Mobile bearing platform

A carrying platform, mobile technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high cost, high requirements, and high manufacturing price of gear trains, and achieve stable performance, improve work efficiency, and design science. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

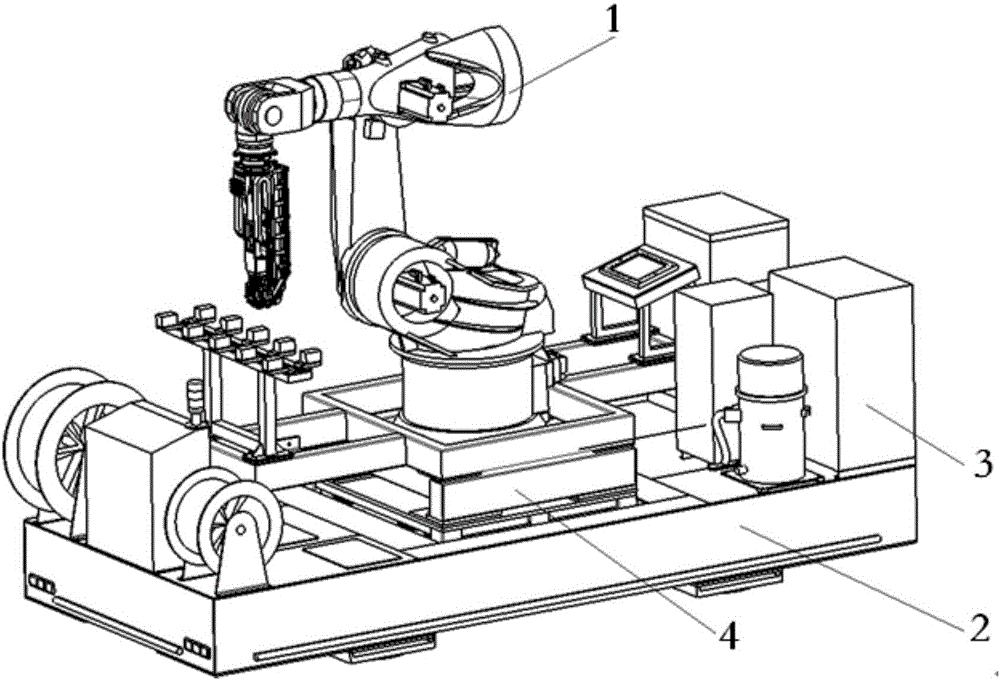

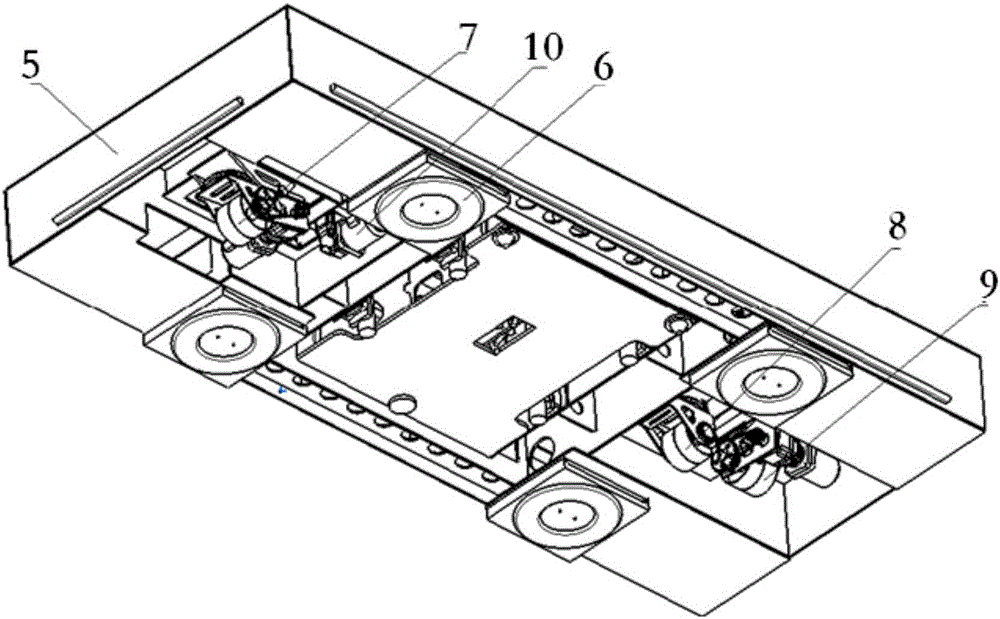

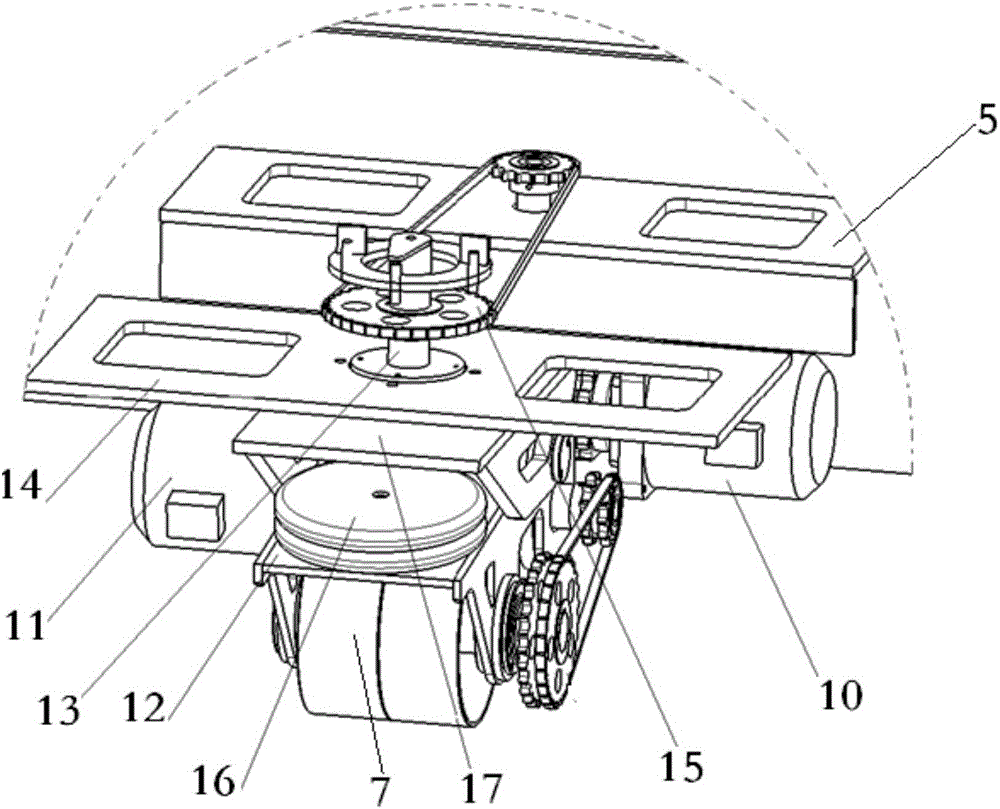

[0017] See attached picture, figure 1 The embodiment provides a general layout diagram of the hole-making equipment using the mobile platform. On the mobile carrying platform 2, a working platform 4 is connected through a hydraulic lifting system, and the hole-making robot 1 working at the end is fixed on the working platform 4. The mobile support platform 2 of the present application contains a load-bearing frame 5, a wheel-loaded drive system, an air cushion support structure 6 and a control system 3, and is characterized in that the load-bearing frame 5 is a rigid structure, and the air-cushion support structure 6 and the wheel-load drive system Located at the bottom of the load-bearing frame, the air cushion support structure and the wheel-loaded drive system are controlled by the control system 3 .

[0018] The mobile load-bearing platform in the figure has four air-cushion support structures 6 evenly distributed on the bottom of the load-bearing frame 5. The air-cushion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com