Multi-station laser engraving equipment with automatic feeding and discharging functions

An automatic loading and unloading, multi-station technology, used in metal processing equipment, welding equipment, laser welding equipment and other directions, can solve the problems of easy to produce work injuries, poor alignment accuracy, low degree of automation, etc., to improve work efficiency, avoid Occupational injury risk, the effect of solving overwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

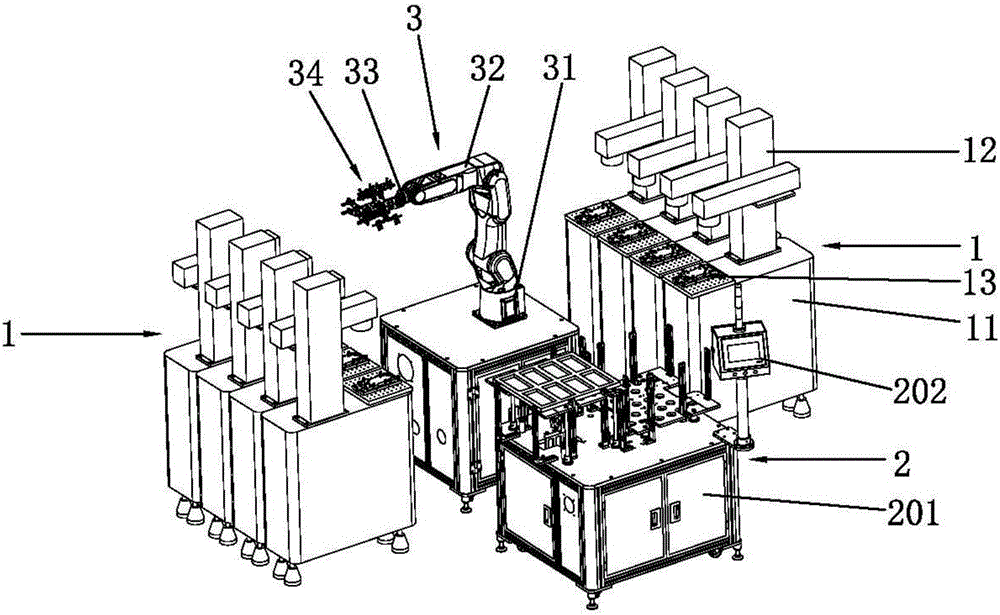

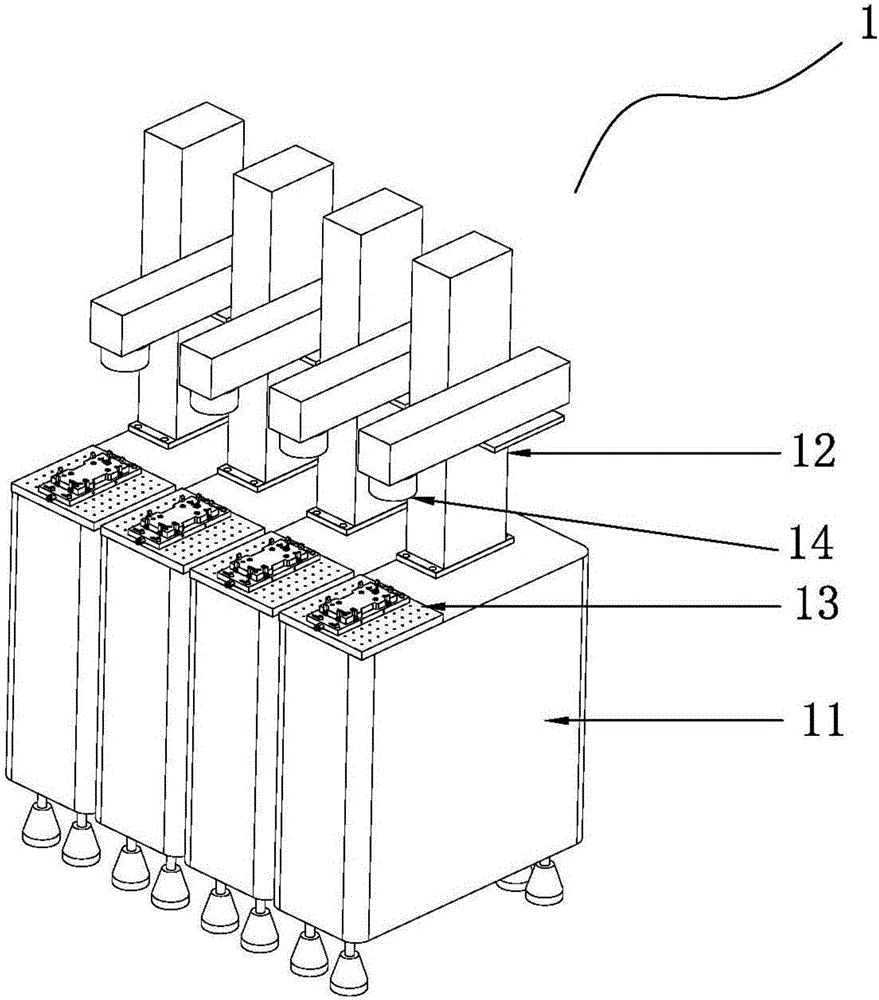

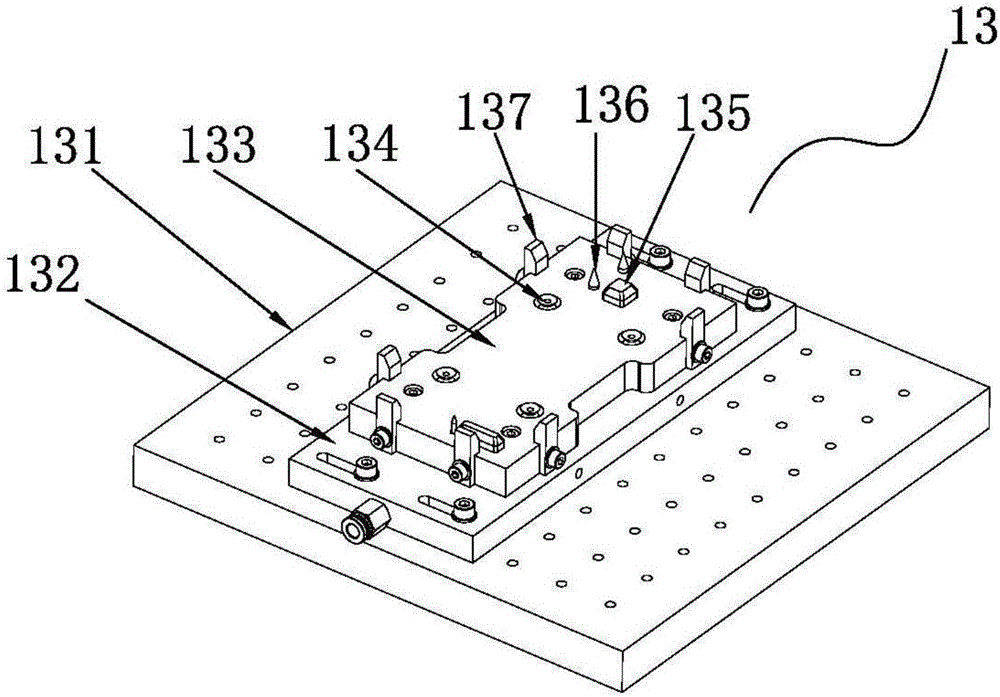

[0046] A multi-station laser engraving device with automatic loading and unloading provided by the present invention includes a laser engraving device 1 with multiple stations, an automatic loading and unloading device 2, and a laser engraving device 1 and an automatic loading and unloading device 2 Space, manipulator 3 for handling materials; such as figure 1 As shown, a laser engraving device 1 is respectively arranged on the left and right sides of the manipulator 3 , and the automatic loading and unloading device 2 is placed in front of the manipulator 3 . During the production operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com