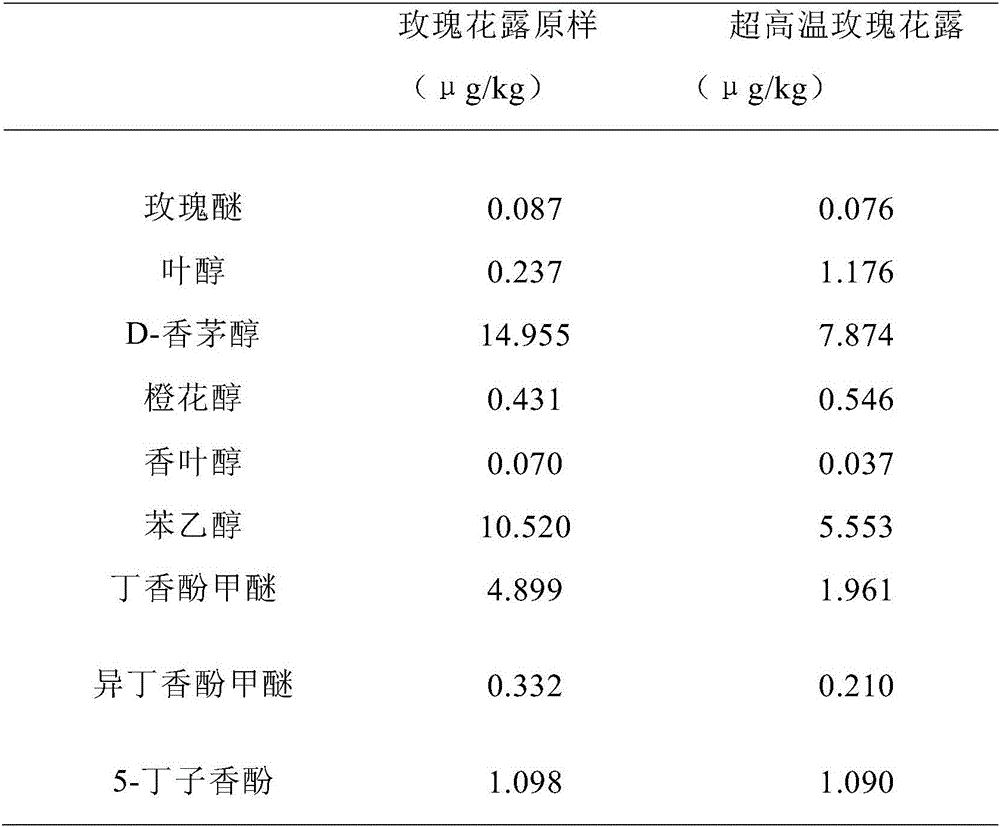

[0028] (4) Product production: add the rose water obtained in step (1) into the balance tank, and when the rose water reaches the sterilization temperature (85° C.) of the first stage, enter the sterilization temperature (135° C...

Embodiment 2

[0035] (1) Using a low-temperature vacuum circulation extraction device to distill and extract rose dew from fresh roses at 40°C;

[0036] (2) Ultra-high temperature equipment preparation stage: After confirming that the parameters of the equipment are within the normal range, then connect the power supply, water source and air source, and start the ultra-high temperature equipment normally;

[0037] (3) SIP sterilization: set the pump speed to 45Hz, the material pump pressure to 5bar, set the heating temperature of the first stage to 120°C, and the heating temperature of the second stage to 152°C. When the temperature of the buffer tank reaches the specified temperature, Timing for 10 minutes or longer;

[0038] (4) Product production: add the rose water obtained in step (1) into the balance tank, and when the rose water reaches the sterilization temperature (90°C) of the first stage, it enters the sterilization temperature (140°C) of the second stage , and keep the steriliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com