A quenched absorption tower

An absorption tower and rapid cooling technology, applied in the field of graphite device production, can solve the problems of insufficient absorption of the absorption tower, uneven liquid distribution, unsatisfactory cooling effect of the absorption tower, etc., and achieve the effect of improving absorption and facilitating full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

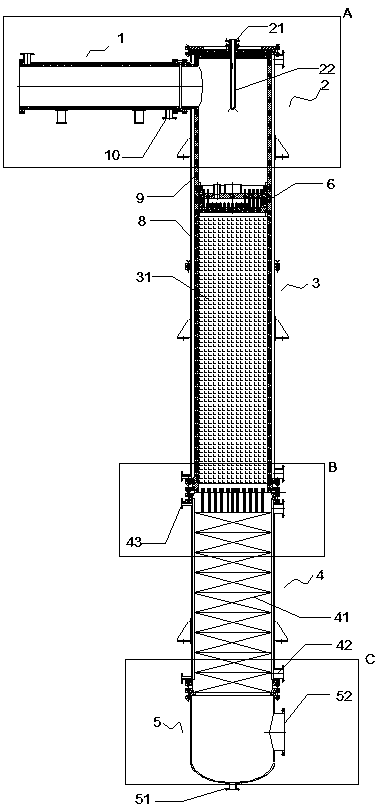

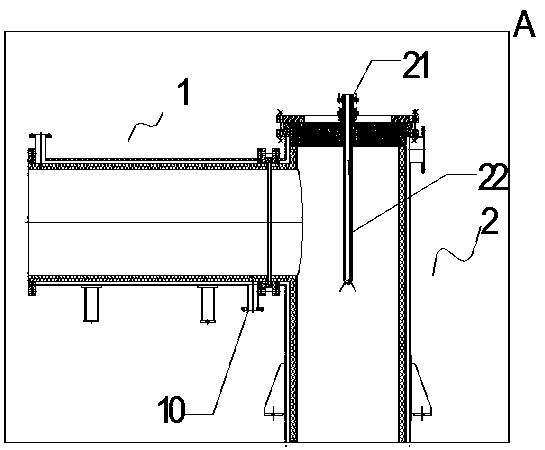

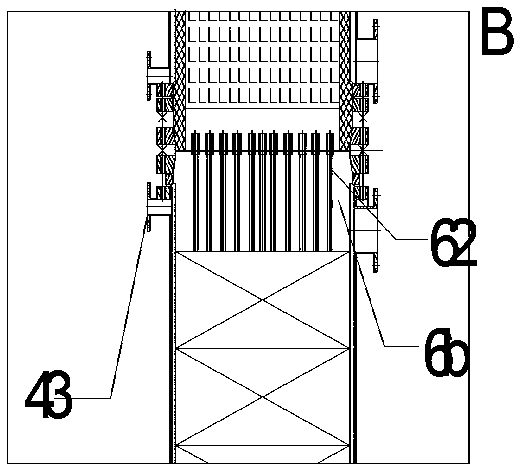

[0023] Such as Figure 1 to Figure 5 A quenching absorption tower shown, the quenching absorption tower includes a steel shell and a graphite lining, and the quenching absorption tower includes: an inlet pipe 1, a spray layer 2, an absorption layer 3, a cooling layer 4 and a discharge layer 5; The spraying layer 2, the absorbing layer 3, the cooling layer 4 and the discharge layer 5 are arranged sequentially from top to bottom.

[0024] The top of the spray layer 2 is provided with a spray port 21, and the spray port 21 is connected with a spray pipe 22 in the vertical direction in the spray layer 2, and the side wall of the spray layer 2 is provided with a pipe interface. The air pipe 1 is vertically connected to the pipe interface on the side wall of the spray layer 2; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com