Down sterilizing device

A sterilization and disinfection device and high-temperature sterilization technology, applied in heating and other directions, can solve the problems of incomplete disinfection, inability to complete disinfection and sterilization, weak irradiation penetration ability, etc., and achieve effective down sterilization and disinfection, simple structure and odor removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred modes of the present invention will be described in further detail below in conjunction with the examples.

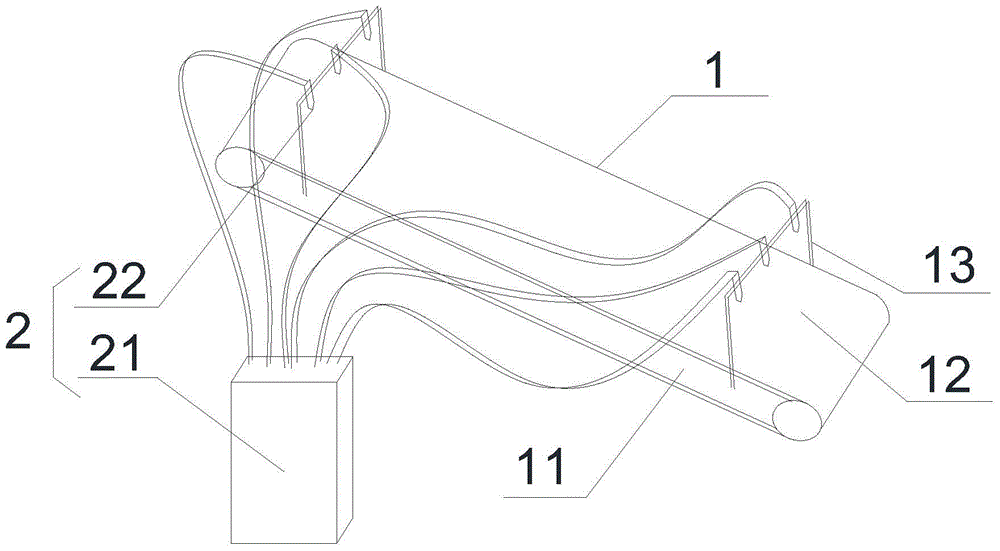

[0012] Such as figure 1 As shown, a down sterilization and disinfection device includes a conveyor belt 1 and a high-temperature sterilization and disinfection assembly 2. The conveyor belt 1 includes a conveyor belt body 11 and a conveyor surface 12 located on the periphery of the conveyor belt body 11. Several inverted " U"-shaped frame 13, the two ends of the frame 13 are respectively connected with the two side walls of the conveyor belt body 11; The gas delivery pipe 23 is connected to several spray heads 22 , and the spray heads 22 are fixed on the top of the frame 13 .

[0013] In order to further optimize the technical solution, the area of the through holes is not more than 1cm 2 .

[0014] In order to further optimize the technical solution, the number of the frames 3 is two, and they are respectively located at two ends of the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com