Automatic celluloid medicine box forming device

A celluloid and driving device technology, applied in the field of stamping and forming, can solve the problems of inability to record process parameters in real time, long debugging and preparation time, and large difference in forming quality, so as to save outsourcing costs, controllable forming quality, and reduce processing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

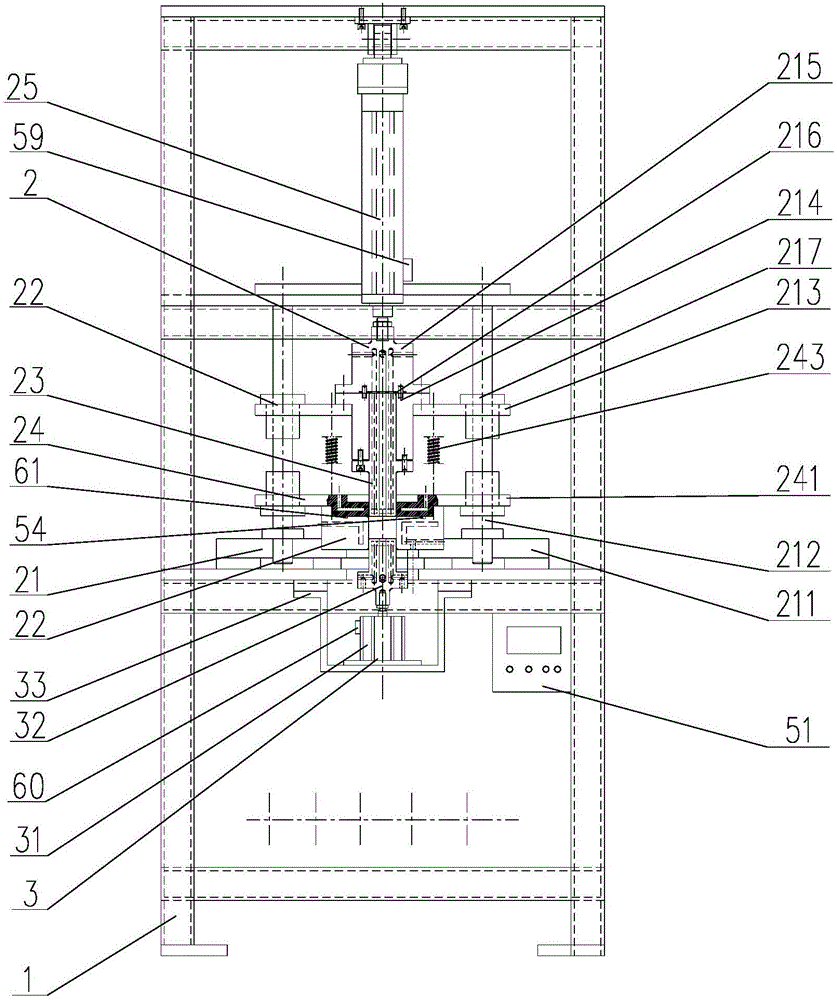

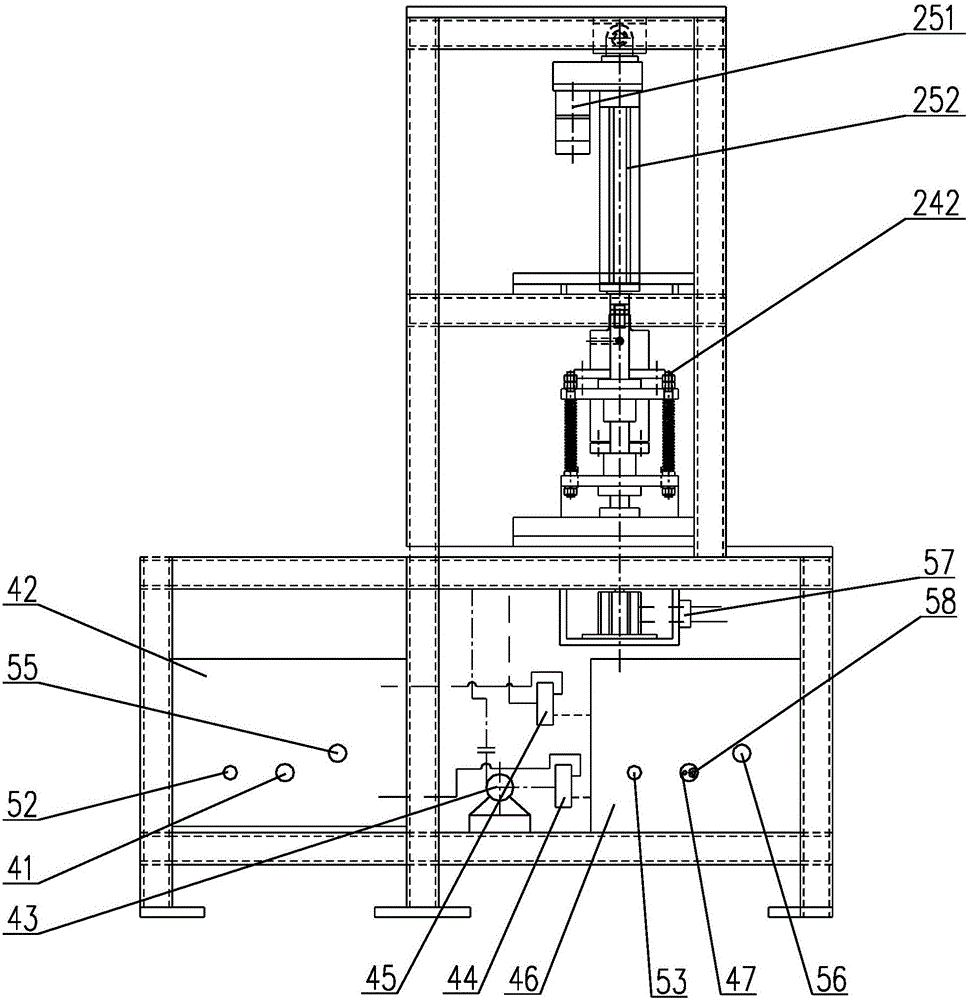

[0032] The automatic forming device of celluloid medicine box includes a frame 1, a stamping device 2 arranged on the frame 1, a demoulding device 3, a heating / cooling oil circulation system and a control system, the stamping device 2 is used for stamping and forming of the medicine box, The demoulding device 3 is used for the demoulding of the stamped medicine box, and the heating / cooling oil circulation system acts on the stamping device 2 and the demoulding device 3 for conformal heating of raw materials and shaping of the stamped medicine box Cooling, the control system is used for the control of stamping process, demoulding process and heating / cooling oil circulation system;

[0033] Stamping device 2 comprises formwork 21, is fixed on the punch 23 of formwork 21, die 22, hold-down device 24 and drive unit 25, formwork 21 comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com